- Home

- Projects Solutions

Feed Production Line

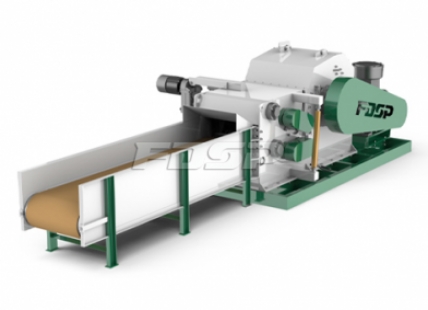

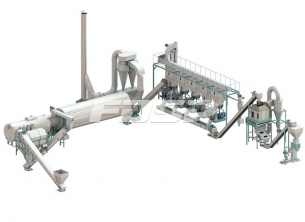

- Small Turnkey Animal Feed Production Line

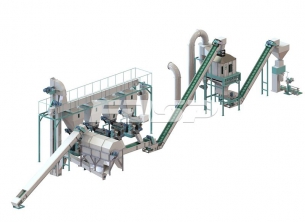

- Poultry & Livestock Feed Production Line

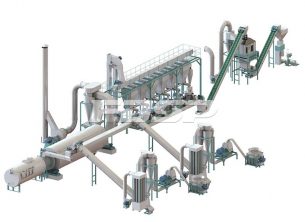

- Pig Feed Production Line

- Ruminant Animal Feed Production Line

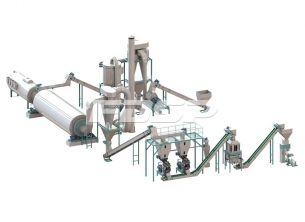

- Floating Fish Feed Extruding Line

- Raw Material Extruding Production Line

- Pet feed engineering

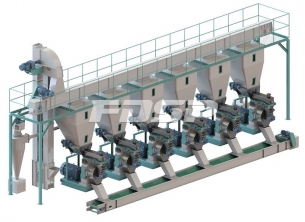

- Premix Feed Production Line

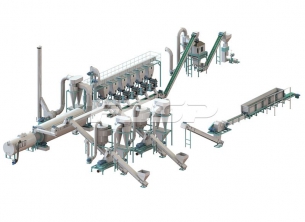

- Concentrated Feed Production Line

- Aqua Fish Feed Production Line

- Products

- Video

- News

- About Us

- Service&Support

- Contact Us