Pulverization is an inevitable problem in feed processing. High pulverization rate will not only affect the pellet quality, but also increase the cost of feed mill. We can carry on the effective control through the following aspects.

Raw material formulation

The formula of different kinds of feed is different, and the difficulty of pelleting is also different. Controlling the moisture content of raw materials as far as possible before processing is helpful to increase the amount of steam added, increase the viscosity of raw materials and reduce pulverization. It is necessary to add binder in the formula to improve the briquetting degree. In the oil and fat adding section, the amount of addition should not exceed 5% , too high will also be detrimental to the formation of pulverization phenomenon.

Processing aspect

Grinding: for different types of particles, to choose the appropriate size of grinding. The finer the material after grinding, the better the adhesion, the lower the pulverization rate, but too small will increase the energy consumption and reduce the efficiency. Therefore, the cost and the characteristics of raw materials should be comprehensively analyzed to select the most suitable crushing size.

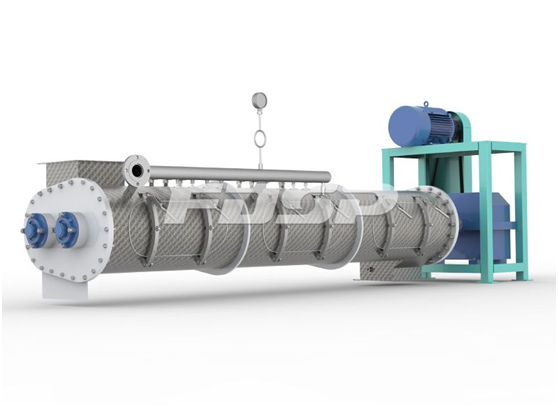

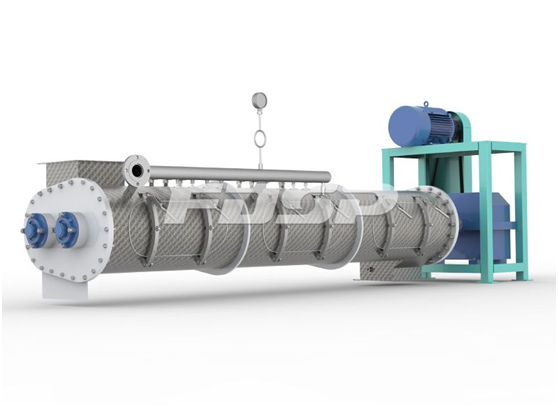

Conditioning: conditioning is the key link. Conditioning moisture, temperature, steam, time and so will determine the conditioning effect. Too high or too low will have a large impact on the quality of particles. Conditioning can make starch gelatinize, change the structure of cellulose and protein, increase the cohesiveness of feed, improve the particle density, is the key to effectively reduce the rate of pulverization. The starch can be fully gelatinized by prolonging the conditioning time and increasing the temperature to increase the viscosity and reduce the rate of pulverization.

Granulating: choose appropriate granulator according to different raw materials, configure different specifications of ring die, as far as possible choose high compression ratio ring die, to ensure the compaction of particles, enhance the hardness and density of particles. Such as the fish feed can be selected 12 ~ 11:1, livestock and poultry pellets can be selected 10:1 compression ratio.

Cooling: in the cooling section, choose a scientific cooler, cooling speed should not be too fast, uniform cooling, in order to prevent particle cracking, leading to increased pulverization rate. The FDSP counter-flow cooler is adopted, the cooling process is soft and uniform, and the cracking phenomenon is effectively solved.

Screening: the production capacity of the screener must be greater than the granulation capacity, otherwise it will lead to incomplete screening, so as to improve the pulverization rate of the finished product.

To reduce the rate of pulverization and improve the overall quality of feed, it is fundamentally necessary to control the process. FDSP will conduct directional process design according to the different raw materials of different customers, with scientific and reasonable integrated system scheme to provide customers with stable and reliable feed engineering construction.