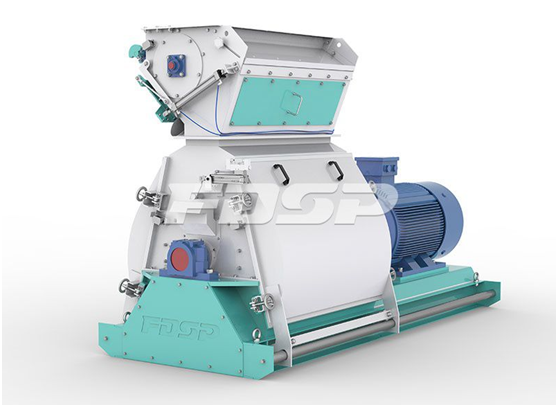

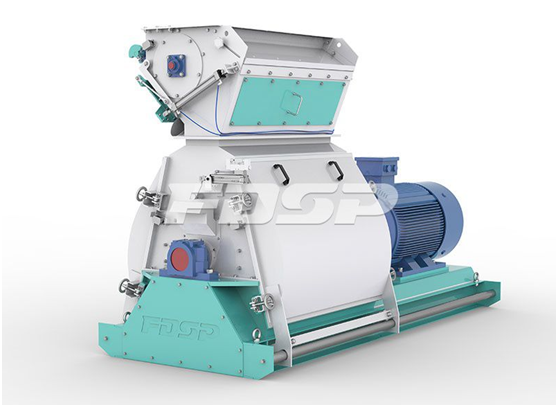

Hammer mill is an extremely widely used crushing machine, especially in small and medium-sized feed mills, it is very suitable for material crushing in feed mills.

The performance requirements of the pulverizer in feed production: 1) The pulverization quality and particle size need to be uniform; 2) High efficiency and low energy consumption; 3) Good sealing performance, reducing leakage; 4) Simple structure and convenient maintenance; 5) Less dust and noise Small.

Hammer mills meet the above requirements and are widely used. The following introduces the selection, installation and use of hammer mills.

1. According to the output, choose the feed suitable for the production of different animals, and the required crushing particle size is different. The livestock and poultry feed is millimeter and micron, and the fish and shrimp feed is micron. If the production capacity of the pulverizer is too small, it will cause long-term production every day, which is not good for the equipment itself. If the model is too large, it will cause excess production, cause storage pressure, and there is a risk of feed mildew.

Second, the installation of hammer mill

1. When the pulverizer is used for a long time, the pulverizing frame should be installed on the cement foundation, or the pulverizer can be fixed on the frame for use alone.

2. All equipment and lines must be installed correctly and reliably.

3. After installation, all rotating parts should run flexibly, and run dry for half an hour to check if there are abnormal sounds.

4. Check whether there are hard substances such as sand and iron in the raw materials, so as not to damage the machine.

Third, the use of hammer mill

1. Start the pulverizer and let it idle for 2-3 minutes, observe the operation, and then start the operation after confirming that it is correct.

2. Always pay attention to the operation of the pulverizer during work. If there is any abnormality, it should be stopped and checked, and then work after troubleshooting.

3. It is strictly forbidden to open the machine door when the pulverizer is running. The transmission belt drive should be equipped with protective devices. It is strictly forbidden to work with overload for a long time. Smoking is prohibited in the workplace.

4. After the work is finished, run the machine for 2-3 minutes to completely remove the materials in the machine.

5. Before shutting down, crush all the blocks in the crushing chamber to avoid difficulty in starting the machine next time. If the accessories are found to be worn or damaged, they should be repaired in time, especially the hammers and screens.