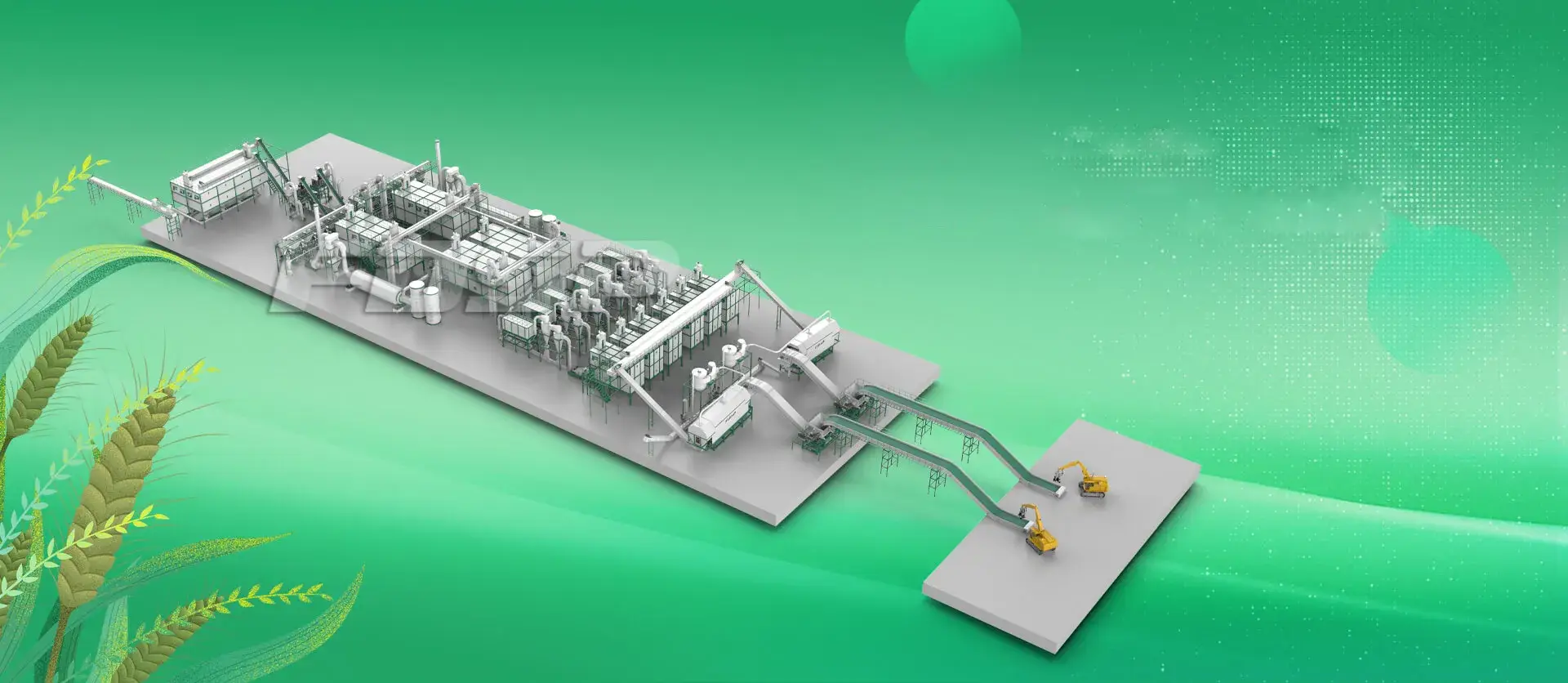

Environmental Methanol Straw Particle Process

New Ecological Clean Energy · Biomass Raw Material Pretreatment Particle Forming Equipment and Engineering

Environmental Methanol Pellet Project

Environmental methanol is a new clean energy source primarily obtained through various methods such as biomass energy, environmental hydrogen with CO₂ capture, and renewable energy sources, resulting in near-zero or very low carbon emissions during production. Using biomass materials, like straw, which are preprocessed into pellet or block products, the material undergoes a gasification reaction under high temperature and pressure. This process converts the solid feedstock into a gaseous product, which then, through pyrolysis technology, produces synthetic gases like methane, carbon monoxide, carbon dioxide, and hydrogen. These gases are mixed with an appropriate catalyst and a certain amount of steam, initiating a synthesis reaction at an optimal temperature to generate environmental bio-methanol fuel. Biomass pellet preparation from raw materials like straw is a vital step in this production process.

With continuous advancements in environmental methanol production technology and reductions in costs, its applications are expanding, making environmental methanol an indispensable part of the global new energy market. This is seen as a key pathway for achieving global carbon neutrality and peak carbon goals, with immense potential and investment prospects, prompting nations and major companies to take the lead in securing their positions in this new energy frontier.

- Adapting to energy transition trends

- Mitigating energy pressures

- Promoting industrial upgrades

- Improving energy utilization efficiency

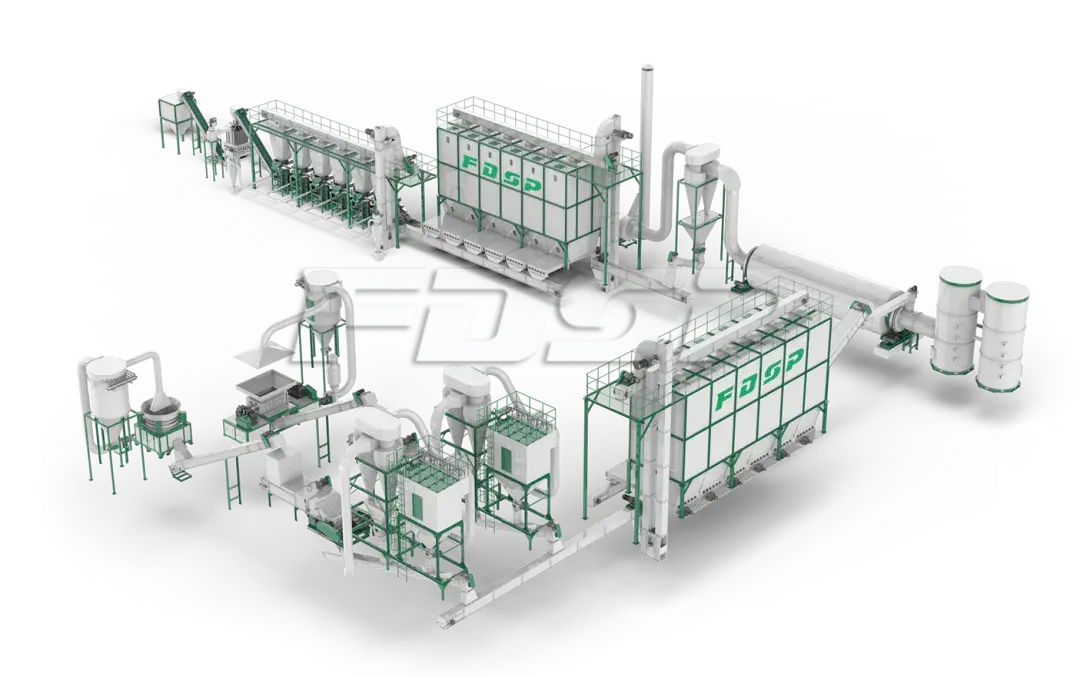

Process Description

Process description for preparing biomass pellets from materials like straw

Crushing Section

A grab loader feeds straw into a dual-shaft shredder, where the material undergoes crushing through a combination of shearing, tearing, and compressing, achieving the required size for further pulverization.

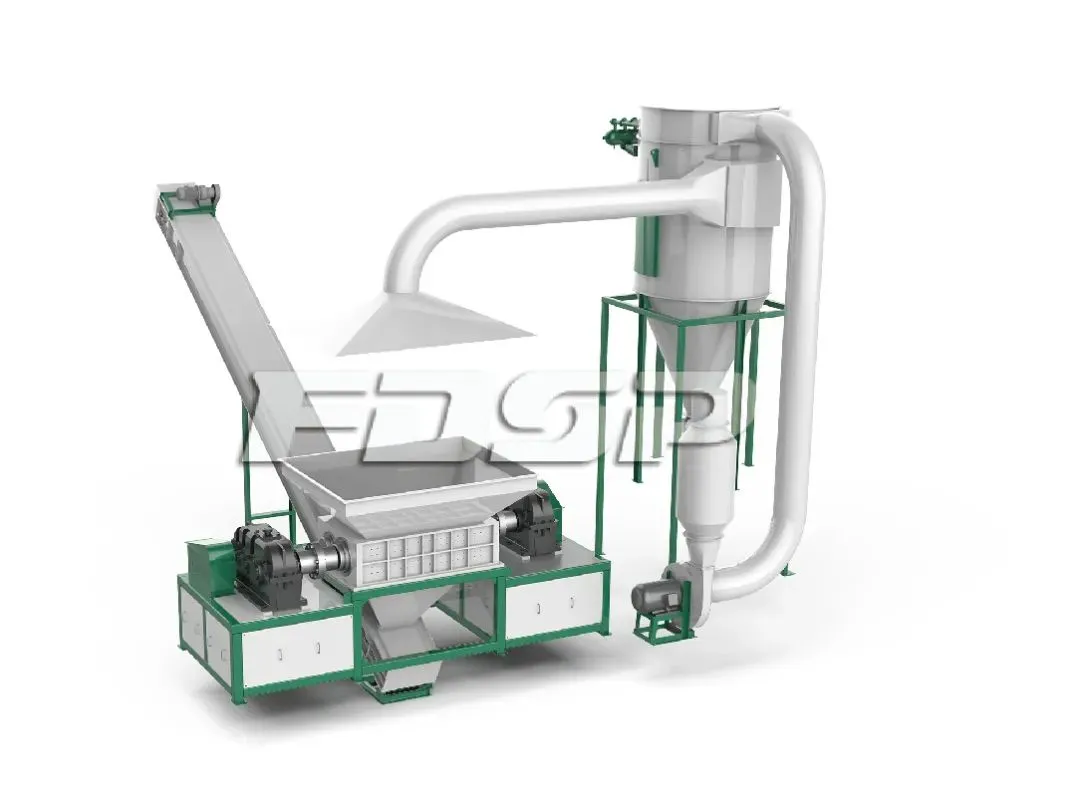

Grinding Section

The crushed material is transported via a conveyor belt equipped with a magnetic separator to remove any metal impurities. The grinding system, designed by FDSP, includes a dedicated double-rotor pulverizer for straw and an air network system. The pulverizer’s internal blades tear and strike the material, preparing it for subsequent pelletizing or compacting. This section supports sealed transportation, negative pressure dust reduction, and clean production.

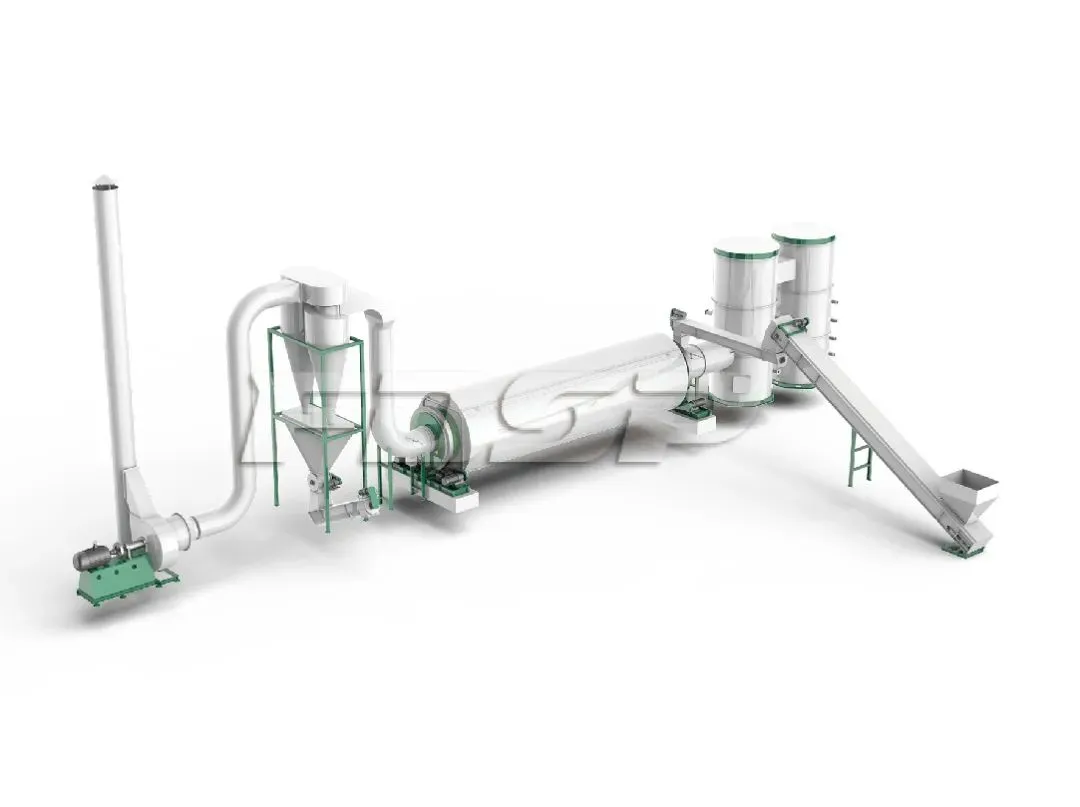

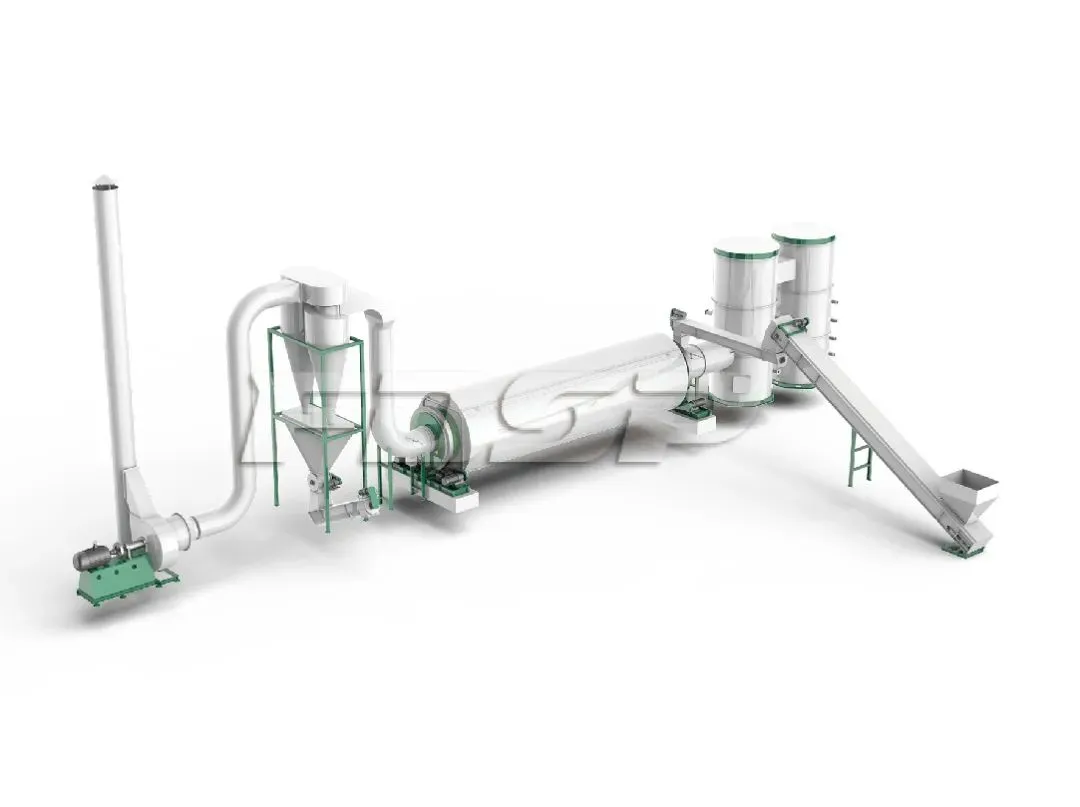

Drying Section (Optional)

Materials for pelletizing must have a moisture content below 20%. If the pulverized material’s moisture is too high, it is blended with dry material to lower the average moisture or dried using a dryer. This section uses a triple-pass drum dryer, extending the contact time between the material and hot air, significantly reducing the dryer’s length and footprint. The fuel can be agricultural or forestry waste, or scrap or pellets from the production line, burned in a specially designed combustion furnace. The direct-flame hot air, which doesn’t require heat exchange, directly contacts the wet material, achieving higher drying efficiency.

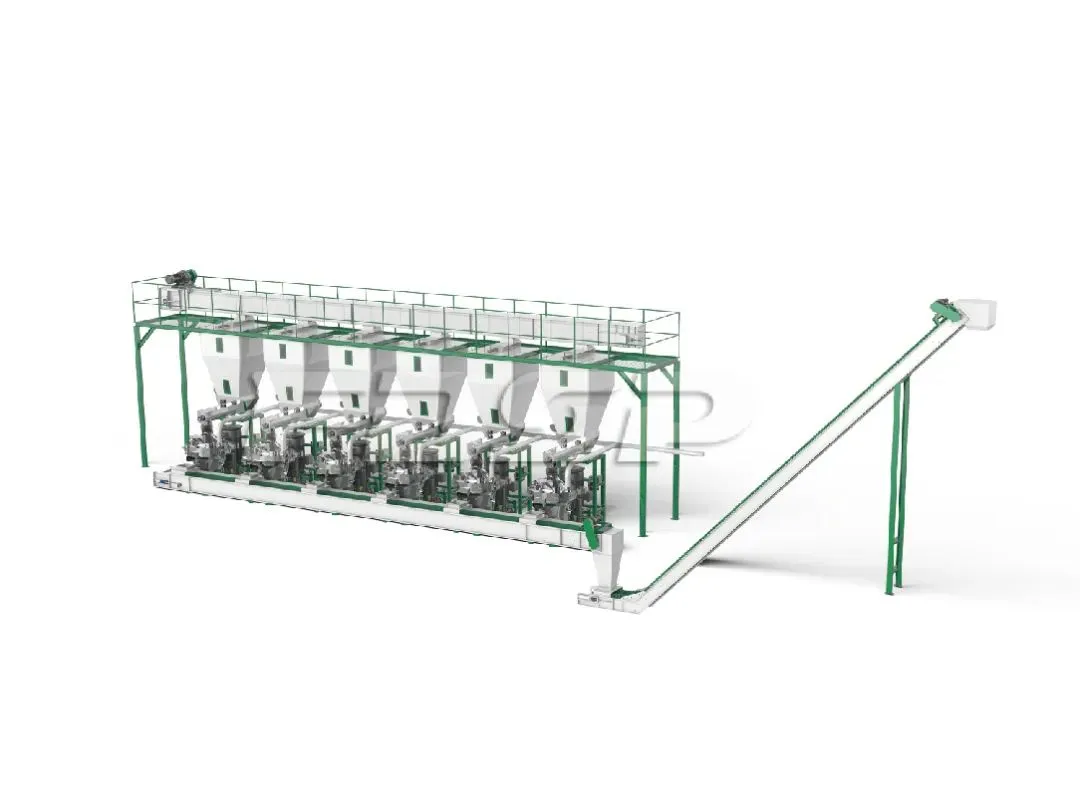

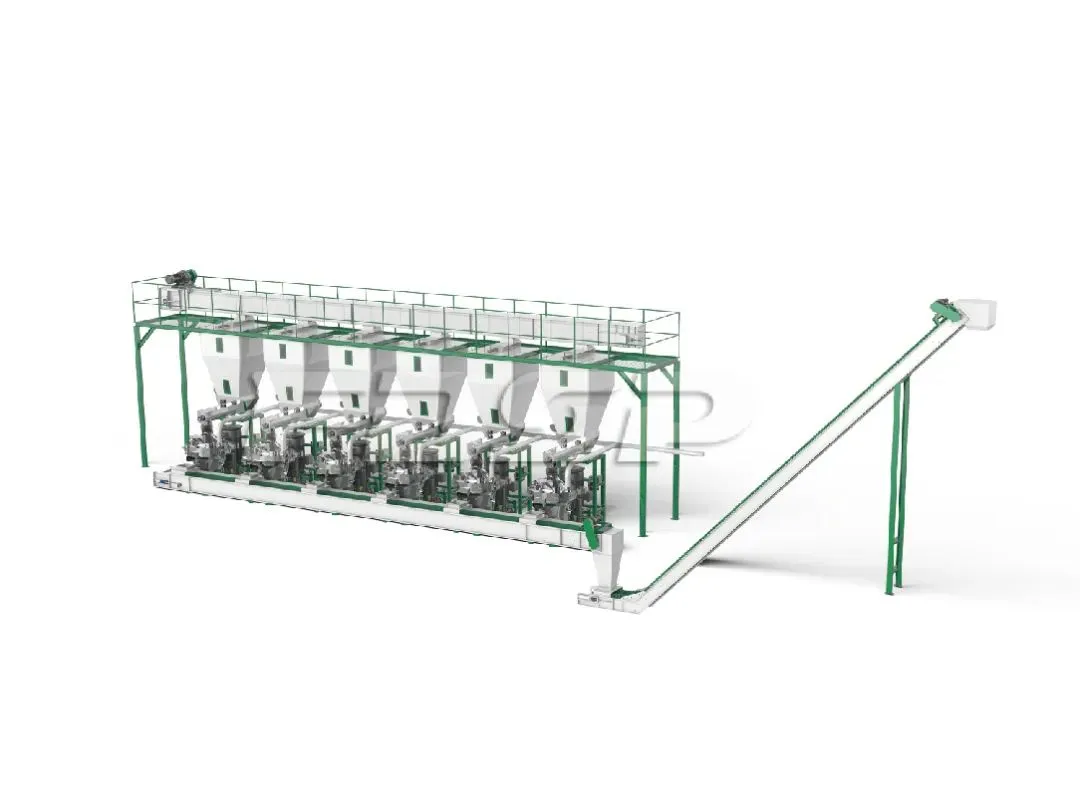

Pelletizing/Compacting Section

Materials meeting the moisture (below 20%) and fineness requirements are transported to the pelletizer or compactor. Through mechanical extrusion, the material is processed into cylindrical pellets or square/round blocks to meet the demands of subsequent pyrolysis gasification.

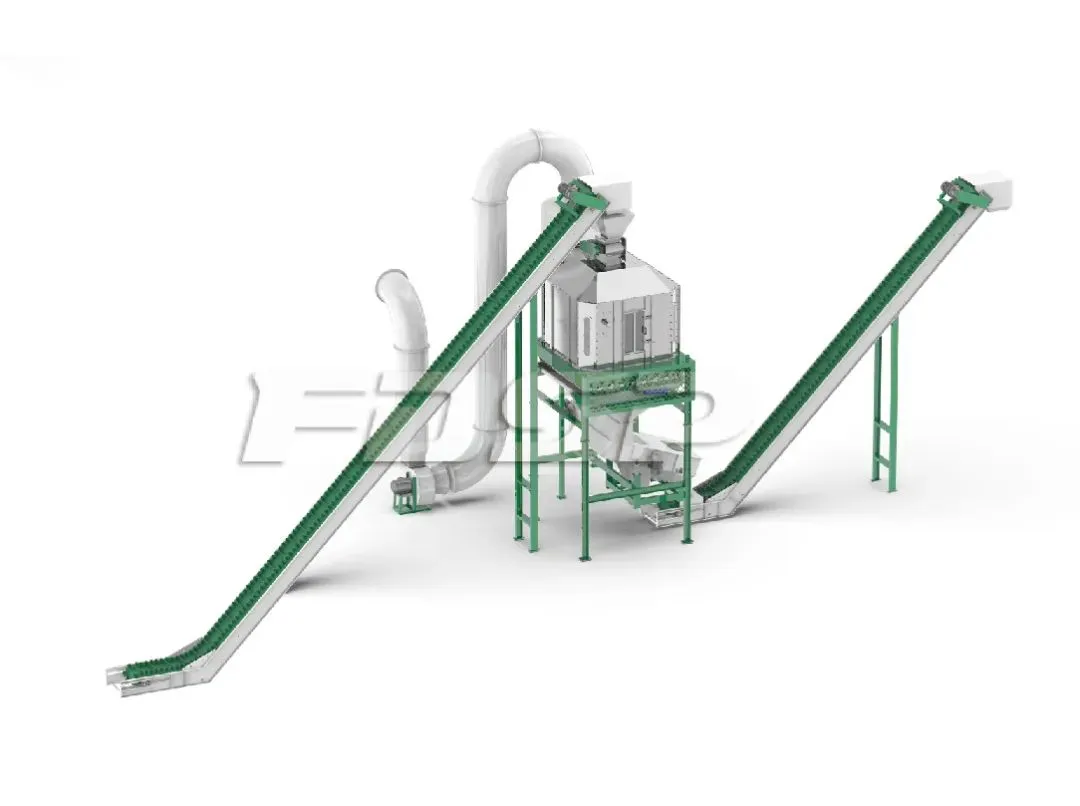

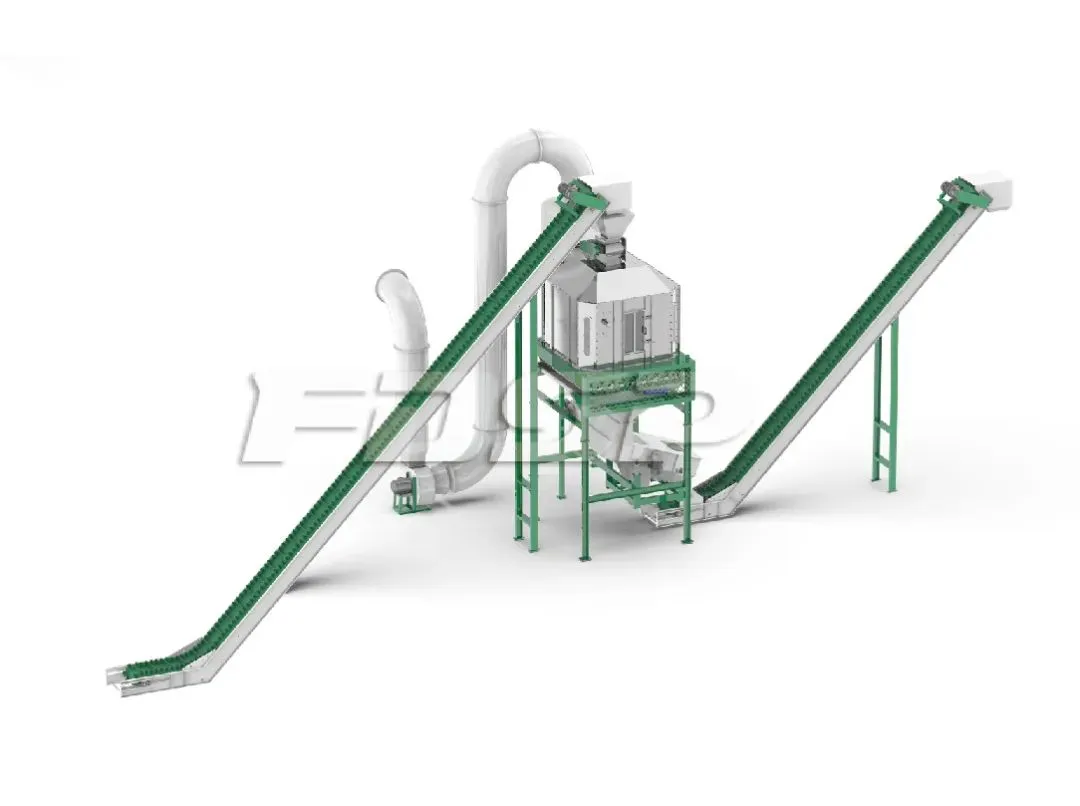

Cooling and Screening Section (Optional)

After pelletizing or compacting, the material surface temperature can reach 70-90°C. Direct bagging could cause the pellets/blocks to absorb moisture from the surrounding air, leading to swelling, surface cracking, or even fracturing. Forced air cooling quickly cools the material to prevent cracking, and screening removes debris from the final pellet or block products.

As a leading pelletizing system integration service provider, FDSP has proactively tailored its offerings to the demands of straw-based environmental methanol projects, with a focus on critical steps like straw raw material pre-processing and pellet forming equipment and engineering. We have developed and upgraded specialized equipment such as straw shredders, rotary cutters, double-rotor pulverizers, dryers, pelletizers (compactors), cooling, and screening equipment. Our offerings include end-to-end services, from process design, manufacturing, installation, commissioning to personnel training and operational support.

In the future, FDSP will remain dedicated to innovation in technology and equipment for biomass-based environmental methanol production, providing more efficient, eco-friendly, and energy-saving system solutions to help achieve global carbon neutrality and sustainable development goals as soon as possible.

Send Inquiry

Get a quote, Learn more about products