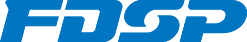

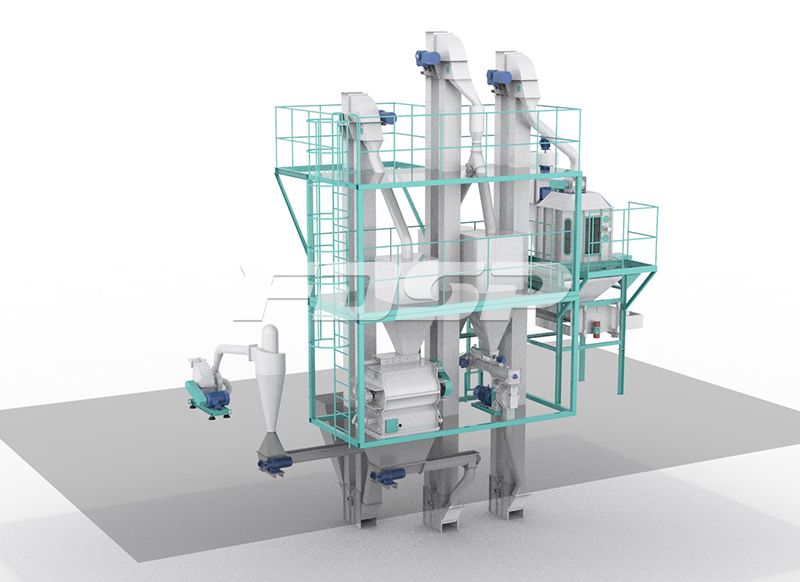

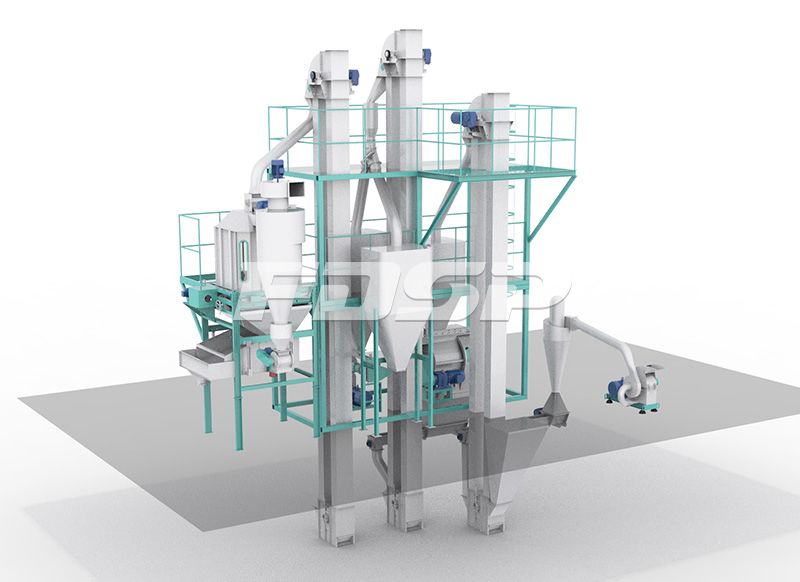

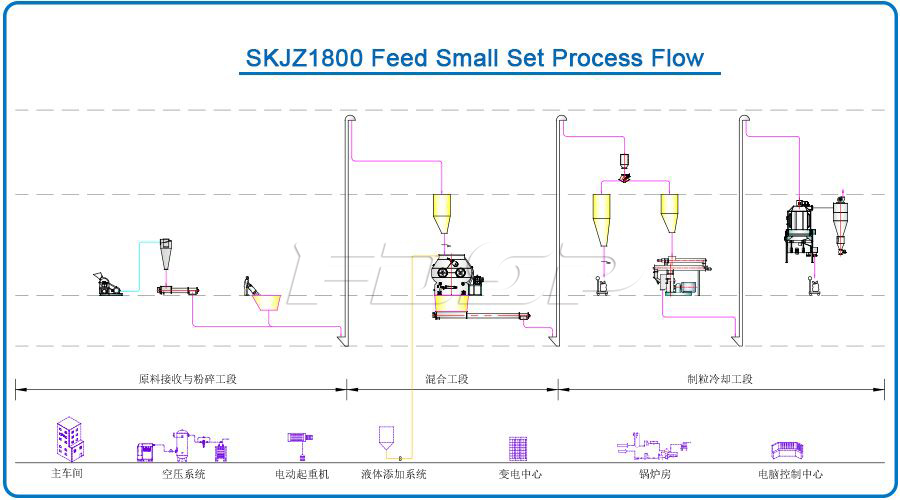

Introduction of technical features and processes

Taking integrated hammer mill, manual feeding, centrifugal output by cyclone, this technique is both easy and low-cost, suitable for multiple raw material grinding of small capacity.

Grinding machine: SFSP50, 18.5KW, designed capacity 1.5-2T/H.

-

Mixing process: Above the mixer, there is a bin for mixing that can make the production continuous. Materials having been mixed can be sent to bin for pelletizing or product bin, which satisfied the production need of both powder feed and pellet feed.

Mixing machine: Double shaft paddle mixer FHSJ0.5, 5.5KW, 250KG/LOT, designed capacity 1.5-2T/H.

-

Pelletizing process: taking a pellet with a single conditioner, it is suitable for producing ordinary poultry feed and ruminant feed; after being pelletized, the feed will be sent by elevator directly into cooling sieve and be packed manually.

Pelletizing machine: Pellet Mill SZLH25, 15KW, designed capacity 0.8-1T/H(¢3.5 ordinary chicken feed formula)

-

Cooling machine: Counter flow cooling sieve SNSZ120, designed capacity 1-2T/H.

-

Auxiliary Process: equipped with liquid adding system, oil can be added in mixer to improve the palatability of feed; equipped with air compressor, which provide compressed air for pneumatic parts of the production line.

|

The main equipment section |

|

Number |

Description and type |

Qty |

Picture |

|

1 |

Hammer Mill SFSP50 1

It is widely used for grinding for maize, grain sorghum, rice bran, rice straw, vine, maize straw, sorghum stalk, beanstalk, wheat straw etc;

Belt conveying,compact structure, easy operation, rotor passes accurate dynamic balancing test, less vibration during running;

It is with aspiration system, easy to operate;

It is suitable for rice factory, flour factory, feed factory and so on. with drive 15kw

|

1 |

|

|

2 |

Double Shaft Mixer SHSJ.0.5

Power:5.5kw

effective volume:0.5 m3

mixing capacity:250 kg/batch

mixing time:30-120 s

housing wall plate:-10/Q235

gear reducing motor: FDSP customized brand

|

1 |

|

|

3 |

Pelleting Bin 1m3

3mm/Q235 fabricated

|

1 |

|

|

Screw Feeder 0.55KW(for SZLH25) Power:0.55kw

3mm stainless steel fabricated, FC control

driving type:reducer direct connection driving

rotation speed:20-120rpm variable frequency speed adjustable

housing:-3/SUS304

screw blade:-4/SUS304

|

1 |

|

Conditioner(for SZLH25)

power:1.5KW/unit

rotation speed:175 rpm

steam pressure:≤1MPa

|

1 |

|

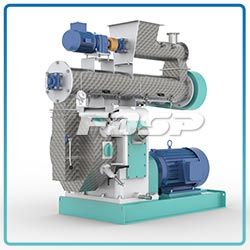

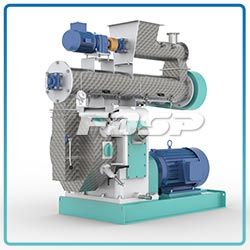

Pellet Mill SZLH25 Power:22kw

capacity:0.5-1.5T/H(¢3.5 1:10 normal broiler feed formula)

Ring die inner diameter:250mm

Working surface width of ring die:70mm

motor rotation speed:1460 rpm

process to ensure the stable driving and low noisy of gear

screw feeder, conditioner, feeding chute all made by stainless stee

|

1 |

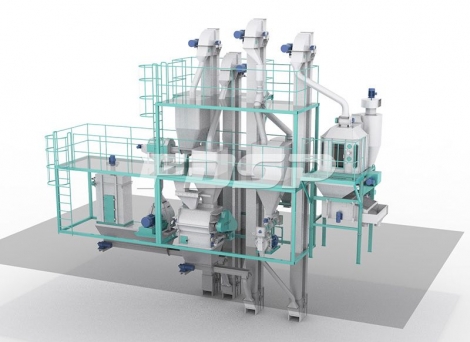

According to individual needs of different buyers, the solution can be optimized:

1. There need to be an air compressor system for valve, discharging gate, etc. Those pneumatic parts can be changed into electric valve and electric discharging gate in order to save the investment of air compressor system.

2. Give the low capacity; the feed set isn’t equipped with raw material cleaning system and take manual pre-cleaning instead. If buyers need, the raw material cleaning system can be added.

3. In the set, there are product bins for both powder feed and pellet feed. If the powder product isn’t expected, the product bin for powder can be cancelled.