Generally, the process flow of a small and medium-sized livestock and poultry feed factory consists of raw material receiving, crushing, batching, mixing, granulating, cooling and screening, and finished product packaging. The core production equipment is pulverizers, mixers, pelletizers, etc. The selection of these equipments plays a vital role in the feed quality of a feed mill. The following Liangyou shares will briefly describe the functions and selection of several core equipment.

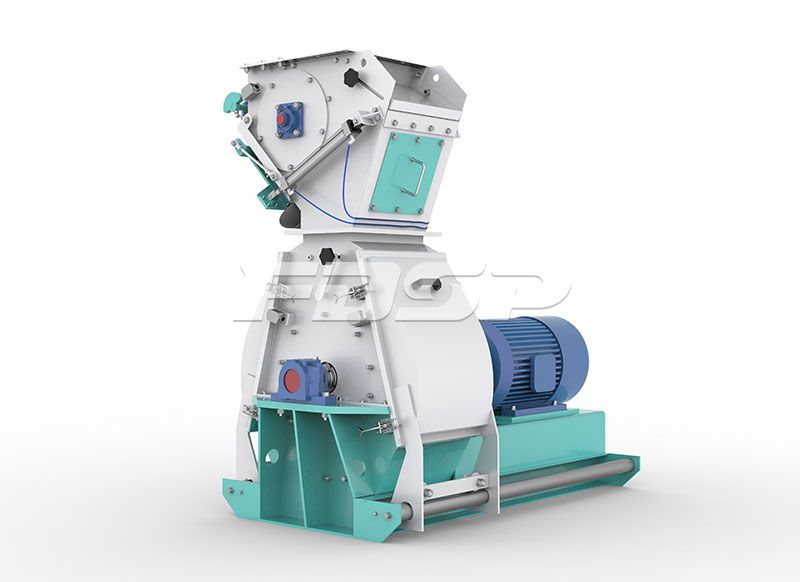

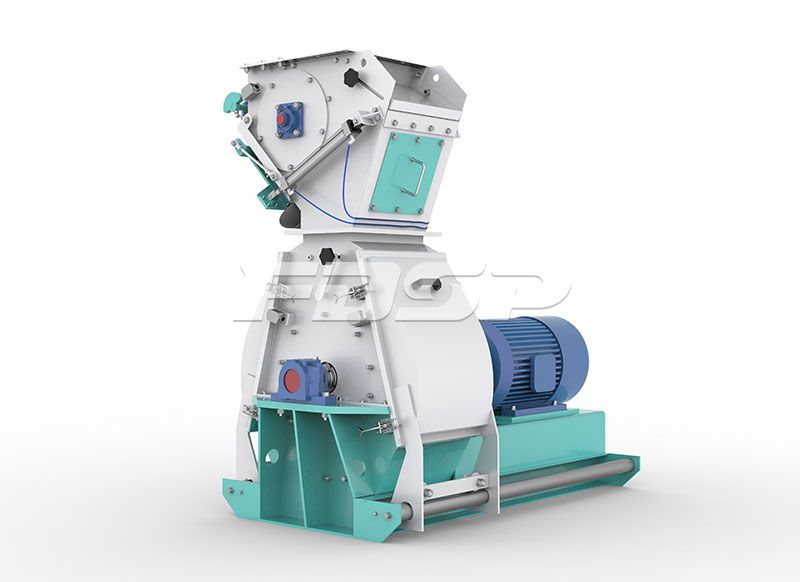

1 Shredder

The power equipment of the pulverizer generally accounts for about 1/3 of the total power equipment of the feed factory. How to reasonably select advanced pulverizing equipment, design the best process route, and use the pulverizing equipment correctly is of vital importance to feed manufacturers. For livestock and poultry feed, SFSP series hammer mills are generally used. Liangyou SFSP series grinder has high efficiency, good crushing performance and good adaptability. It is widely used by customers and is suitable for the production of various pig feed, chicken feed, and cattle and sheep feed.

2 Mixer

In feed production, the working status of the main mixer not only determines the quality of the product, but also plays a decisive role in the productivity and feed quality of the production line, so it is known as the "heart" of the feed factory. At present, the most widely used double-shaft paddle mixer on the market is the Liangyou SHSJ series double-shaft high-efficiency mixer. The mixing speed is fast, and the mixing uniformity is as high as 95%. In the fluid state, the mixing effect of diffusion is better. During the use of the mixer, the sealing strips need to be replaced regularly to prevent material leakage to ensure that all materials maintain uniformity during the mixing process; at the same time, the mixer should be cleaned regularly to prevent materials sticking to the inner wall of the mixer in a humid environment Breeding of bacteria and mildew affect the quality of livestock and poultry feed.

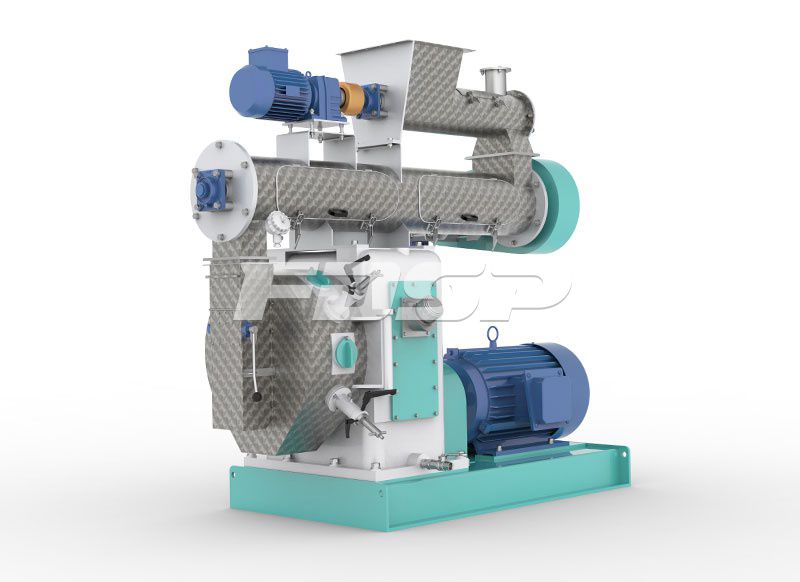

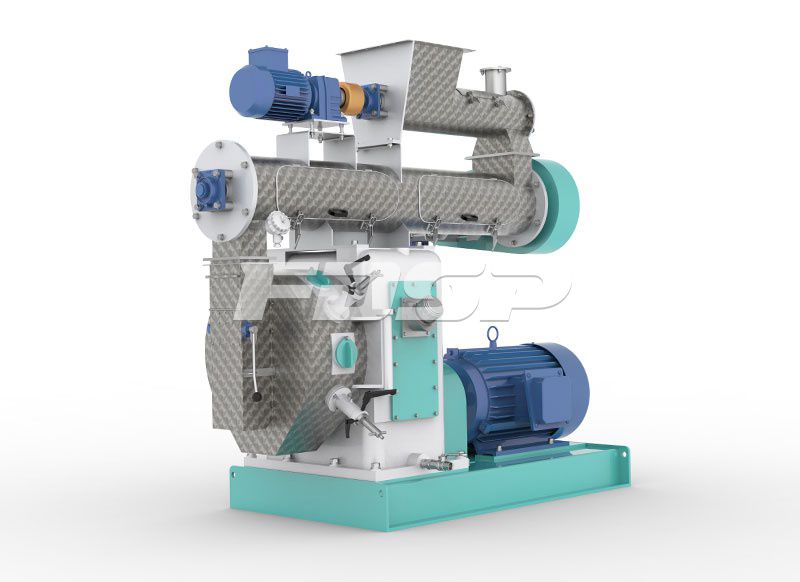

3. Granulator

The pellet mill is the key equipment for the production of pellet feed, and it is also one of the equipment with the largest power consumption in the feed factory. Its energy consumption accounts for more than 40% of the total energy consumption of the feed factory. Therefore, it is necessary to comprehensively select the equipment consider. At present, ring die pelletizers are mainly used in the market, which are characterized by large output, uniform discharge, good material shape, and stable quality. According to the different driving methods, ring die pellet mills can be divided into gear type and belt type. They adopt gear transmission and have high efficiency. Its output is 15% higher than that of belt type. For example, Liangyou SZLH series pellet mill adopts high-precision aviation grade. Gear grinding technology ensures smooth gear transmission and low noise. With the humanized design concept, the whole machine has the characteristics of small footprint, low power consumption, low noise and high safety performance, which can create long-term and stable benefits for the feed factory.

The mixed powdered feed is pelletized, which can improve the nutrition and edible quality of the feed to varying degrees. Pelleting is not only suitable for livestock and poultry feed, but also suitable for aquatic products and special feeds. Due to the different varieties and components of feed ingredients and the different scales of finished products, there are also different requirements for the performance and structural parameters of the pelleting equipment. Liangyou shares will tailor each production line according to the actual situation of the customer to maximize the benefits for the customer.

A good selection of core equipment can achieve a multiplier effect with half the effort for a continuous production feed factory, which can effectively reduce equipment maintenance time and improve feed production efficiency. In addition to the above three core equipment, the feed factory also has some supporting equipment, such as scraper conveyors, bucket elevators, feeding augers, rotary vibrating screens, distributors, etc. Liangyou will provide you with a full-line configuration plan, and create a one-stop service system from early design and manufacturing to later construction and maintenance.