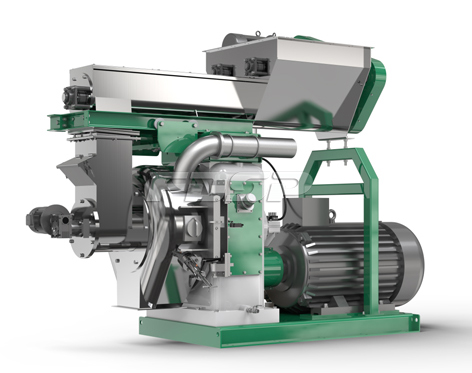

Ring die materials: 4Cr13

Stainless steel feeder: With broken arch function

Door cover of granulating chamber: -6/SUS304

Forced feeding: worm gearing reducer

Gearbox Casing: HT250

Wheel gear: 42CrMo

Gear shaft: 20CrMnMo

Main shaft: 40Cr

Hollow shaft: forge piece 45#

Bearing: gear shaft, main shaft bearing is NSK, roller bearing is domestic high quality bearings

Oil seal: Germany/Taiwan

Overload mechanical protection: safety pin

Serpentine spring coupling drive

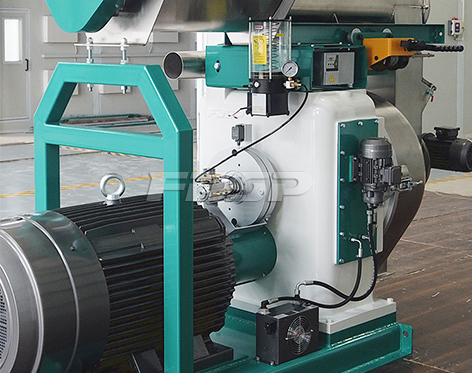

Lubrication system: Automatic oil filling system is available

Morot: Siemens (China) motor or Wannan motor