Project Description

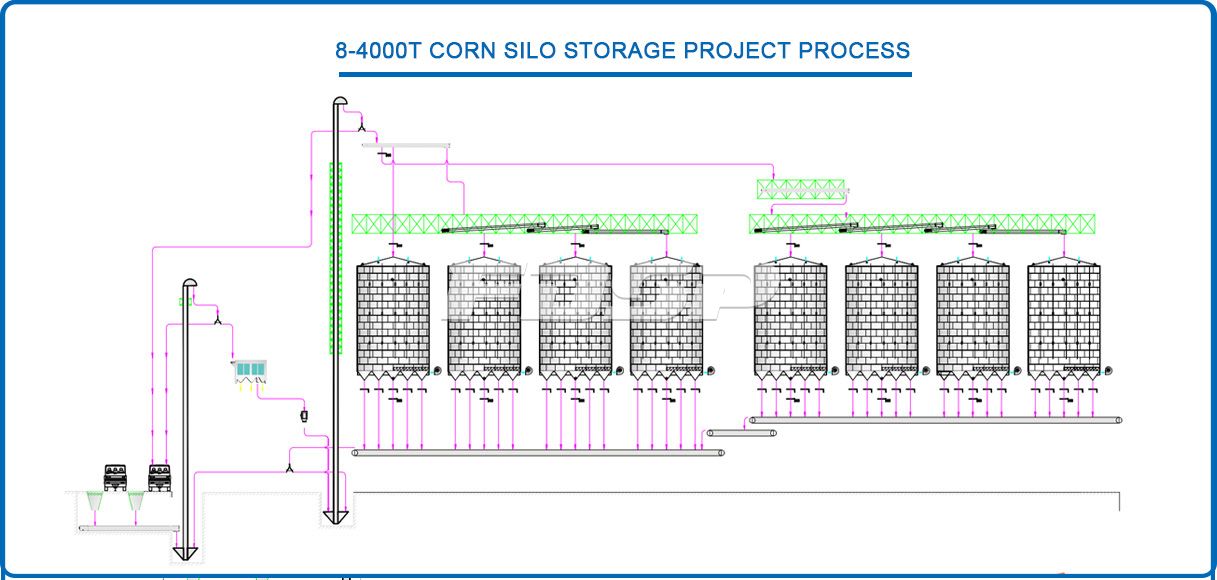

(1) The unloading section is double-sided unloading, the unloading grid screen is the truck load-bearing model, and both sides of the unloading pit are equipped with centralized dust removal to improve the working environment;

(2) The cleaning section is equipped with large-output double-drums cleaner and permanent magnet tube, and the cleaning output is 150TPH.

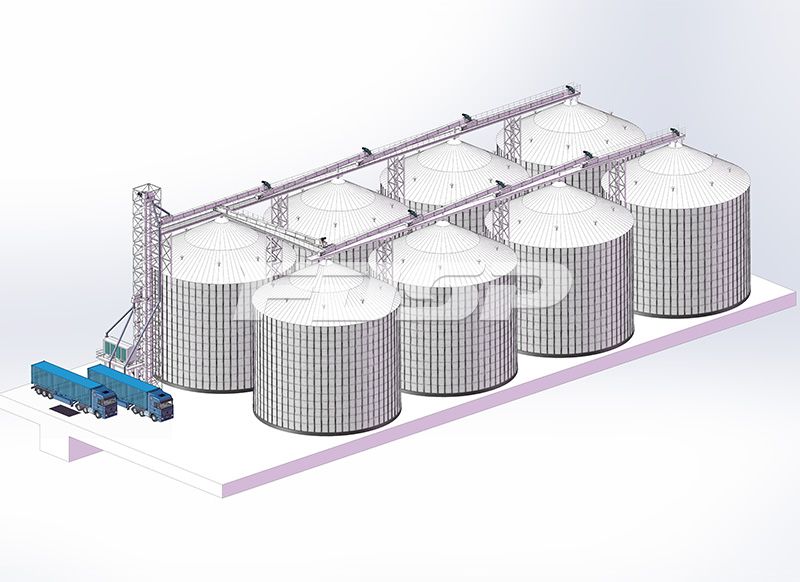

(3)Silo storage section: In this scheme, it is mainly to store corn. The silo is equipped with temperature measuring and ventilation system, which can effectively control the grain situation.

Features of the engineering process design:

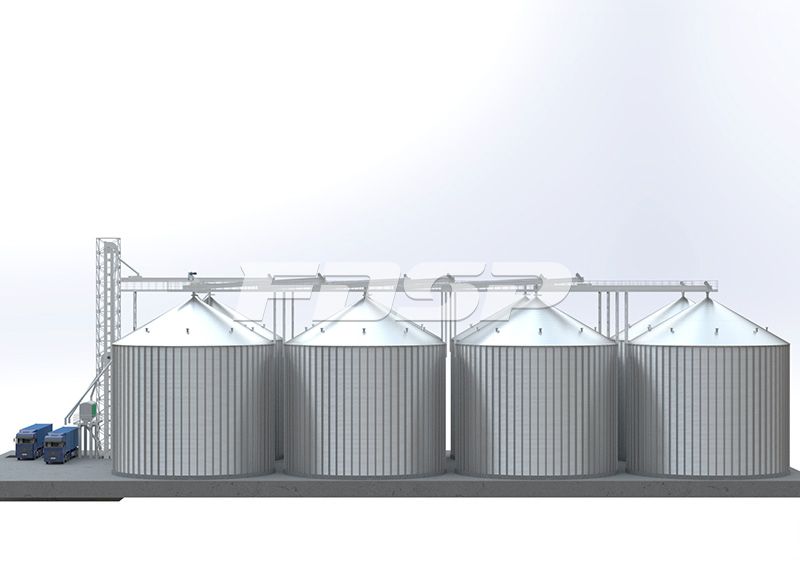

(1) Bulk loading trucks at the bulk unloading site at the request of customers;

(2) There are two ways to load raw materials, one is to load materials in silos, the other is to load raw materials immediately after cleaning;

(3) The reinforcement of the silo in this project is designed as external reinforcement, which is treated with hot dip zinc, resulting in less residual in the silo;

(4) The base of the silo bottom is designed in the form of concrete flat bottom. The material output adopts the sweep auger.

Other instructions:

For different projects, different customer requirements, different processes, the following is the specific engineering options:

(1) Cleaning system (this part can be omitted if the raw materials are clean);

(2) Ventilation temperature measuring system (if the raw materials are relatively dry, and the storage time in the silo is less than 7 days in winter and less than 4 days in summer, this part can be saved);

(3) Grain exchange system (if the raw materials are relatively dry, and the storage time in the silo is less than 60 days in winter and less than 30 days in summer, this part can be saved).

(4)Bulk loading section can be added to the silo outlet according to the need, and a small bulk silo (between 50T and 100T) can be set up, which is more conducive to on-site management.

(5) Customers can choose screw silo or assembly silo according to their own needs.