The development of feed technology in the new era mainly focuses on the following aspects:

1. Improve the production efficiency of stand-alone equipment and reduce costs;

2. Promote the diversification of equipment and process functions;

3. Research and develop new products and new processes with more powerful functions;

4. Promote production to be safer, more reliable, and simple and humanized in later maintenance;

5. Improve the level of automation and realize effective control.

In the future, the feed industry will take the next few points as the themes for technology research and development and process improvement.

1. Development of new fidelity technology and equipment for feed processing

Thermal processing technology can effectively kill harmful substances and improve the palatability of feed, but it also destroys many beneficial ingredients, such as vitamins and enzyme preparations. In order to solve this problem, we generally adopt two fidelity processing technologies:

1) Reduce the loss of activity by "coating" or "microencapsulating" heat-sensitive components;

2) Add liquid heat-sensitive components after conditioning, granulation or puffing to achieve the fidelity of the active ingredients.

2. Continuous ingredients and mixed feed processing technology

Nowadays, due to the backward batching system, the mixer cannot fully play its role of high efficiency and high quality. If the continuous batching and mixing process can be realized, it will undoubtedly greatly improve the production efficiency of the feed factory, and at the same time will reduce the labor expenditure, reduce the investment cost, and realize the cost reduction and efficiency increase.

The continuous batching and mixed feed processing technology is an online measurement equipment researched and developed using modern testing technology, which can measure multiple raw materials online at the same time, and can be adjusted according to the distribution ratio and the characteristics of the raw materials.

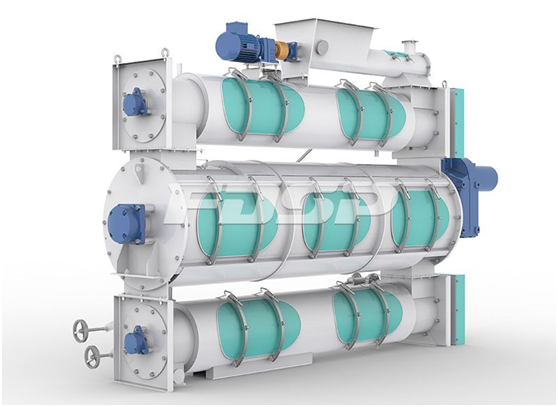

3. Feed steam conditioning technology

How to improve the stability of pellet feed in water without adding a binder has become an urgent problem. Some foreign feed factories use a three-layer steam conditioner on the pellet mill, which can make the pellet feed water stable for more than 10 hours, and the pellet surface is smooth and the texture is good.

With the rapid development of feed aquaculture, three conditioning methods have emerged one after another;

1) Multi-stage tempering: the effect of tempering can be improved by extending the tempering time, the starch gelatinization degree can reach 40%~60%

2) Maturation and conditioning after granulation: heat the freshly pressed granules (about 70~80℃), let the hot granules last for a period of time in a high temperature and high humidity environment, so that the starch in the granular feed is fully gelatinized and protein It is fully denatured, and at the same time, the cracks produced in the early stage are glued again, and the durability of the feed is improved to meet the special requirements of aquatic feed.

3) High-pressure annulus expansion and conditioning: A new method of conditioning and conditioning for powdered feed. The material is intensively squeezed and pressurized with steam in the work area to make the solid, liquid, and gas three-phase materials in the whole Under the combined action of shearing force, squeezing force and steam pressure, it is forced to push through the conical discharge valve with adjustable annular gap. The whole process only takes a few seconds, but the high pressure can reach 10MPa and the material temperature can reach 170℃. So that the material can be fully tempered and matured.

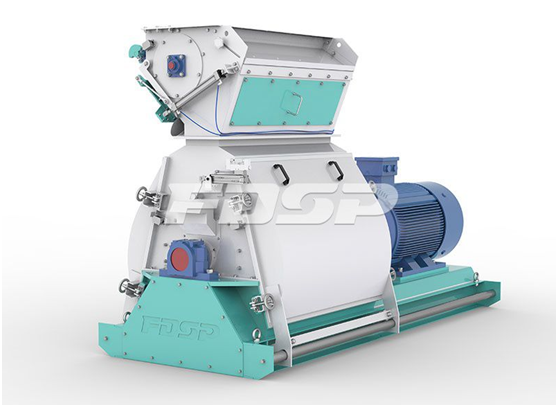

Four, crushing processing

The crushing process mainly studies crushing particle size, uniformity, power consumption and the fields related to crushing. There are mainly three types of crushing equipment: horizontal hammer crusher, roller crusher and vertical hammer crusher. Among them, the roller crusher has a relatively uniform crushing particle size and can control the distribution range of the particle size.

Different feed types and different feeding objects have different requirements in feed production, so it has become a development trend to use them in combination according to needs. There are currently three types of crushing processes, namely primary, secondary and closed-circuit crushing processes. Compared with the primary crushing process, the secondary and closed-circuit crushing process has low energy consumption and is easy to improve productivity and product quality. Therefore, it is mostly adopted by large and medium-sized feed mills.

Five, batching process

The changes in the batching system are mainly to adapt to the increase in the added variety, the decrease in the added amount, and the improvement of weighing accuracy. At the same time, it is necessary to shorten the weighing cycle and increase the production per unit time.

Online formulation is one of the areas to be developed. An instrument is currently being tested, installed on the ongoing equipment, to perform online analysis of the chemical composition of the raw materials to be used. Therefore, it will be possible to reorganize the feed formula batch by batch, make the required feed very accurately, stabilize the feed quality, and reduce the impact of the change of raw materials on the feed quality.

Weighing accuracy is another area of development. The dosing system needs to be improved in the accuracy of weighing and the time of weighing. There are several micro-dosing systems, which are measured by weight reduction. The weight reduction method can avoid the appearance of air volume and improve the accuracy of weighing. At the same time, it is possible to weigh 10 or more materials. This shortens the batching cycle, and the accuracy is relatively high, and the cycle time is very short. To match the mixer.

6. Develop feed processing machinery that meets rural needs

China's rural areas are vast and rich in resources, and the development of machinery and equipment suitable for rural feed processing is in line with the development prospects. Such as straw feed processing machinery, which processes waste straw into feed for waste utilization; such as leaf protein extraction machinery, which solves the problem of industrial extraction of leaf protein from different raw materials (such as green manure, pasture, leaves, etc.); such as 1 ton per hour feed pellet equipment , Quick return on investment province, suitable for use by townships and self-employed.

Seven, continuous improvement of automatic control

Judging from the current status of feed mills, production process control automation and computer production management have not yet played their due role in improving product quality and variety. To this end, the State Grain Reserve Bureau proposed the use of computer technology for quality management and production dynamic quality monitoring, and developed a feed production quality dynamic monitoring system, so that a large number of quality-related data existing in the production process can be effectively collected, stored, and evaluated And control, and produce a series of control loops to solve the quality problems in the production process, so that the processing process can reach a good production state.