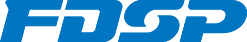

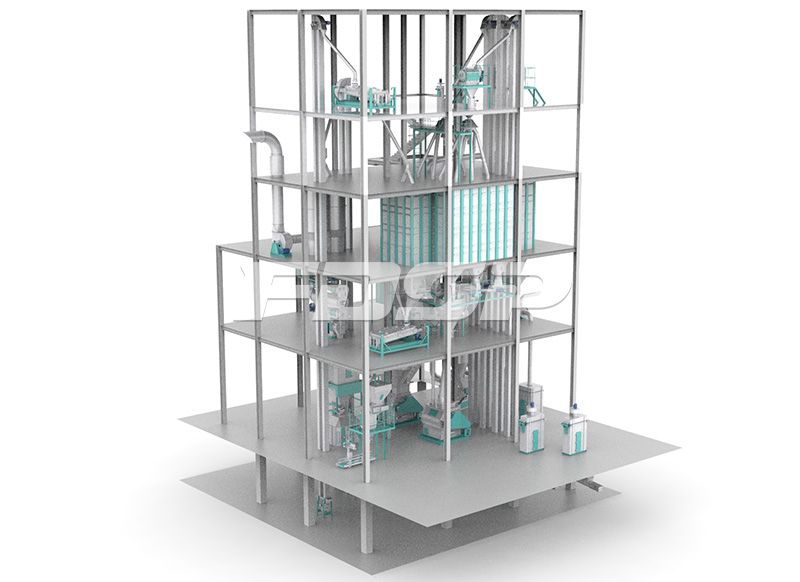

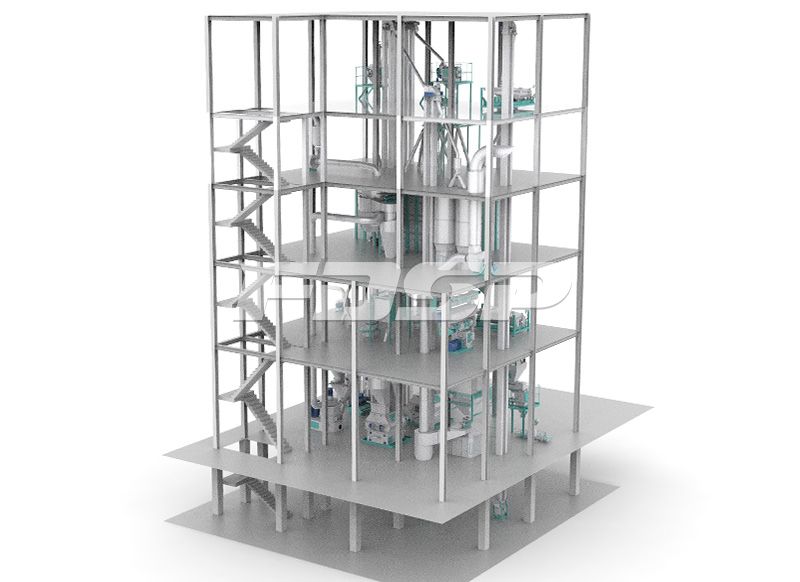

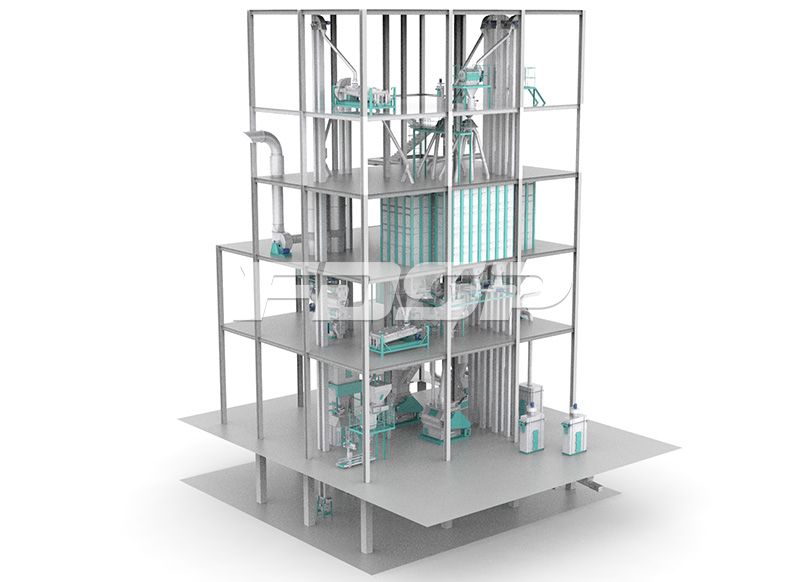

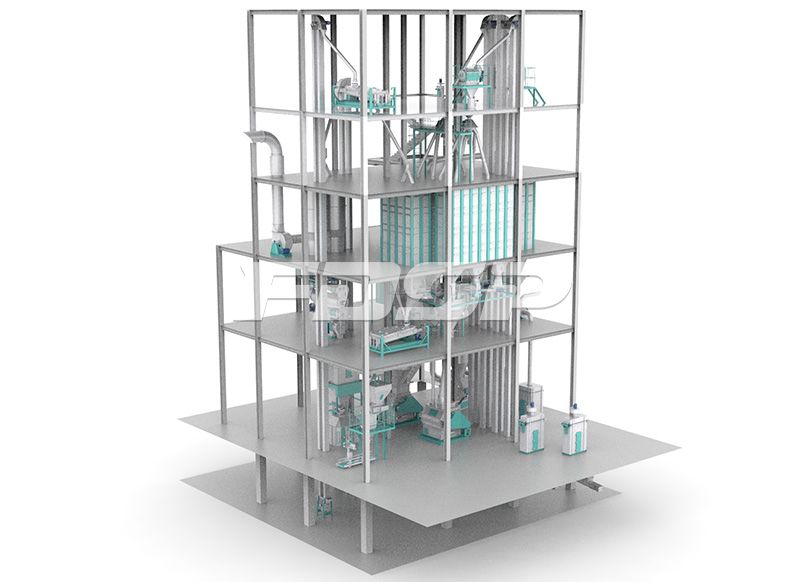

Technological characteristics and introductions:

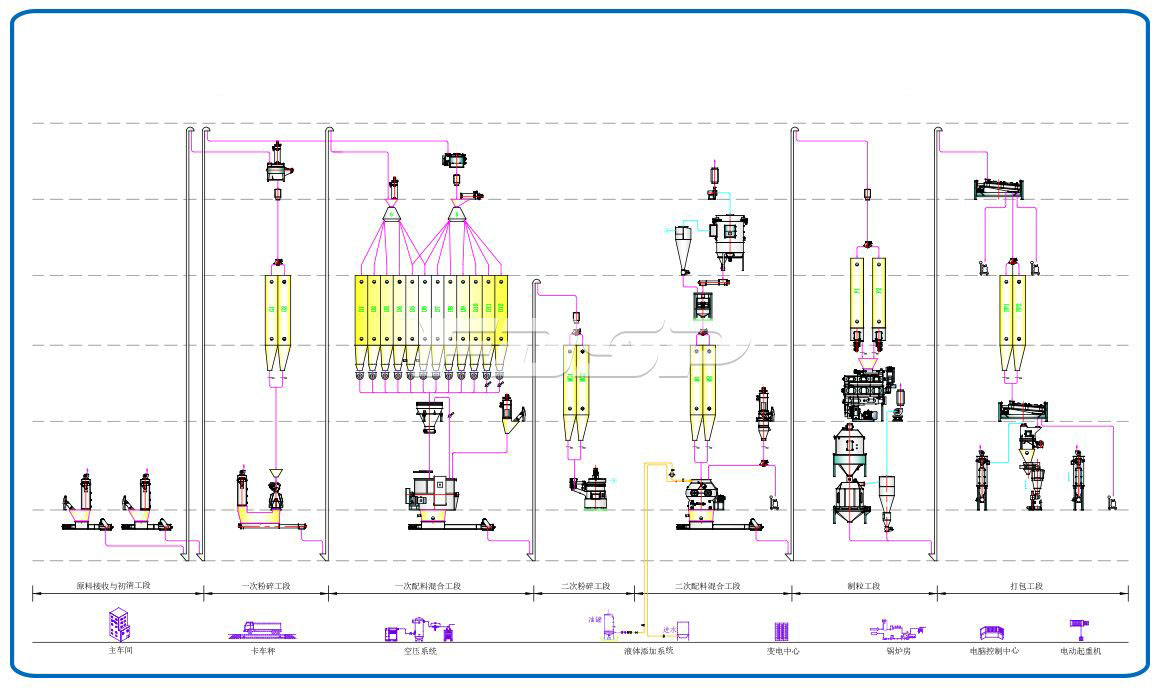

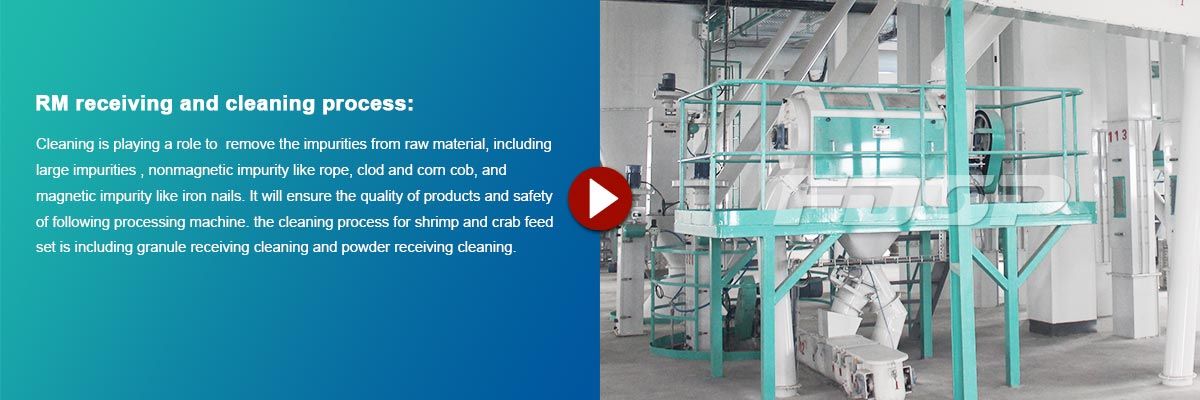

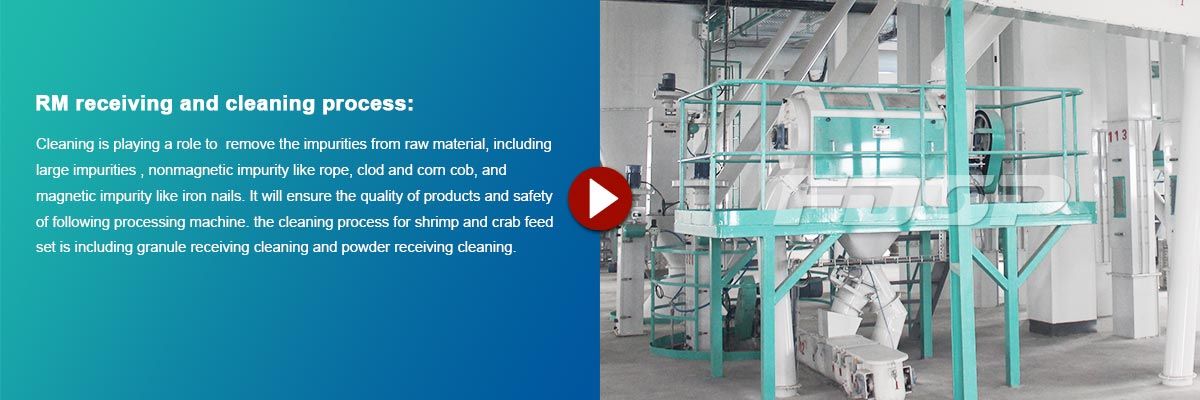

RM receiving and cleaning process:

In this process, the clean system for granule receiving and cleaning is separated from powder receiving and cleaning, dust collection are individual which is with the better effects.

cleaner: granule precleaner SCY63, output 10-15t/h, powder cleaner SQLZ60×50×100, output 10-15t/h.

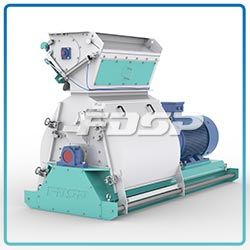

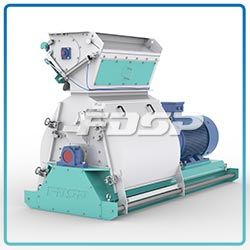

First coarse grinding process:

1set of hammer mill is adopt in this process, 2 grindings bins are equipped to cross exchange different raw material crushing ; The impurities could be removed from raw material by magnetic separation equipment before grinding bins to ensure the safe running of hammer mill.

Grinding equipment: hammer mill SFSP668×600, 55KW, output 2-3t/h(¢1.5mm screen hole size)

First batching and mixing process:

In this process, we use 12pcs batching bins, one batching scale is controlled by FDSP developed independently batching program, achieve accurate quick and slow feeding, quick batching and with high accuracy.

Weighing equipment: batching scale PCS05, weighing accuracy: dynamic≤3‰, static≤1‰.

Mixing equipment: mixer SLHY1, (11KW,500kg/batch), designed output 3-6t/h/set, homogeneity CV≤7%.

Pulverizing process:

As the high requirement for the raw material grinded particle size of shrimp and crab feed which usually is 80-120mesh. So we adopt 1 pulverizer with 2 grinding bins in this process to store material in turn, reducing the empty running for pulverizer. Pneumatic type discharging, cylone, pulse filter are used, the particle size after grinding can be adjust according to customers' needs.

Pulverizing equipment: SWFL110,110+11+2.2KW. Output 2-4t/h

Second mixing process:

Two batching bins and one mixer are used in this process extra manual adding hopper is adopt.

Mixing equipment: mixer SHSJ1, 11KW,500kg/batch, output 3-6t/h/set, homogeneity CV≤5%.

Granulation process:

This process adopts one belt driven shrimp specialized pellet mill SZLH420X, which is equipped with double shaft differential conditioner + retainer + jacket conditioner, effectively ensuring the pre-curing of granulation, two round pellet bins are equipped above the SZLH420x pellet mill together with dis feeder which can prevent the material arch. The finished product after granulation is put into the stabilizer for post-curing treatment to improve the stability of feed in water. Then enter the cooler to be cooled.

Pellet mill: SZLH420X,45×2KW, output for shrimp feed 1.5-2.5/H. Stabilizer SWDB4,1.1+1.5KW, Cooler SKLB4,1.1+1.5KW, volume 4m3 output 4-5T/H.

Packing process:

there are 2 FPbins in this process. Before the packing scale, the feed will be screened again to remove fine powder or oversized pellets to improve the product quality.

Packing equipment:

quick pellet packing scale, weighing rage 20-50kg/bag, 4-6bags /min.

Auxiliary process: dust collection system can improve the work condition, the oil adding system and water adding system can improve the feed palatability.

|

The main equipment section |

|

Number |

Description and type |

Qty |

Picture |

|

1 |

RM receiving and cleaning process:

SCY80 cleaner

Granule precleaner SCY80, output 20-30t/h, podwer

cleaner SQLZ60X50X100, output 10-15t/h

|

1 |

|

|

2 |

First grinding process:

hammer millSFSP668×600

55KW, output 5-7t/h

|

1 |

|

|

3 |

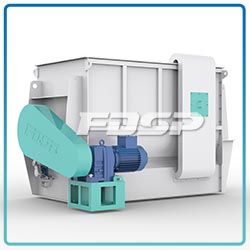

First batching and mixing process:

Mixing machine: mixer SLHY1,11kw, 500kg/P, output: 3-6t/h, homogeneity CV≤7%

|

1 |

|

|

4 |

Micro-grinding process:

Pulverizer: SWFL110,110+11+2.2KW;output:2-4T/H

|

1 |

|

|

5 |

Second mixing process:

Mixing machine: Mixer SHSJ1,11KW,500kg/P, output: 3-6t/h, homogeneity CV≤5%

|

1 |

|

|

6 |

Pelleting Process:

Pellet mill SZLH420x with 45*2KW, output for shrimp feed:1.5-2.5t/h.

|

1 |

|

The process can be optimized according to different customer needs:

1. Single point dust collection mode is used in the plan which means pulse filter is equipped for every rotary distributor(mesh) and granule cleaner with good effect. Single point dust collection is kind of humanized design of our company, to provide a better working environment, but the cost increases, customers can consider whether it is needed in actual situation;

2. The quantity of bins can be adjusted to achieve the beast use ratio and effectively control the production cost based on factors such as customers' formula, characteristics of raw materials.

3.the second mixing in this process adopt non-automatic batch type mixing process, it has less cost for equipment, the customer also can choose full automatic batching system with larger cost but also higher efficiency.

4.We did not consider drying process here, if there is need to produce large crab pellet feed, we can add vertical dryer under stabilizer which can reduce the moisture of pellets to ensure the pellet quality.

5.Seedling shrimp and crab feed process is not considered in this process, it can also be added according to customer's demand.