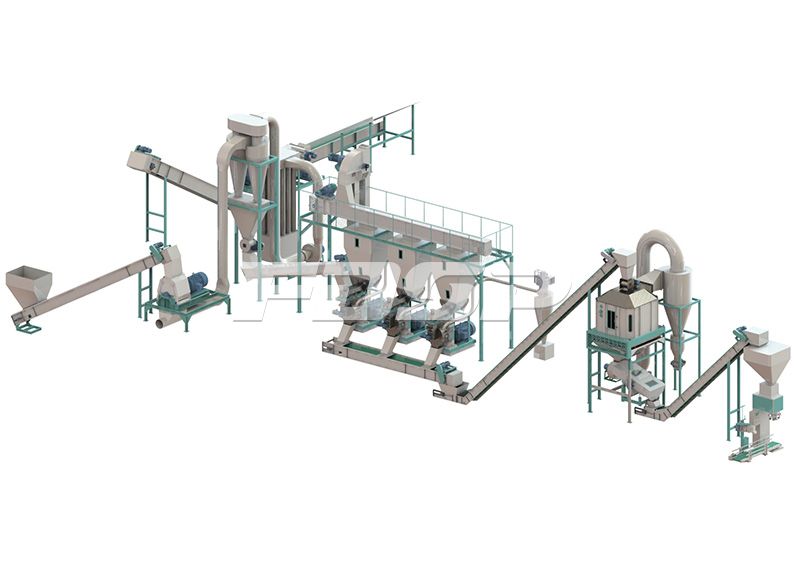

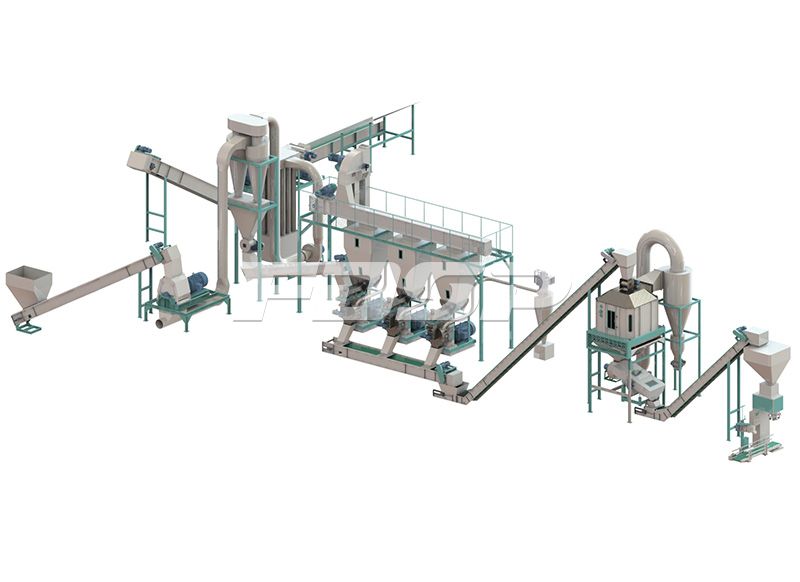

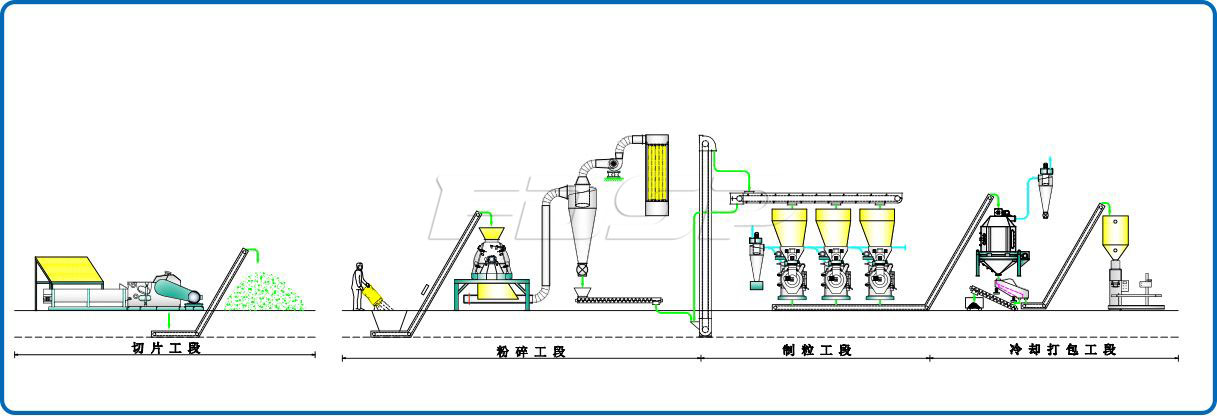

The process is as follows

chipping process

In the chipping process of leftover material pellet production project, leftover material are chipped into wood chips with 20-30mm dimension and 3mm thickness then go to following process. The feeding system of chipper consists of feeding part and press part, automatic control hydraulic system are adopt in press part, the material going smoothly in feeding system, material could be returned when overloaded to prevent blockage.

Chipper: LYGX216,main power 55kw,feeding roller power 3kw, oil pump power 0.55kw, capacity 10m3/h

Grinding process

The grinding process of leftover material pellet production project consists of more than one auxiliary equipment such as cyclone, bag filter, and the grinding work has no dust discharge. After grinding, the sawdust will be transported through pneumatic transmission by the fan suction air pressure. The output sawdust is generally about 3-4 mm. The hammer mill is a water droplet type structure with high grinding efficiency; the hammer mill rotor can be operated in forward and reverse directions to improve the service life of the hammer blade; the direct transmission mode of the motor is adopted, the transmission efficiency is high, and the maintenance is convenient.

Hammer mill: MFSP68*80,power 90kw,capacity: 3-4T/H

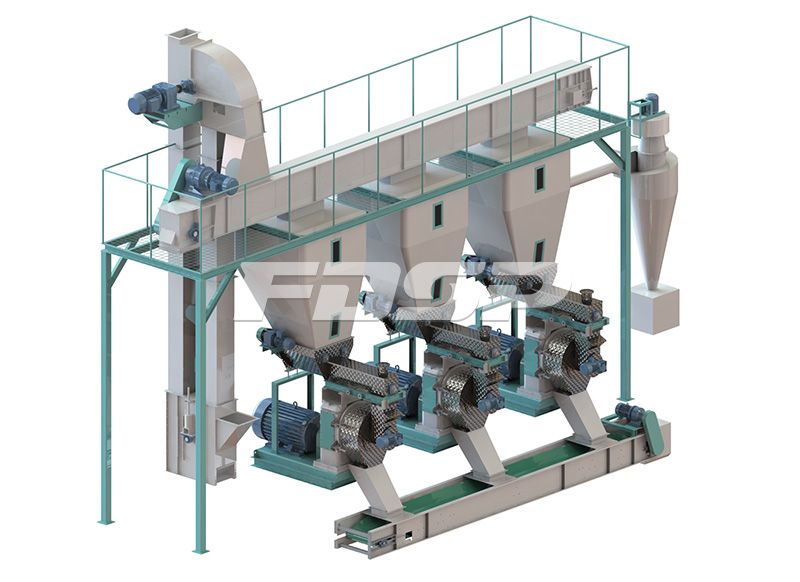

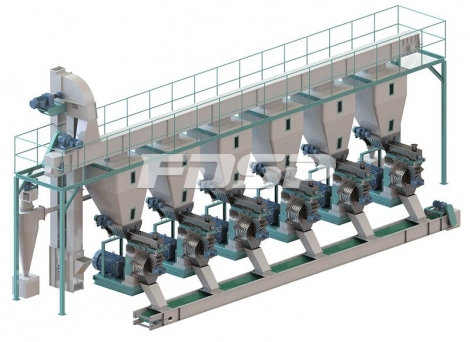

Pelleting process

Three sets of MZLH420 biomass pellet mill were designed in the pelleting process. The diameter of biomass pellet is optional from 6-10mm, and the biomass pellets have the characteristics of high calorific value, no pollution and low ash content, which can be widely used in biomass power plants, biomass steam boilers, household fireplaces, drying furnaces and biomass gasifier. The overleft material pellet production project has obvious advantages in the pelletizing process: the pellet mill is equipped with a forced feeder to force feeding into the ring molding chamber, which can make the pellet mill run smoothly, do not block the materials, and produce efficiently. Specially design of broken screw feeding, so that the poor flow raw materials smoothly feeding.

Pellet mill: MZLH420, main motor power: 90kw, power of forced feeder: 0.75kw, design with 1T/H output , quantity: 3sets

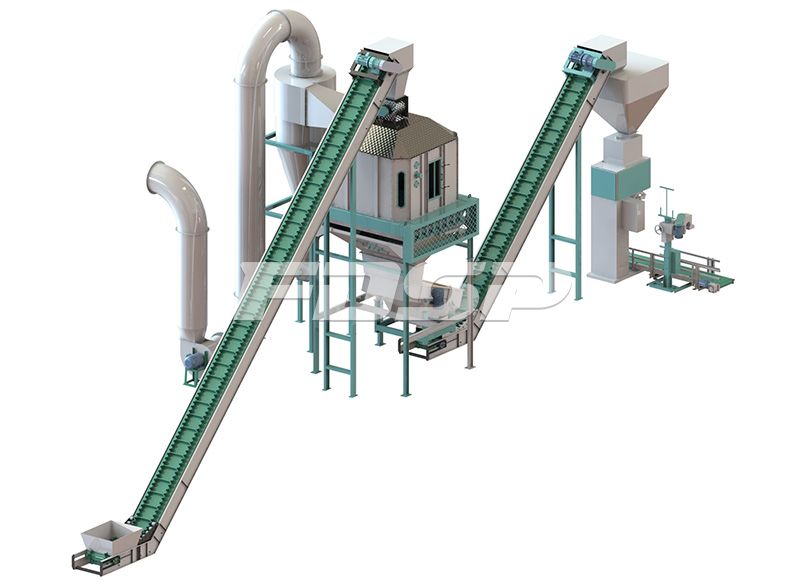

Cooling and packing process

In this cooling process of leftover material pellet production project, a cooler is used to reduce pellets temperature and decrease pellets moisture, low energy consumption, easy operation, high automatic degree, through the cooler cooling, pellets temperature is not higher than ambient temperature 5 ℃, after cooling the pellets moisture around 8-10%, particle density 650-750kg/m³.

According to the customer's local sales needs, the appropriate packing scale is selected for customer to sell products more easily. There are usually two specifications: small bag and ton bag. 20-50kg/bag for small bags, 500-1000kg/bag for ton bags. The packing scale has high automation degree, high packing accuracy, and The measurement by sensor in the weighing system is with high sensitivity and strong anti-interference ability.

Cooling equipment: SKLB2.5, cooling volume : 2.5m3 , design with 3-4t/h output.

Packing scale: SDBLY-K,bag size20-50kg/bag,packing speed: 3-5bag/min