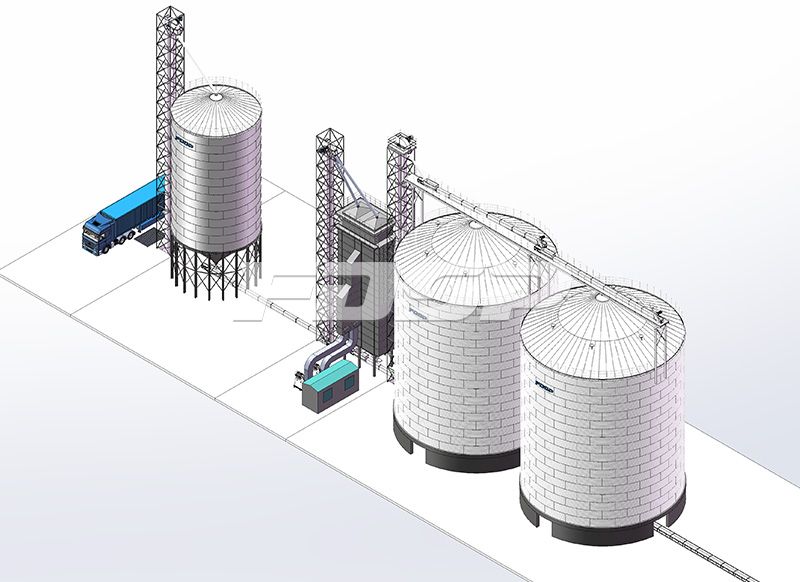

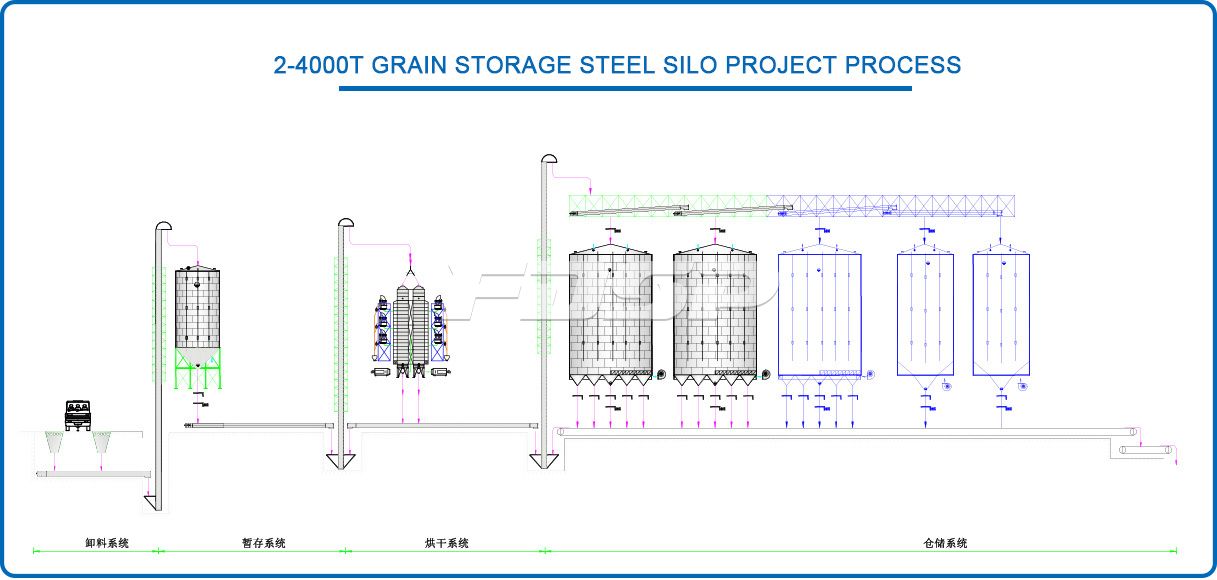

Project Description

(1) the unloading section is double-sided unloading, and the unloading grid screen is the truck load-bearing model;

(2) temporary storage and drying stage: the temporary storage silo is 1-1000m3 assembly silo, which is used to buffer the difference between the feeding speed and the drying speed, so as to achieve the purpose of rapid unloading and even drying;

(3) The storage section is 2-4000t grain assembly silo, and the incoming output is 50TPH. The silo is equipped with temperature measuring and ventilation system, which can effectively control grain situation. Blue silos are reserved for customers.

Features of the engineering process design:

(1) Equipped with temporary storage before drying, which is more conducive to on-site production management of customers;

(2) The silo bottom adopts heavy belt conveyor, which can save more equipment and power compared with the chain conveyor;

(3) In the design of silo foundation, the ventilation screen is designed in the form of detachable and easy to replace, so as to keep the air duct unobstructed and the ventilation effect good, and effectively control the grain situation in the silo;

(4) Concrete flat bottom for silo base;

Other instructions:

For different projects, different customer requirements, different processes, the following is the specific engineering options:

(1) cleaning system (since the raw materials of this project are clean and free of impurities, the cleaning system is not equipped; If there are too many impurities in the raw material, the cleaning system can be added before entering the temporary storage.

(2) ventilation & temperature measuring system (if the raw materials are relatively dry and the storage time in the silo does not exceed 7 days in winter and 4 days in summer, this part can be saved);

(3) Grain exchange system (if the raw materials are relatively dry and the storage time in the silo is less than 60 days in winter and less than 30 days in summer, this part can be saved);

(4) Customers can choose screw silo or assembly silo according to their own needs.