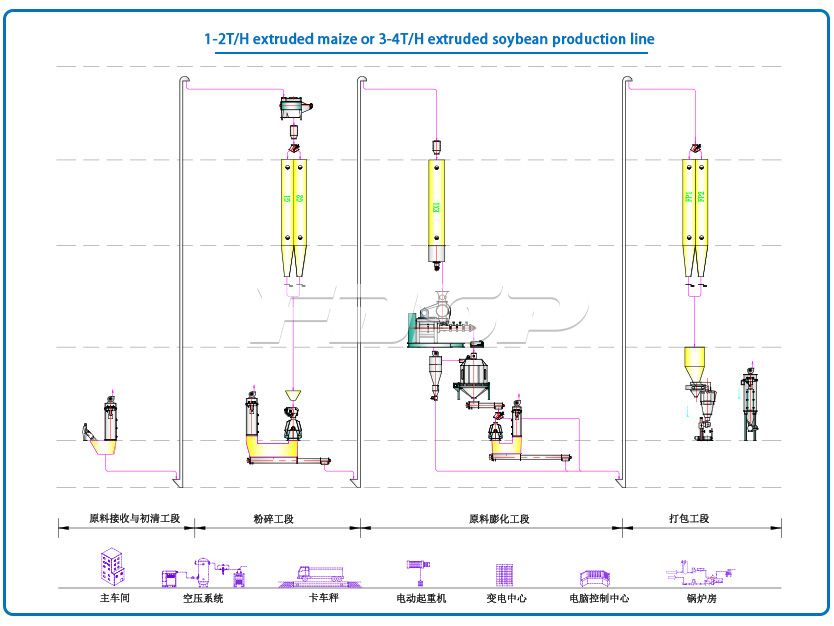

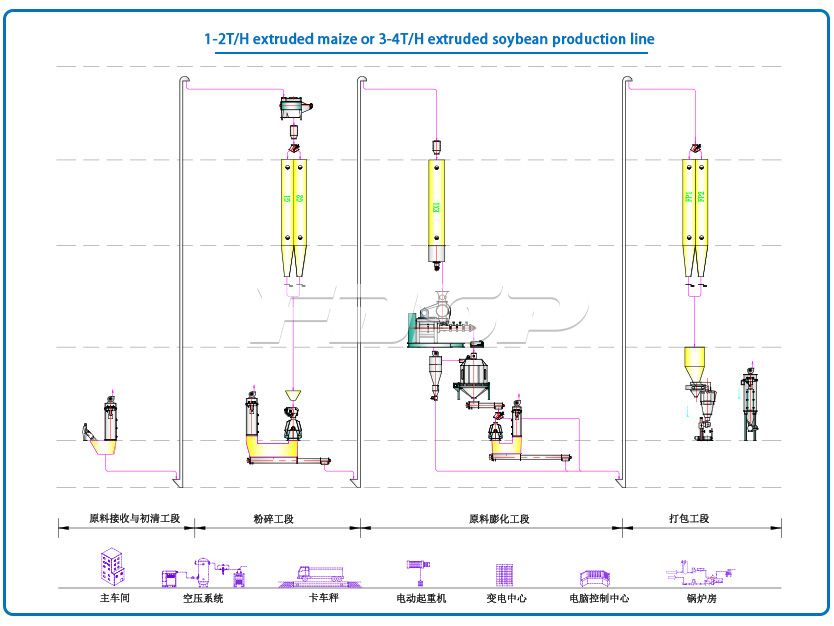

The following introduction and instructions are based on 1-2T/H extruded maize or 3-4T/H extruded soybean production line.

Definition of “Extruded soybean/maize”:

Expanded soybean is kind of material for feed through extrusion which retains the nutrition of soybean itself, while removes the anti-nutrition factor of soybean, it is a good substitute material for protein source and be with rich oil fragrance, high nutritional value, good palatability. It has good feeding effect on broilers, layers, piglets and aquatic animals. Especially for piglet feed, it can replace soybean meal, fish meal to prevent piglet diarrhea, improve palatability, improve piglet growth rate.

Expanded corn, also known as expanded corn meal, refers to the starch gelatinization process of corn under the function of water, heat, mechanical shear, friction, rubbing and pressure difference. High attractive and healthy expanded corn has strong popcorn flavor and good palatability, strong attractivity, and can increased food intake. High digestibility and low degree of fermentation in large intestine has higher protection rate against diarrhea of piglets.

Raw materials:

Raw material extrusion mainly are soybean and maize, other feed raw material also can be processed.

Brief introduction for flow process:

raw material extrusion has high requirements for curing and conditioning, it could improve the palatability and increase nutrition of feed after adding extruded material into feed formula with certain proportion, it can also effectively improve the breeding efficiency, reduce the breeding cost and increase economic benefits. This line can be used to produce 1-2T/H expanded corn or 3-4T/H expanded soybean. One crushing line, one extruding line and one packing line are adopted. The total power of the equipment is about 352KW.The construction area of the production area is about 11x10.5x18.5m (height);Matching with 0.5T boiler. The whole line is characterized by compact design and reasonable structure, and the satisfaction of environment protection requirements, meanwhile it can be directed to customers design.