Ring die fixed by bolts characteristics

■ Full automatic CNC ring die drilling machine is applied. The whole ring die processing is fully automatic controlled, and the holes of good smoothness are shaped at a time

■ Vacuum heat treatment technology reaches the most suitable working condition, which ensures the stability of ring dies.

■ Smooth holes make sure that pellets are of high output and quality.

■ Long working life

■ Different types and hole diameters can be processed.

Quality measurement of thermal treatment

■ Hardness

For each ring die, after thermal treatment, at least 8 points shall be measured on both sides of the ring die and inner circle surface by sclerometer. The surface hardness shall be as follow: stainless steel: HRC52-55, alloy steel: HRC60-62; the differences between each points shall be no more than HRC3.

■ Surface quality

Ring die surface shall be much smooth after being vacuum heat treated.

■ Roughness of holes

Check roughness of holes by comparing the roughness of samples.

■ Microstructure after quenching

Observe the microstructure of material by metallographic microscope, and the microstructure shall be martensite + carbide + retained austenite.

■ Ring die deformation

Tiny deformation will occur after being heat treated by vacuum hardening. Measuring tools shall be applied, and make sure dimension variation range shall be +0.5~1mm.

Dies-steel mould

Our dies are manufactured in the following steels:

■ X46Cr13 (i.e."stainless" steel or "chrome-steel")

■ 20MnCr5 (i.e."alloy" steel)

■ 18NiCrMo5 (i.e. similar to 20MnCr·5 but with a higher alloy content).

The X46Cr13 steel dies are vacuum / through hardened. The heat treatment achieves 53-55HRc hardness on the surface and in the core. The high chrome content makes it corrosion resistant. Although it costs more than a normal alloy, X46Cr13 is by far the most common material used through out the feed milling industry.

Dies made in 20MnCr5 and18 NiCrMo5 steel, on the other hand, are case hardened to obtain 60-62HRc hardness for approximately 0.8-1.2mm. Under the case hardened layer the steel remains malleable and therefore less brinle. The dies made of this steel are more resistant for pelleting extremely difficult fibre-rich products such as beet pulp, alfalfa, straw and hay.

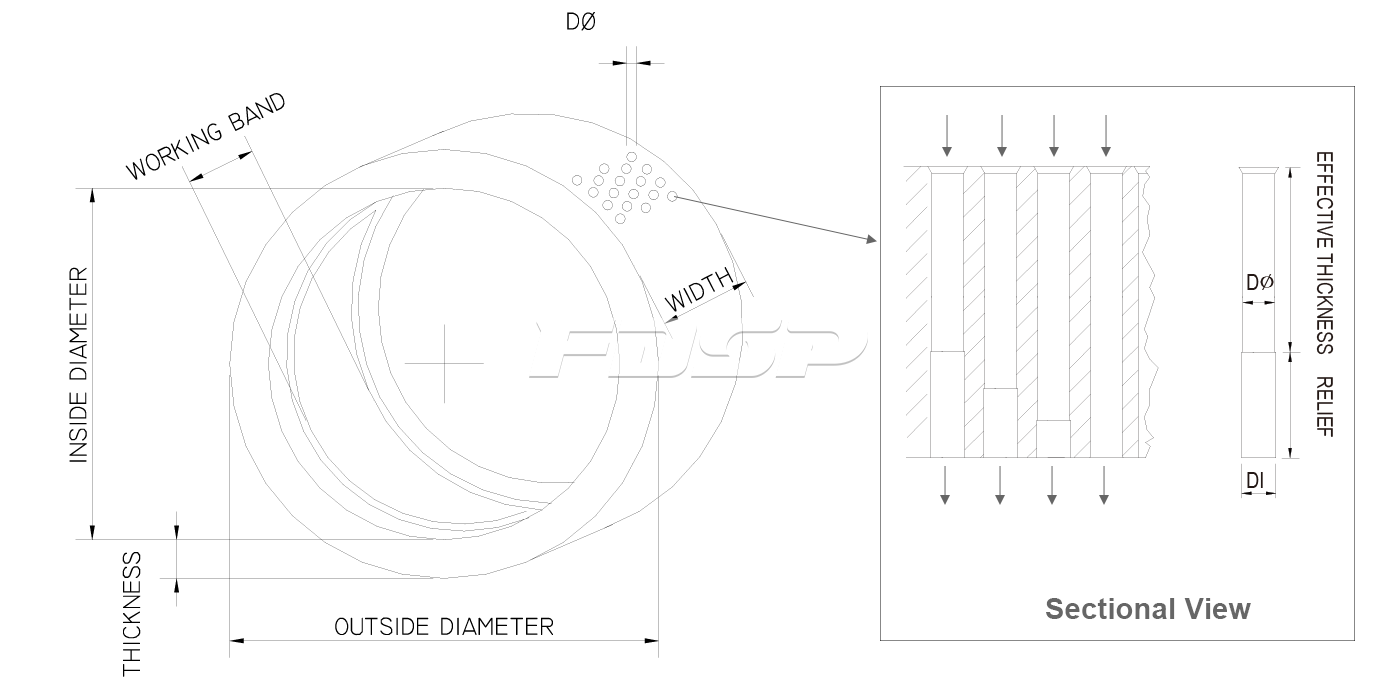

Dies-perfect drilling

FDSP dies have an extremely precise and regular perforation: the "honey comb" layout of the holes is faultless.

Deep hole via gun drill drilling: ring die holes array evenly, uniform wall thickness between holes, to ensure ring die works successfully in pellet mill with smooth surface of pellet. It is important to upgrade smooth and polish level of ring die holes in order to decrease temperature difference, lower energy consumption, raise capacity, and reduce loss of nutrition FDSP reach international advanced level relate to hardness of ring die, evenness and smoothness of holes.