Conditioning is a process of hydrothermal treatment of powdered materials before pelleting, and it is also one of the important factors affecting the quality of pellets. With the improvement of the market's requirements for pellet feed quality, feed processing companies are paying more and more attention to the conditioning process in feed processing. Improving and upgrading conditioning equipment is one of the important means to improve the quality of pellet feed products and increase market competitiveness.

1. The role of conditioner in pellet feed processing

1. The powdery materials are cured. The ability of most animals to digest starch is very low, but they can digest cooked starch to a greater extent. The conditioner greatly increases the gelatinization degree of the starch under the action of water and heat, and also promotes the heat denaturation of the protein in the material. The denatured protein is easy to be hydrolyzed by enzymes, thereby improving the digestibility and utilization of pellet feed.

2. Sterilize powdered materials. Most of the pathogenic bacteria, such as E. coli and Salmonella, are not heat-resistant. Using a conditioner to condition the material at a certain temperature can kill these bacteria and ensure the hygiene level of the feed.

3. The conditioning equipment can significantly improve the water resistance of pellet feed. In the conditioning process, through the hydrothermal effect of steam, the viscous components in the material gelatinize starch and denatured protein can fully play the role of the binder, which can be effective Bonding with other surrounding components, under the squeezing action of the compression molding roller, the particles and the particles are more closely combined with each other, so that the pellet feed becomes more dense, the appearance is smooth, and it is not easy to be corroded by water during the feeding process. Increased stability in water.

4. The quenching and tempering equipment can improve the granulation of the material, increase the output, save the energy consumption of granulation, and increase the life of the die and pressure roller of the granulator. Through quenching and tempering, the material can be softened and made more plastic. During the extrusion process with the die hole wall, the inner wall of the die and the surface of the press roller, the friction force is reduced, which avoids the transformation of a large amount of mechanical energy into heat energy during the pelletizing process. At the same time, the abrasion of the pressure mold and the pressure roller is slowed down.

Second, the correct choice of conditioner for feed mills

Ordinary livestock and poultry feed factories can choose a single-shaft paddle-leaf conditioner to ensure a conditioning time of about 30 seconds. The starch gelatinization degree can reach about 20%, which basically meets the processing requirements of ordinary livestock and poultry feed; aquatic feed The factory should use two-stage and three-stage conditioners or double-shaft differential paddle-type conditioners to ensure that the maturation of the conditioned feed reaches more than 50%.

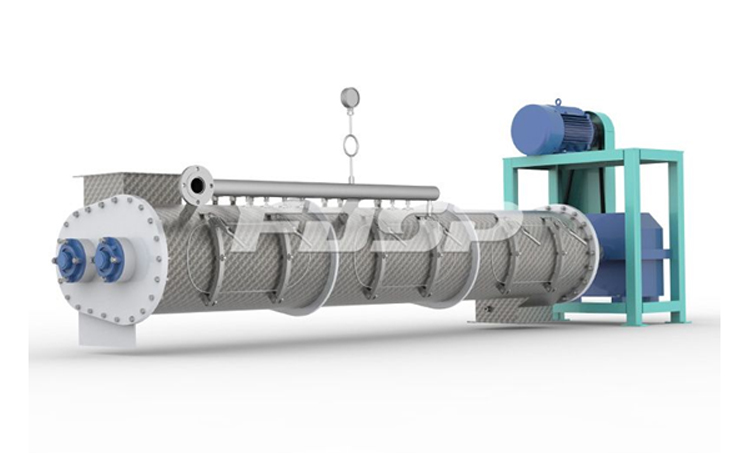

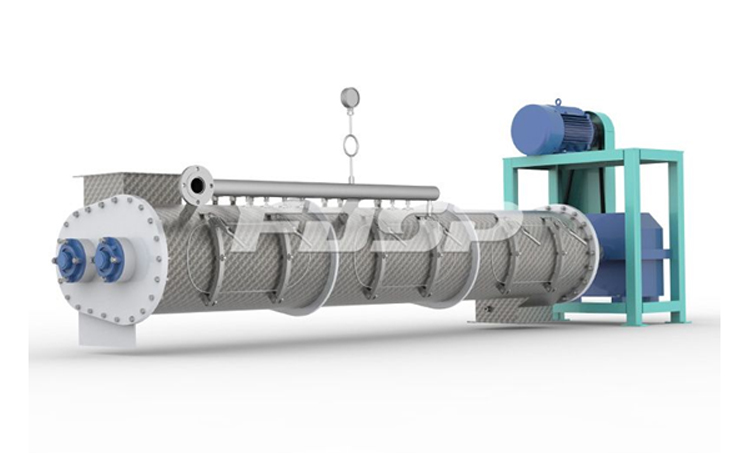

▲Liangyou STZS series dual-axis differential conditioner

■ Long tempering time, high maturation, low noise, high output and low energy consumption.

■ In addition to adding steam to the material, it can also add multiple liquids to the material at the same time.