As an important part of the whole production line, the screening efficiency of the vibrating screen directly affects the overall productivity and production quality.

What conditions affect the screening efficiency?

1. The screen is deformed, the material is retained, and the uniform screening force is reduced, resulting in low screening efficiency;

2. The screen is broken, which makes the material that should not pass through the screen pass through, affecting the screening effect.

What factors will cause screen deformation?

After the vibrating screen is tensioned, it mainly bears the tension at both ends of the screen between the cross braces and the uniformly distributed load in the middle. The local stress concentration of the screen is serious, which will cause the screen deformation and affect the screening effect.

How to improve the flatness of the screen?

1. Increase tension:

Timely check the tightness of the screen, re-tension the nails or replace the screen.

It should be noted that within a certain range of prestress, it has obvious effect on improving its flatness, but too large adjustment of tension will cause the stress in the screen to increase. The adjustment shall be carried out within the safe allowable value according to the material characteristics of the screen itself.

2.Reduce the spacing of cross braces

An appropriate number of cross bracing beams is one of the necessary conditions to ensure the smoothness of the screen. By increasing the number of cross braces to reduce the cross brace spacing, the maximum stress value of the screen is reduced, and the overall stress distribution of the screen is more uniform.

It should be noted that too many cross braces will reduce the screening area. When the number of cross braces reaches a certain value, the flatness of the screen will also reach the bottleneck. It is of little significance to continue to increase the cross braces. With the increase of the number of cross braces, the screening area will also decrease. Therefore, the balance between the number of cross braces, screen material, load distribution and screen area should be comprehensively considered in the adjustment.

What factors can cause screen breakage?

1.Long-term local concentrated stress

Timely repair and adjust the stress: tension, pressure, shear stress, and try to ensure the uniform stress of the screen.

2. resonance

When the vibration machinery is running, when the motion frequency is close to the natural frequency, it will produce resonance. At this time, some parts of the equipment will produce abnormal and violent vibration. If the resonance is not eliminated in time, it will cause damage to parts and screen breakage.

The resonance can be eliminated by reinforcing the frame or steel platform to avoid the resonance point.

3.Fixation of screen frame

The screen frame of the vibrating screen must be fixed in the screen body and run synchronously with the equipment. If the screen frame clamping mechanism fails, it will cause the screen frame and screen body to move out of synchronization, and abnormal noise, uneven material distribution, and excessive vibration at the middle or end of the screen frame will occur during operation, which will cause the screen mesh to break and parts to be damaged.

Regularly check the screen frame clamping mechanism, and tighten it in time if it is loose, so that the screen frame can be effectively fixed.

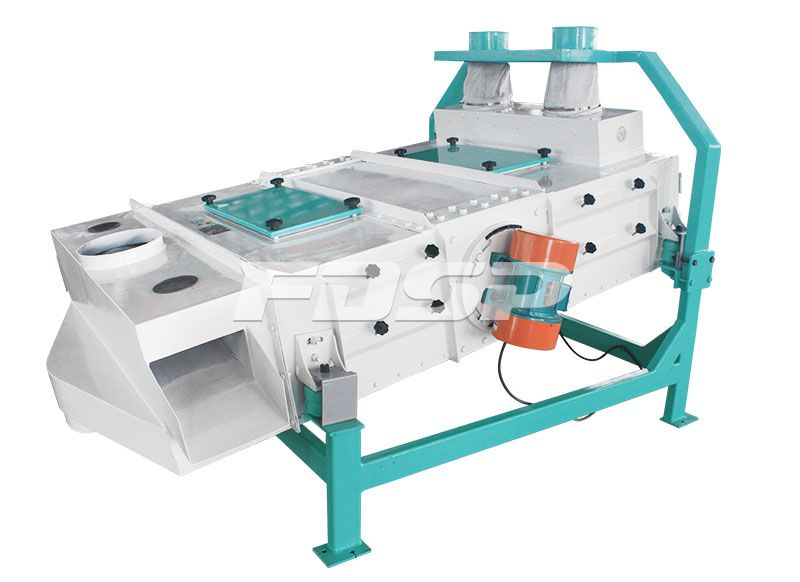

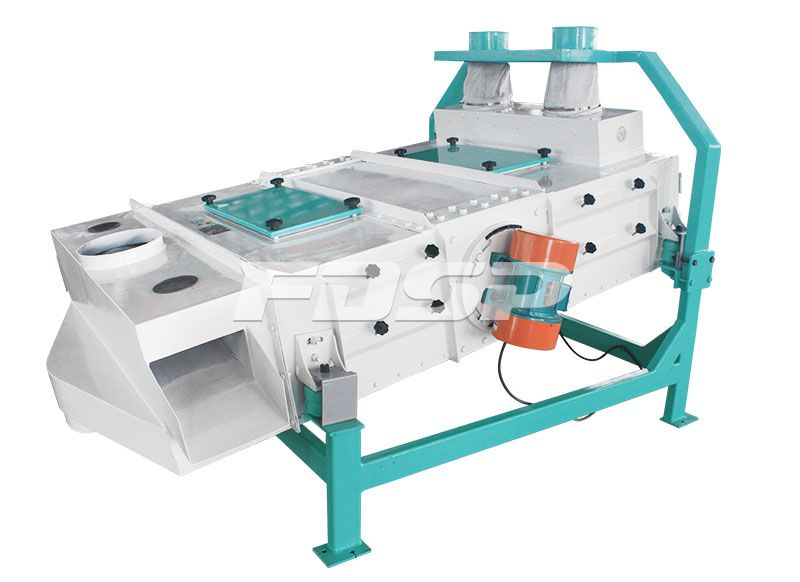

FDSP vibrating cleaning screen is mainly applicable to the cleaning of large impurities, powder impurities, light impurities and other impurities in wheat, rice and other grains. Large output, high efficiency, low power consumption, good cleaning effect, stable operation and low noise; Adopt integral frame type to effectively solve the problem of cracking and welding of screen body; The inclination angle of screen surface can be adjusted within 0-12 °; The upper and lower double-layer screens are used, and the three-layer screen vibrating screen can be customized; Screen replacement is convenient and fast.