First, Safety Operation Procedures

1. Turn off the power and hang up the warning sign When inspecting, repairing and maintaining the machine.

2. Allowed to open the observation door after the machine completely stopped,

3. Apply a tracheal blow not hard objects or hands when cleaning the materials in the machine

4. Motor cables and wires should have protective sleeves.

Second, Maintenance Procedures

1. Always keep the cooler surface and inner wall clean.

2. After shutdown, Clean up the remaining materials to avoid cross-contamination or particle adhesion on the inner wall of the machine.

3. Add grease to the air locker every month. The lubricant uses 2# lithium grease.

4. Clean the reducer once a year and replace the oil.

5. lubricate the other bearings of the machine once every six months.

Third, Repair Procedures

Minor repair: once a time every six months, including:

1. Remove residue from the cooler.

2. Adjust and test the sensitivity of the leveler.

3. Check the operation of the discharge fence bearing, and replace it when wear is serious.

4. Remove and wash the transmission bearings and add lubricant.

Intermediate repair: once a time per year, including:

1. All content of Minor repairs .

2. Check that the discharge device is working properly and replace the damaged parts.

3. Check the airlock bearing and replace the grease.

4. Check the operation of the gear unit and replace the grease.

5. Repair and replace the eccentric bushing with severe wear.

6. Check the wear of the air blower impeller, and replace or repair it when it affects the closed air effect.

7. Check the sealing of the sealing window and replace the deformed viewing window.

8. Replace damaged wires and signal wires.

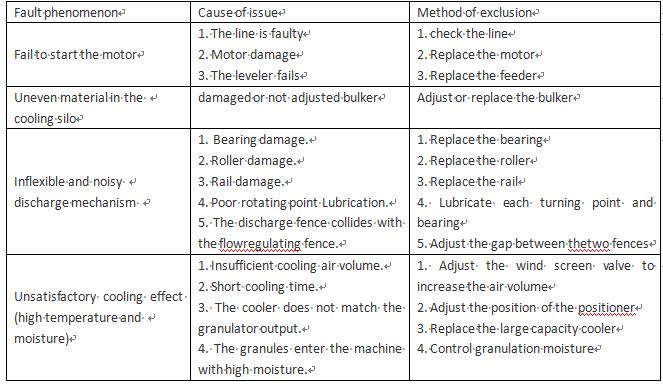

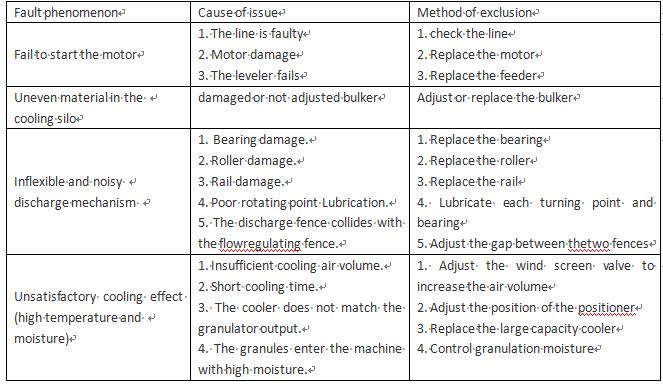

Fourth, Common Faults and Troubleshooting Methods