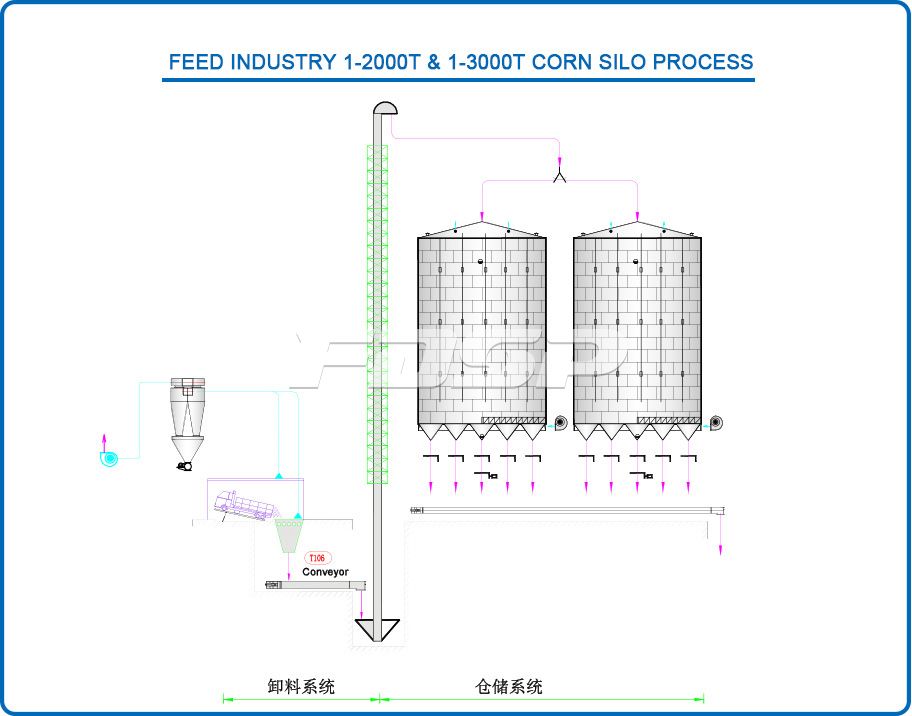

Project Description

1)The unloading process the loaded by hydraulic back flip unloading, the grizzly cannot carry the truck. dumping hoper and dumping shed is equipped with de-dusting system to improve the working condition.

2) storage and discharging process: in this process, the main storage material is maize, there is temperature measuring and ventilation system inside the silo which could control the grain condition.

Features of the engineering process design:

1) adopt the hydraulic back flip loading according to customer's inquiry.

2) in this process, consider the large unloading capacity, there will be much dust in confined unloading shed when back-flip loading, so we make extra two de-dusting points on the top of unloading shed which closed to the dumping hopper besides the dedusting point on the dumping hopper.

(3) as the raw material for this customer is very clean so the cleaning system is not equipped in this project.

4) the silo base is designed as concrete flat bottom type, discharging by sweeping auger.

Other instructions:

For different projects and different customer requirements, the process will be also different; the following could be options during the process design:

1)the customer required two different capacity silo in this project, but usually we suggest the silo in one project with same specifications.

(2) cleaning system (the cleaning system can be added before the material go into the silo if there is many impurities in raw material);

(3) ventilation and temperature measuring system (if the raw materials are relatively dry, and the storage time in the silo is less than 7 days in winter and less than 4 days in summer, this part can be removed);

(4) the silo changing system (if the storage time in the silo exceeds 60 days in winter and 30 days in summer, the warehouse changing system shall be considered);

(5) because of the site limitation and the customer need the same general height of two silo, we specially designed the 2000T silo with ¢12.8m×20.16m, 3000T silo with ¢14.6m×21.28m, but usually, we recommend 2000T silo with ¢14.6m×15.68m, 3000T silo with ¢16.5m×17.92m

6) customers can choose helix silo or bolt silo according to their own needs.