There are many types of feed processing equipment, among which the key equipment that affects feed pelleting is nothing more than crushers, mixers, and pelletizers. In today's increasingly fierce competition, many manufacturers purchase advanced production equipment, but because of incorrect operation and use, equipment failures often occur. Therefore, it should not be ignored for feed manufacturers to correctly understand the precautions for the use of equipment.

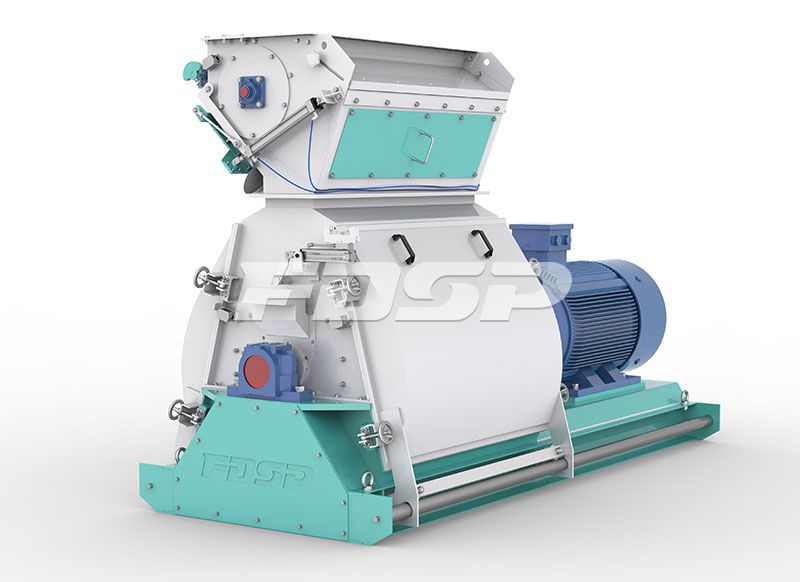

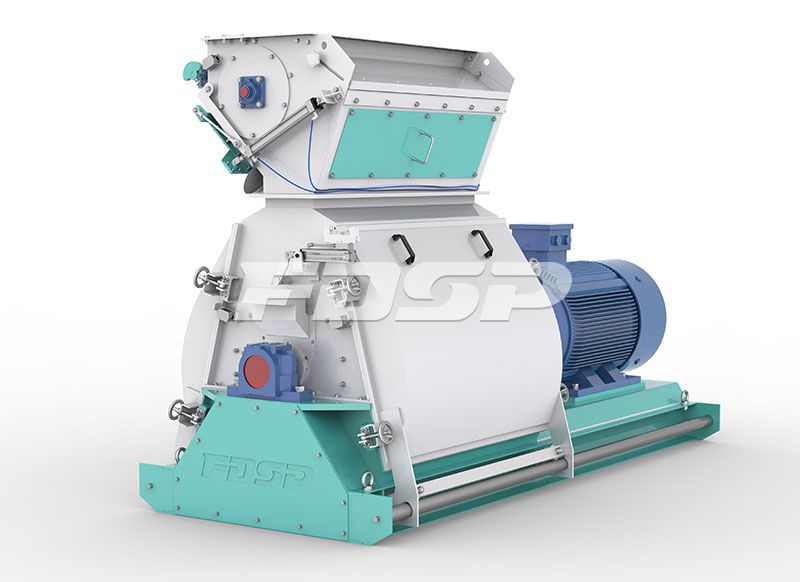

1. Hammer mill

There are generally two types of hammer mills: vertical and horizontal. The main components of the crusher are hammers and screens. The hammers must be durable and wear-resistant and have a certain degree of toughness, and are arranged in a balanced manner to avoid equipment vibration.

Precautions for the use of the grinder:

1) Check the lubrication of the connecting parts and bearings before starting the machine. Run the machine empty for 2-3 minutes, start feeding after normal operation, stop feeding after the end of the work, and run the machine idling for 2-3 minutes, and wait for all the materials in the machine Turn off the motor after emptying.

2) When the hammer is worn to the center line, it should be turned around immediately. If the four corners are worn to the center, new hammers need to be replaced. Note: The original arrangement order should not be changed during the reinstallation, and the weight difference between each group of hammers should not exceed 5g, otherwise it will affect the balance of the rotor.

3) The air net system of the pulverizer is very important to improve the pulverization efficiency and reduce the dust, and it should be matched with a pulse dust collector with good performance. After each shift, clean the inside and outside of the dust collector to remove dust, and regularly inspect, clean and lubricate the bearings.

4) The materials shall not be mixed with iron, crushed stones and other sundries. If abnormal noise is heard during the work process, stop the machine for inspection and troubleshoot in time.

5) The working current and feeding amount of the feeder at the upper end of the crusher should be adjusted at any time according to the different materials to prevent jamming and increase the crushing amount.

2. Mixer (take paddle mixer as an example)

The double-shaft blade mixer is composed of a casing, a rotor, a cover, a discharge structure, and a transmission device. There are two rotors with opposite rotation directions on the machine. The rotor is composed of a main shaft, a blade shaft, and a blade. The blade shaft crosses the main shaft, and the blades are welded to the blade shaft at a special angle. The blades with animal material rotate along the inner wall of the machine tank on the one hand and move to the other end, and the animal material is turned over, interlaced and sheared, so as to achieve the effect of rapid mixing and uniformity.

Precautions for the use of the mixer:

1) After the main shaft rotates normally, the additives should be added after the main material enters half of the batch. The grease is sprayed into the machine after all the dry materials enter the machine, and the material can be discharged after spraying and mixing for a period of time;

2) When the machine is stopped and not in use, no grease should be left in the grease adding pipeline, so as not to block the pipeline after solidification;

3) Metal impurities must not be mixed into the materials when mixing, which will damage the rotor blades;

4) If there is a shutdown during use, the material in the machine should be drained before starting the motor;

5) If there is material leakage in the discharge door, check the contact between the discharge door and the sealing seat of the casing. If the discharge door is not closed tightly, adjust the position of the stroke switch or adjust the bottom adjustment nut of the discharge door, or replace the sealing strip.

3. Ring die granulator

The pellet mill is the key equipment in the production process of each feed factory, and it can also be said to be the heart of the feed factory. The correct use of the granulator directly affects the quality of the finished product.

Precautions for the use of the granulator:

1) During the production process, if too much material enters the granulator, which causes the current to rise suddenly, the manual discharge mechanism must be used to discharge the material outside the machine.

2) When the door of the granulator needs to be opened, the power must be cut off first, and the door can only be opened after the granulator completely stops running.

3) When restarting the granulator, you must manually rotate the granulator ring die (one circle) before starting the granulator.

4) When the machine malfunctions, the power must be cut off and shut down to remove it. It is strictly forbidden to remove it with hands, feet, wooden rods, or irons during operation; it is strictly forbidden to start the motor rigidly.

5) When using a new ring die for the first time, a new press roller must be used. Oil can be mixed with fine sand (all through 40-20 mesh sieve, and the ratio is: oil: sand is about 6: 2: 1 or 6: 1:1) Wash the ring mold for 10 to 20 minutes before it can be put into normal production.

6) Assist the maintenance worker to check and refuel the main motor bearings once a year.

7) Assist the maintenance worker to replace the lubricating oil 1-2 times a year for the gearbox of the granulator.

8) The permanent magnet cylinder should be cleaned at least once per shift.

9) The steam pressure entering the jacket of the conditioner is not higher than 1kgf/cm2.

10) The pressure of steam entering the conditioner is in the range of 2-4kgf/cm2 (generally, it is appropriate not to be less than 2.5 kgf/cm2).

11) Lubricate the press roller 2-3 times per shift.

12) Clean the feeder and conditioner 2-4 times a week (once a day in summer).

13) The distance between the cutter and the ring die is generally not less than 3mm.

14) During normal production, it is strictly prohibited for the main motor current to exceed the rated current, that is, overload operation.