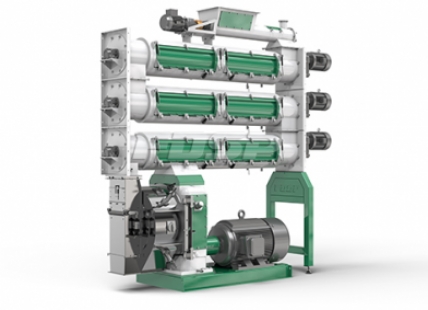

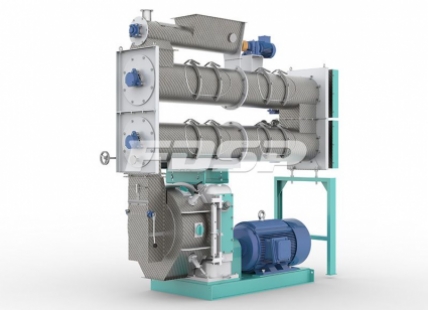

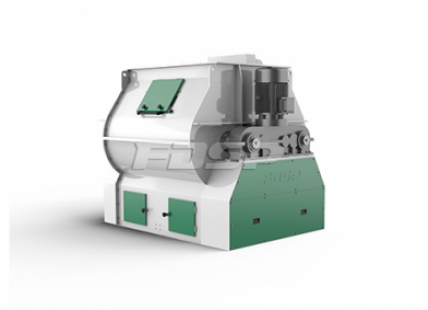

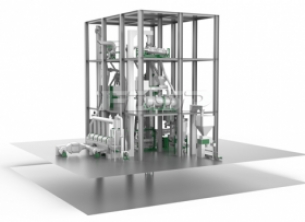

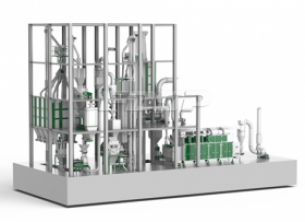

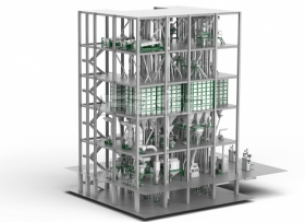

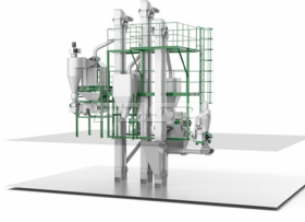

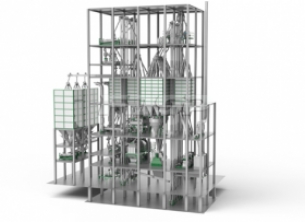

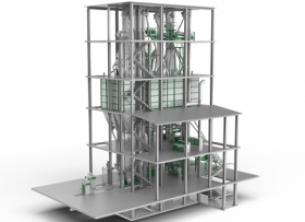

Feed Grinder SWLF Series Vertical Pulverizer

SWFL series vertical pulverizer is a kind of superfine pulverizing processing equipment. It is suitable for all kinds of large, medium and small feed mills. After primary screening, magnetic separation and mixing of various coarse materials such as corn, sorghum, rice, soybean meal, fish and shrimp ,the materials enter the pulverizer to achieve the required standard ultra-fine materials, especially suitable for ultra-fine pulverization of shrimp, turtle, carp and young animal feed.