Recently, the Chongqing 60,000-ton-per-year high-grade pig feed production line, constructed by FDSP, successfully completed its acceptance testing. The client for this project has cooperated many times with FDSP for a long-term. The successful completion and acceptance of this project not only demonstrates a high level of recognition of FDSP's technical strength and service quality but also lays a more solid foundation for future cooperation between the two parties.

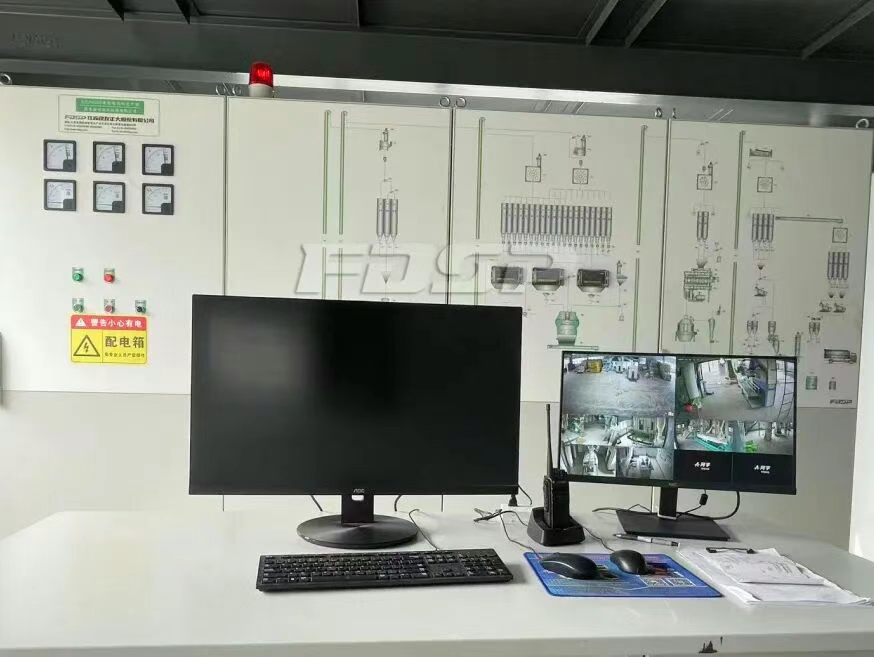

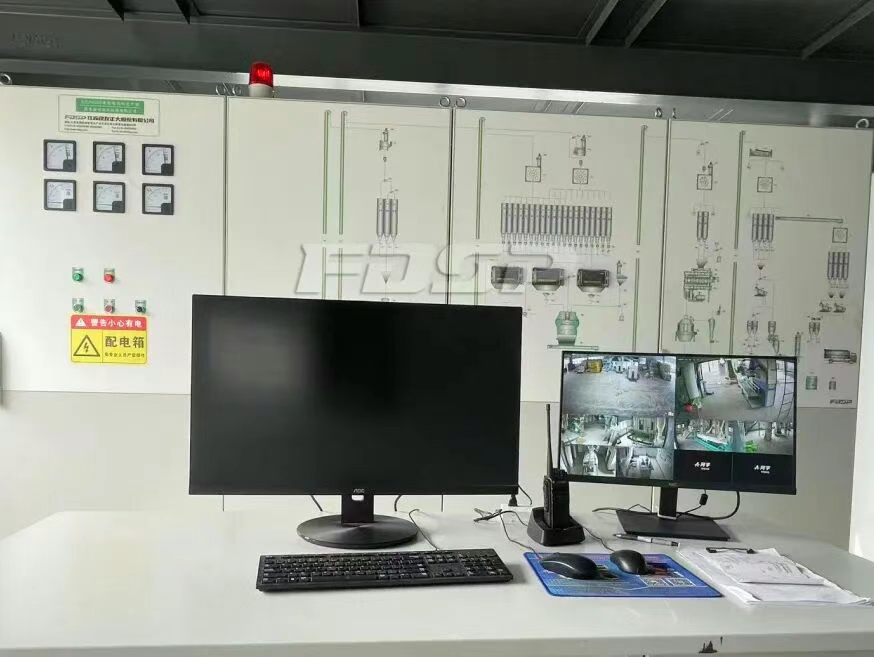

The Chongqing Phase II high-grade pig feed production line continues the advanced design concept of Phase I, featuring all main machine with the highest configuration and full-screen control, perfectly integrating high efficiency, stability, and intelligent control. All main machines, including the crusher, mixer, pellet mill, cooler, crumbler, and screener, are the latest models from FDSP. This series of high-end configurations results in significant advantages for the entire production process, including high output, low energy consumption, fewer personnel, and a high degree of automation.

Furthermore, this production line keeps pace with the demands of modern feed mills, employing a high-grade pig feed pellet mill. The pellet mill's ring die and rollers are made of high-quality alloy materials, offering excellent wear resistance and a long service life. By adjusting the ring die aperture and compression ratio according to different pig feed formulations and pellet requirements, pelleted feed meeting quality standards can be produced. The pellets are cooled using an impeller-type cooler designed by FDSP. The evenly distributed impellers inside the cooler ensure uniform tumbling of the pellets during cooling, resulting in excellent cooling performance. The fan is equipped with a vibration damping device; through special damping structures and materials, noise and vibration generated during fan operation are reduced, improving the working environment. This provides feed companies with a complete, efficient, and energy-saving solution.

FDSP consistently regards product quality as the lifeline of its business development. During equipment installation, FDSP's professional installation team has established detailed quality control points, strictly adhering to installation specifications and standards to ensure installation quality. In the production commissioning phase, technical personnel provide full-process guidance and comprehensive optimization to ensure normal equipment operation. FDSP's efficient engineering response mechanism provides timely and attentive service to clients throughout the entire process, from initial consultation and planning to post-project maintenance, ensuring clients experience meticulous care and making FDSP a most trustworthy partner.

Looking ahead, FDSP will further strengthen its cooperation with customers, gain a deeper understanding of their needs and market dynamics, and provide them with more high-quality and efficient products and services. By working hand in hand with customers to jointly explore and innovate in the high-end feed market, FDSP will help customers enhance their market competitiveness and achieve a win-win development situation.