Due to the large production of pellet feed in feed enterprises, the demand for pellet mill ring die has also increased. Some small manufacturers of poor quality ring molds have also flowed into the market, and some feed companies are attracted by low prices. However, such inferior ring molds have rough processing and low service life. The important thing is to imitate low precision, poor concentricity, and ring mold work. Disadvantages such as large noodle bounce.

Long-term use of inferior ring die will greatly shorten the service life of the granulator. If you purchase a Liangyou pelletizer, the ring die will be worn to varying degrees after long-term operation. If the customer replaces the ring die with a non-original or low-quality ring die, it will cause damage or oil leakage in a short period of time. The host will often fail, affecting the normal operation of the granulator, greatly affecting the efficiency of the enterprise, and the gain is not worth the loss.

Why does Liangyou suggest that it is better not to use some inferior ring molds on the market?

1. Inferior ring molds pursue low prices and high sales, so there is a consideration in the selection of materials, and low-cost steel billets are used as raw materials. The molecular structure of the billet is not tight, the toughness is not up to the requirement, and the degree of wear resistance is poor. The ring die made of the billet has a short service life and is easy to crack. Liangyou original series ring die adopts imported high-carbon high-chromium stainless steel forging blanks to optimize the content of carbon and chromium to improve its wear resistance, corrosion resistance and strength;

2. Inferior quality ring molds are manufactured with rough technology and cannot achieve accurate precision. Like the joint surface of the ring die and the hoop, as long as there are more than a dozen wire errors in the processing, the hoop will not be able to hold the ring die tightly, causing the ring die to shake and rub during the high-speed operation of the pellet mill, and the hoop and the empty shaft drive wheel will appear. At the same time, it was damaged and the body vibrated.

3. The processing technology of high-quality ring die is difficult to imitate. Liangyou original series ring molds adopt imported gun drills and multi-station group drills. The mold holes are formed at one time and have high smoothness. At the same time, microscope inspection is used to ensure the high quality of the product, ensure the efficiency of pellets, and the shape is smooth and flat; the finished product has a beautiful appearance. High quality, improve market competitiveness for feed enterprises.

Fourth, it is difficult for small ring die production plants to have some advanced equipment. Generally, the earth method pit furnace is used for quenching. After quenching, the hardness of the ring die made by this equipment is inconsistent, the deformation coefficient is large, and the ring die is easily out of round. During the operation of the granulator, the press roller will frequently hit the ring die, which will increase the vibration and noise and reduce the output, which seriously causes the granulator to fail to work normally. Liangyou adopts vacuum furnace heat treatment technology to ensure the quality and service life of the ring die.

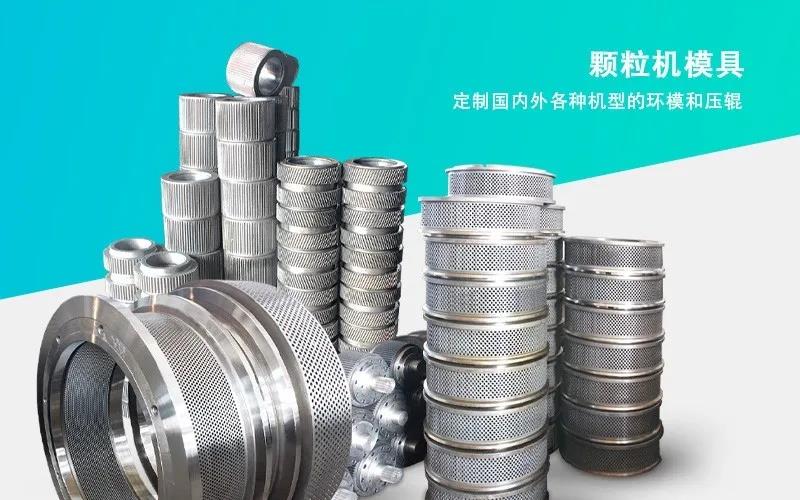

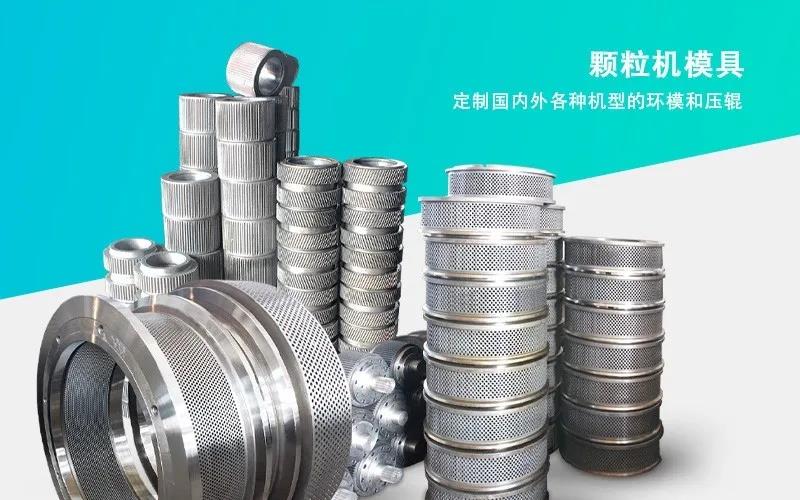

The quality of the molds and accessories in one part of the granulator will have a great impact on the operating efficiency, quality, and output of the entire equipment. It is recommended to use Liangyou's high-quality standard ring molds, which can help you safe, efficient, and safe for a long time. Low-consumption production. In addition, we can design and customize various molds according to the customer's equipment technology, formula and particle quality requirements; we can customize the ring molds, pressure rollers and other accessories of different countries, different models, different materials and different industries for you.