Processing requirements for different materials in the production of extruded materials:

Under normal circumstances, the various raw materials used for extruded feed are crushed as finely as possible. Strict aquaculture farmers pass 80 mesh (aperture of 0.18 mm) sieve ultrafine crushing to meet their fineness requirements. The finer the particles of the raw materials, the higher the digestibility, pelleting fastness and water stability; in addition, the feed additives should be pre-mixed to make a 4% -5% mixture, and then mixed into the feed. In order to maintain a certain degree of uniformity.

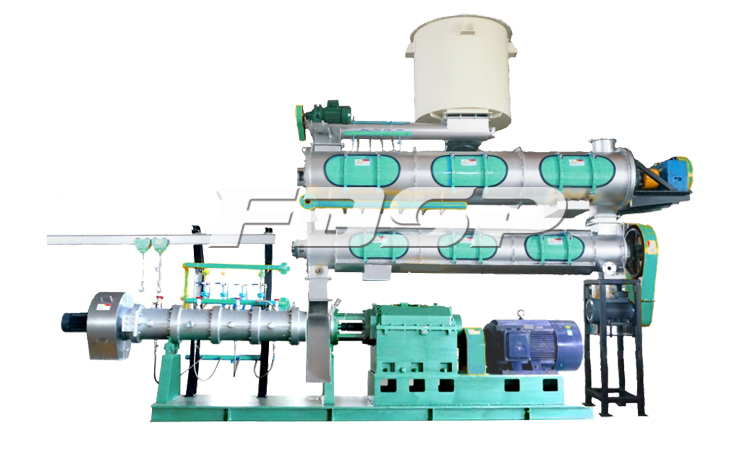

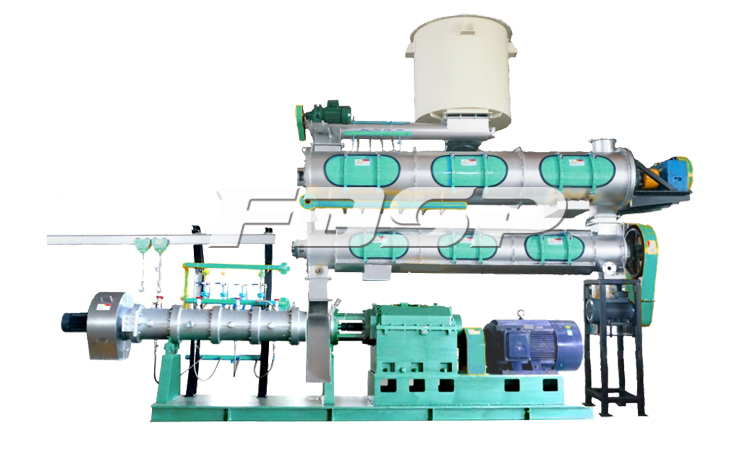

Extruded material production process:

Some heat-sensitive vitamins should be added to the puffed powder. First, add steam or water at about 100℃ to the powder to make the water content reach 25%, and then pass the hot powder through the drum of the puffing machine to increase the temperature. At about 140°C and 6 kg/㎡ pressure, it is sent to the compression molding device, and then the pressure drops rapidly. The super hot water evaporates and causes the particles to expand (granulation). After the expansion, the grease is immediately sprayed on the surface of the particles to ensure The granulating surface is smooth. At this time, the pellet feed is once again sent to the heated channel to evaporate, reducing its water content to below 10%, and finally it is cooled to room temperature to form an extruded pellet feed.

The mineral pre-powder can be added before the raw materials are crushed, while the vitamin pre-powder should be added when the raw materials are crushed and mixed. The purpose of this is to reduce the loss of vitamins during processing and heating. The particle size should generally be 1-2 mm, easy for fish and shrimp to eat, otherwise, it will cause waste due to poor palatability of the feed.

Jiangsu Liangyou Chia Tai Co., Ltd. (FDSP) has a wealth of experience in the construction of feed plants and the transformation of old plants, and can provide you with more professional guidance. For details, please inquire