- Home

- Projects Solutions

Feed Production Line

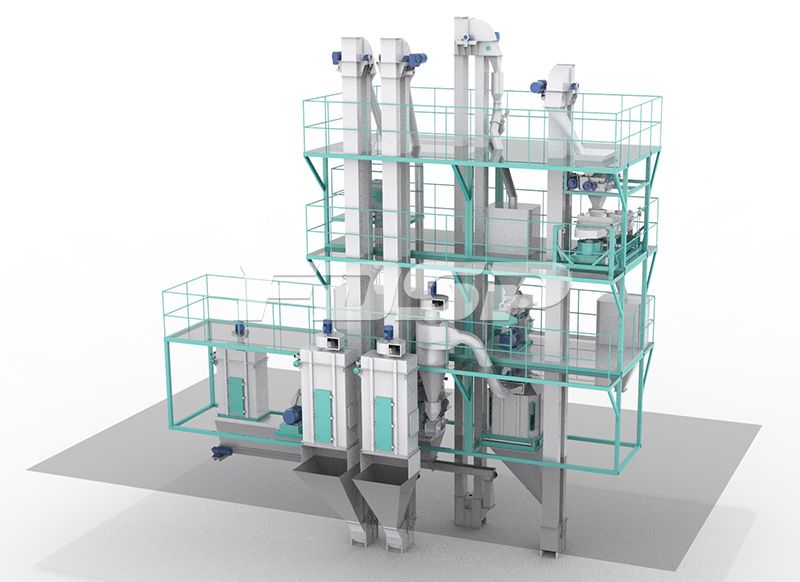

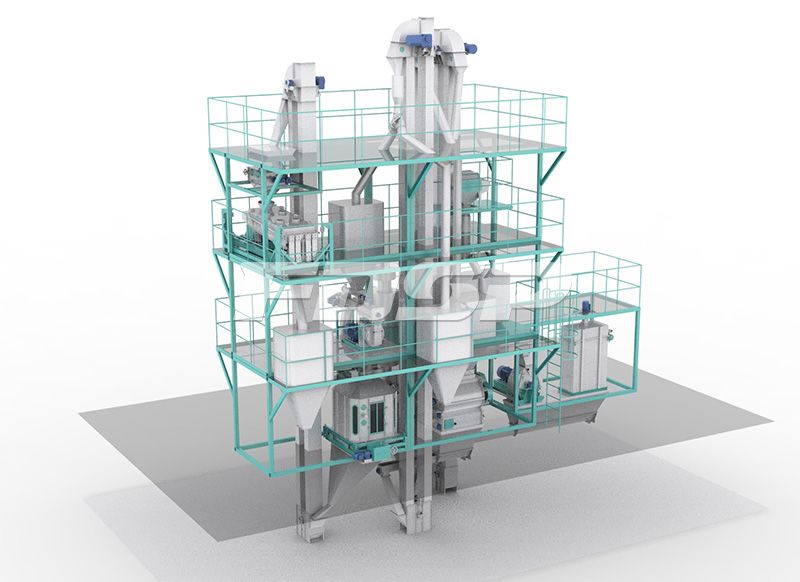

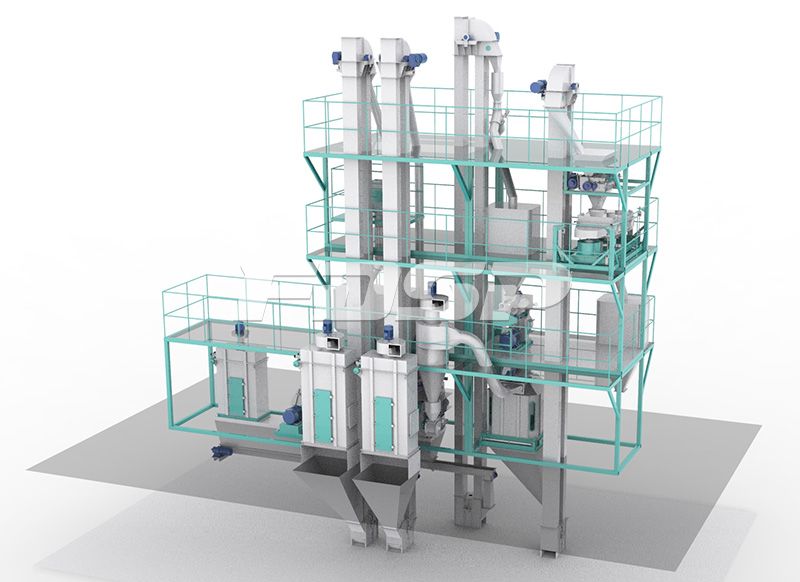

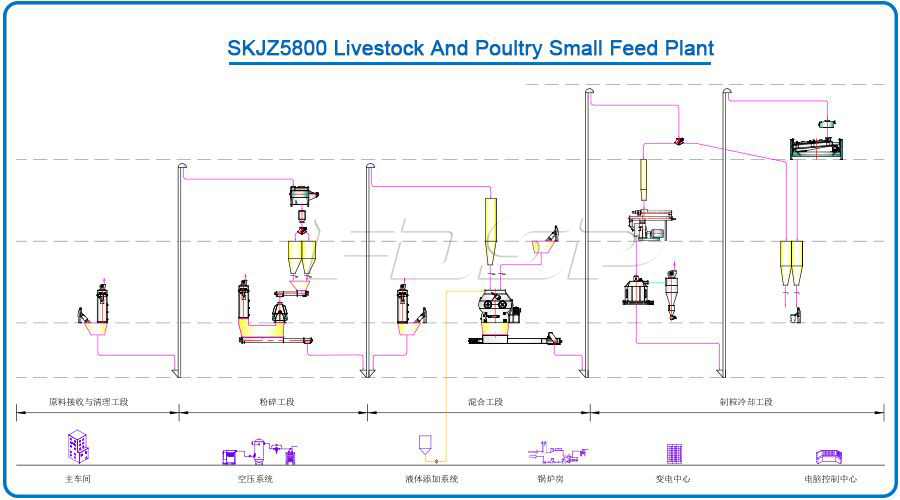

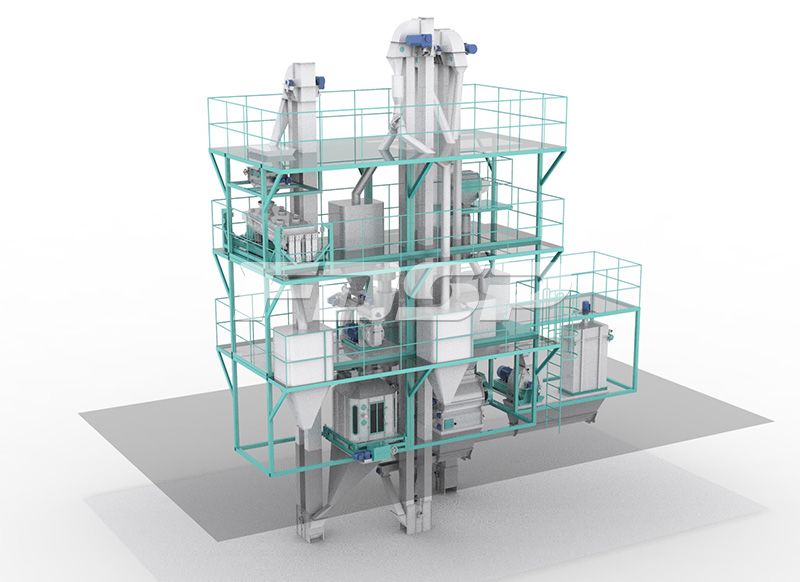

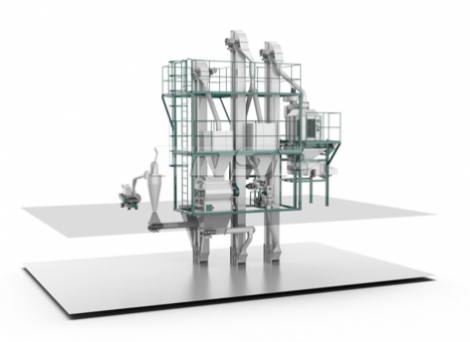

- Small Turnkey Animal Feed Production Line

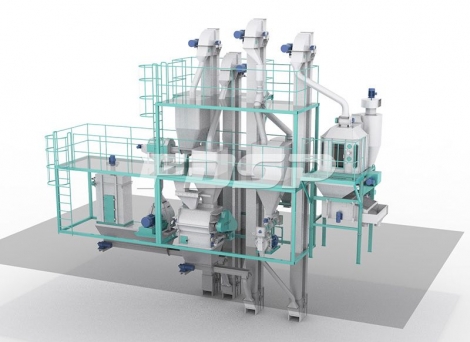

- Poultry & Livestock Feed Production Line

- Pig Feed Production Line

- Ruminant Animal Feed Production Line

- Floating Fish Feed Extruding Line

- Raw Material Extruding Production Line

- Pet feed engineering

- Premix Feed Production Line

- Concentrated Feed Production Line

- Aqua Fish Feed Production Line

- Products

- Video

- News

- About Us

- Service&Support

- Contact Us