Brief introduction of processing flow:

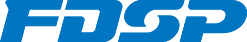

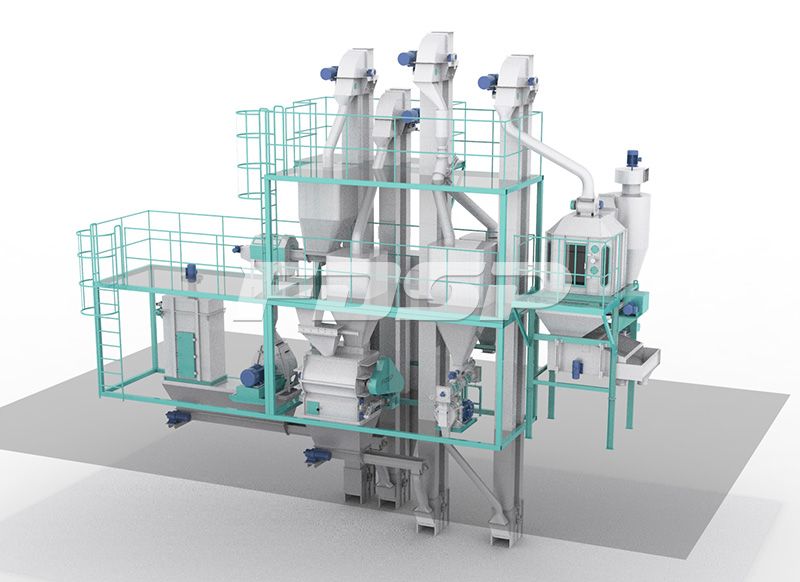

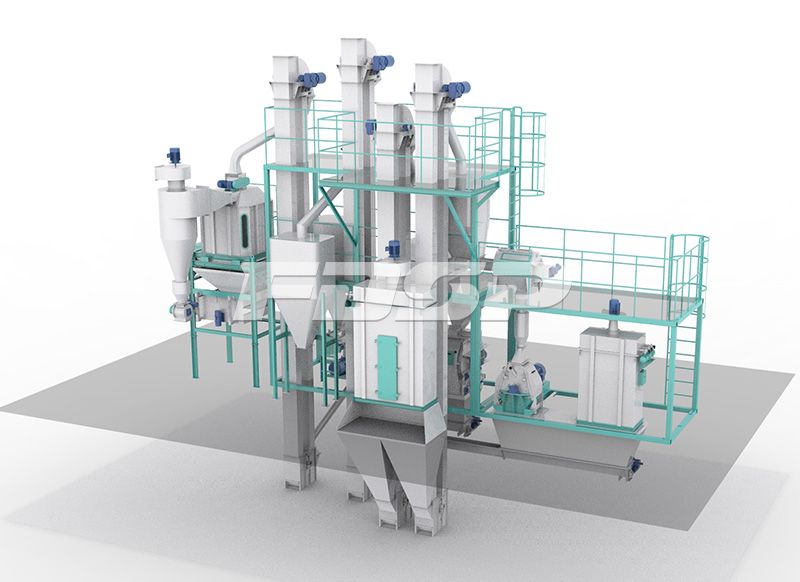

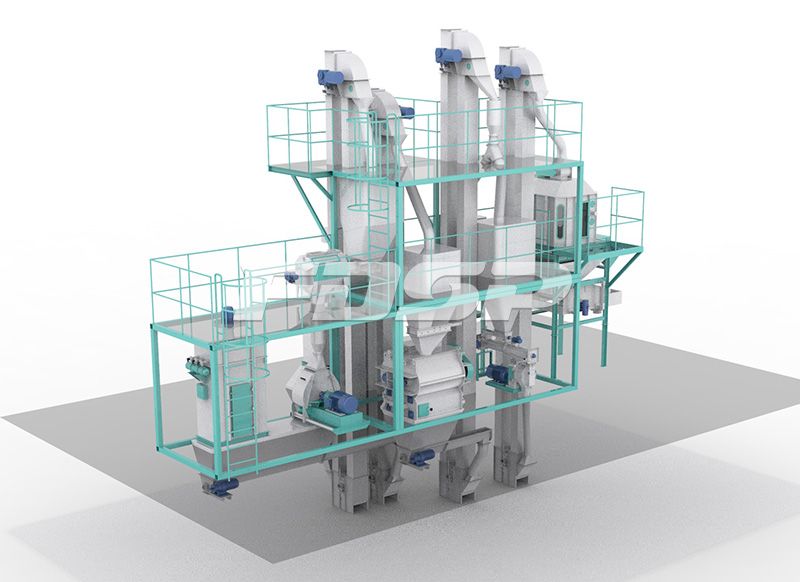

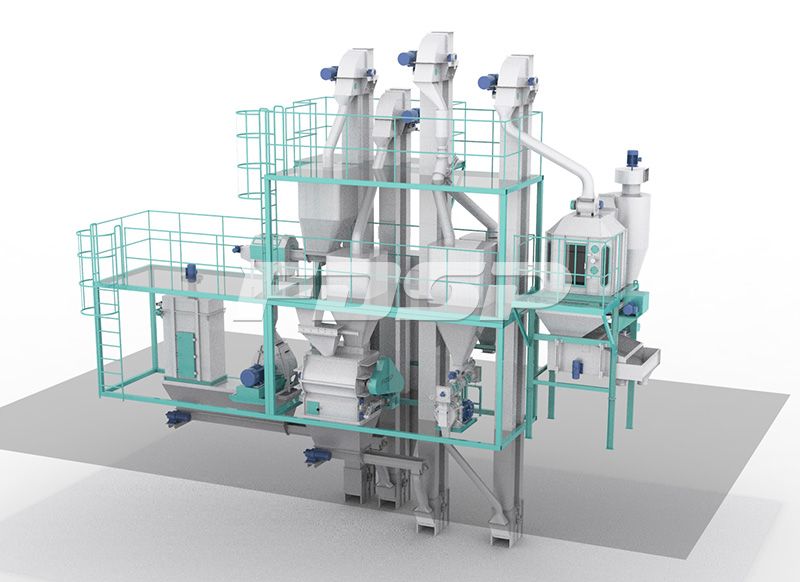

SKJZ3000 feed set takes manual way of adding raw materials. Its designed capacity is 2-3T/H for powder feed and 1-1.5T/H for pellet feed. During the processing, raw materials need weighing ahead, and then will be put into the production line from two different feeding gates. Materials which need grinding will be put into the hammer mill from pellet feeding gate by lot. Materials which don’t need grinding will be put into the line from powder feeding gate. The materials having been mixed can either be sent directly into product bin as powder feed or be sent into pelletizing process to be pelletized and cooled to be pellet feed, which need manual scaling and packing.

The total power of this feed set is about 87kw, taking an area of 12*6*8m, equipped with 0.2T boiler. The whole feed set takes joint frame that is in tight design, reasonable structure and is eco-friendly. Also, the feed set can be specially designed according to buyers needs.

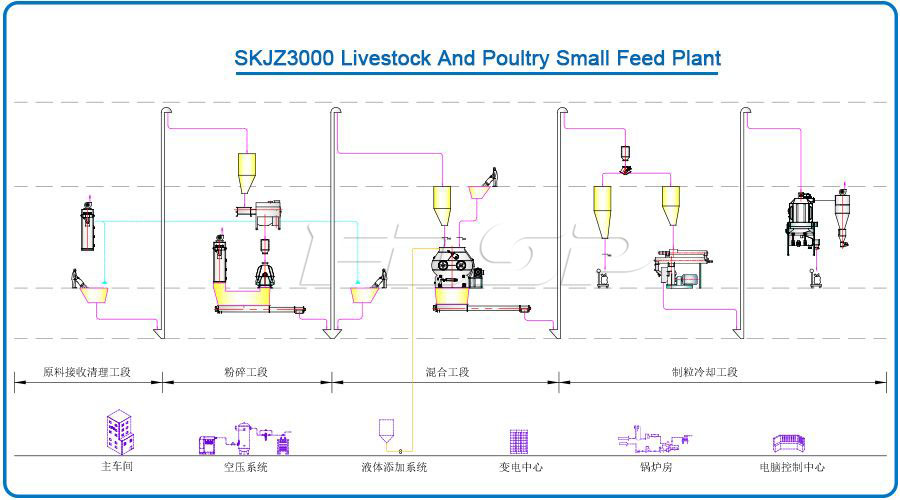

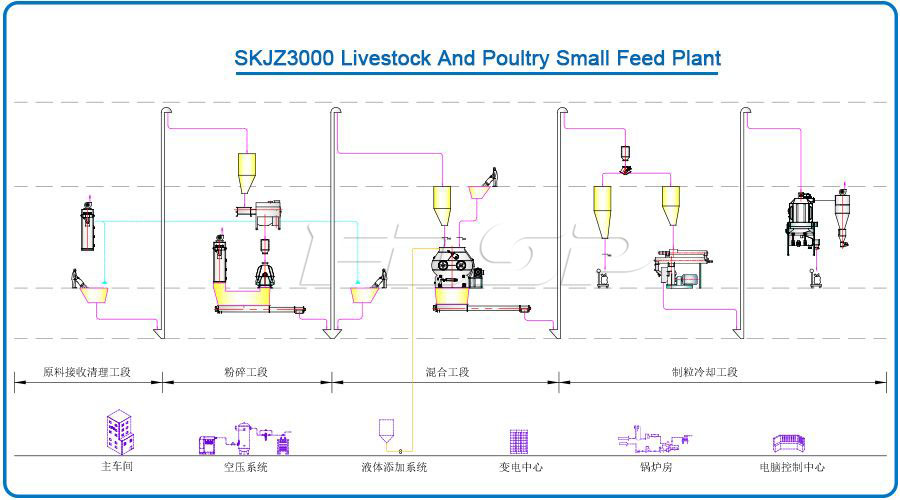

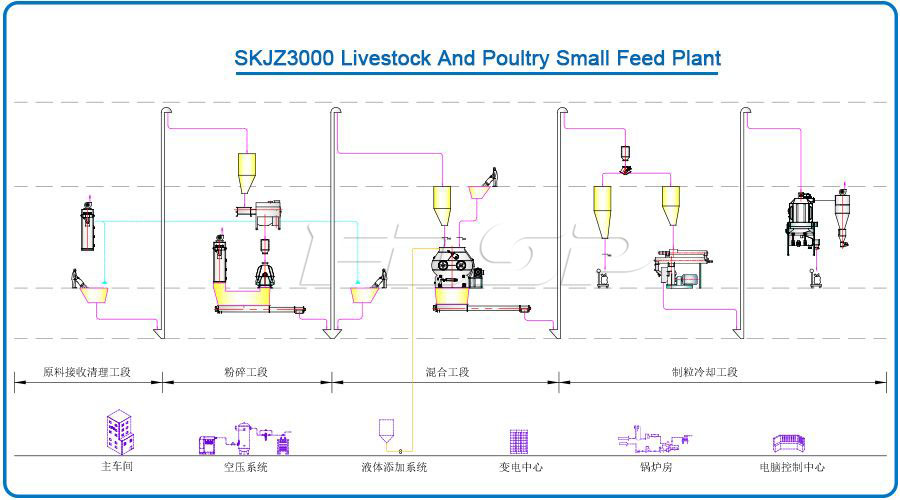

Technical Procedure:

Raw material receiving and cleaning process——Grinding process——Mixing process——Pelletizing and cooling process——Aauxiliary Process

Brief introduction of processing flow:

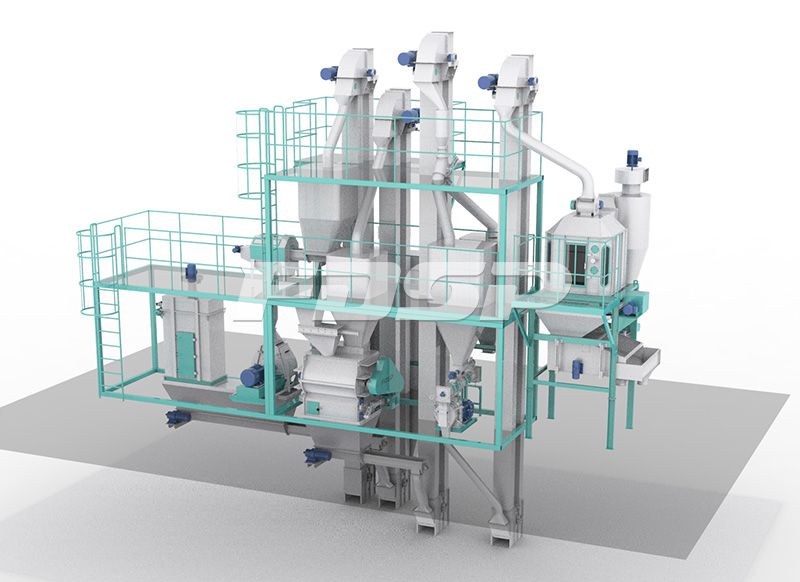

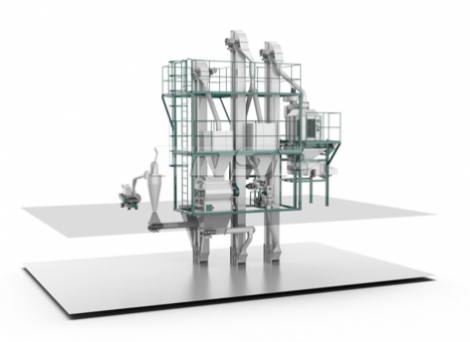

SKJZ3000 feed set takes manual way of adding raw materials. Its designed capacity is 2-3T/H for powder feed and 1-1.5T/H for pellet feed. During the processing, raw materials need weighing ahead, and then will be put into the production line from two different feeding gates. Materials which need grinding will be put into the hammer mill from pellet feeding gate by lot. Materials which don’t need grinding will be put into the line from powder feeding gate. The materials having been mixed can either be sent directly into product bin as powder feed or be sent into pelletizing process to be pelletized and cooled to be pellet feed, which need manual scaling and packing.

The total power of this feed set is about 87kw, taking an area of 12*6*8m, equipped with 0.2T boiler. The whole feed set takes joint frame that is in tight design, reasonable structure and is eco-friendly. Also, the feed set can be specially designed according to buyers needs.

Technical Procedure:

Raw material receiving and cleaning process——Grinding process——Mixing process——Pelletizing and cooling process——Aauxiliary Process