I. Safe operation rules for pulse filter

1. It is forbidden to start the fan of the air shutter when the air shutter (including the unloading spiral of some dust precipitators) is not started or the air shutter is blocked. If the air shutter fails to discharge the material normally, it will cause dust accumulation in the dust hopper of the dust collector and affect the normal work of the dust collector.

2. It is strictly forbidden to dig and drain the material in the air blower during the operation of the dust collector.

II. Operation and maintenance procedures

1. During the operation, check whether the pulse valve is blocked and leaking or not at least once per shift, whether the compressed air injection is normal or not, and discharge the water in the oil and water separator triplet once per shift.

2. Check the connection of fan and dust collector once per shift for leakage.A thin string can be used around the connection to detect, if the thin line is sucked, it indicates a leakage point.

3. Once a week, no load is sprayed to blow cloth bags for 5 minutes. If the pulse controller and fan power are separated, the spraying shall continue for about 1 minute after each shutdown.Make sure the cloth bag is not too thick with dust.

4. Open the maintenance door of the dust collector once a month, check whether the cloth bag is damaged, and clean the dust on the surface of the cloth bag. Slight damage of the cloth bag can be repaired by means of binding and sewing.Cloth bag cleaning can only be knocked, not washed with water;If the cloth bag is wet, it should be dried after rubbing, beating, to clean up the dirt on the surface.

III. Maintenance procedures

Minor repair (once every half a year)

1. Check whether the wiring in the motor junction box is loose.

2. Check the wear condition of pulse solenoid valve and seat, and replace the worn solenoid valve diaphragm.

3. Clean the dust accumulated in the inner wall of the dust collector and the dust bucket.

4. Clean oil and water separation triplets to ensure smooth air passage.

Medium repairs (once a year)

1. Minor repair’s all contents.

2. Clean the fan blades, check the wear of the fan blades, and check the balance of the fan blades when necessary.

3. Disassemble and check the wear condition of the fan impeller, and replace the worn parts.

4. Clean the inside of the unloading screw, check the wear of the screw blade, and repair or replace it if necessary.

5. Disassemble and wash the reducer, check the wear condition, and replace the lubricating oil for the reducer.

6. Check the wear condition of each bearing and replace the bearing with severe wear.

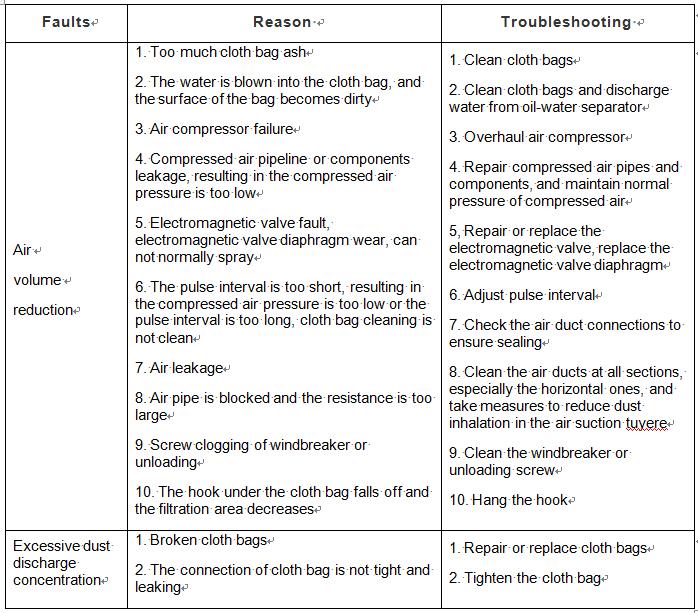

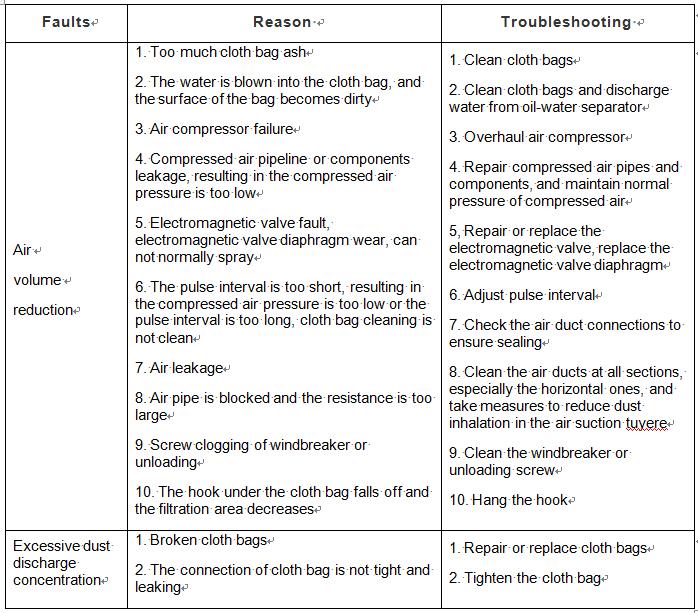

IV. Common faults and troubleshooting methods