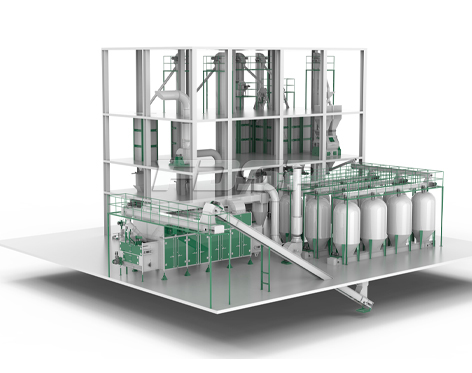

Section introduction:

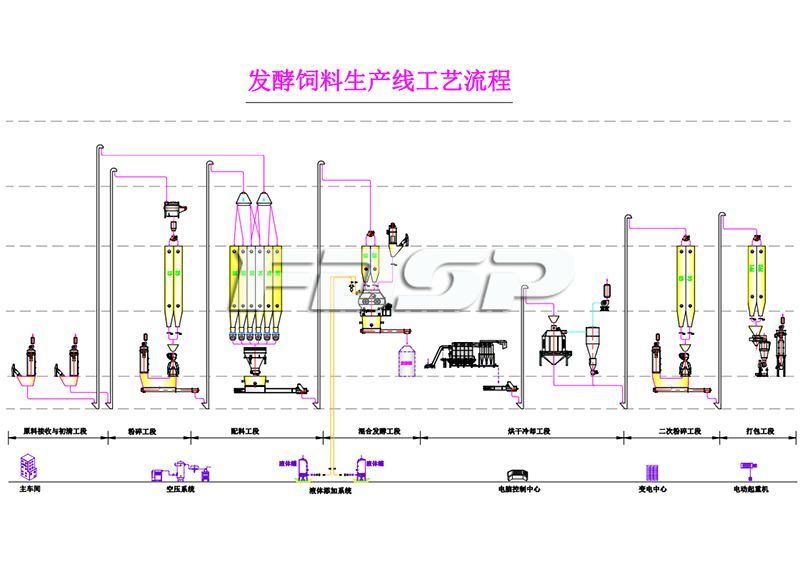

(1) Raw material receiving section

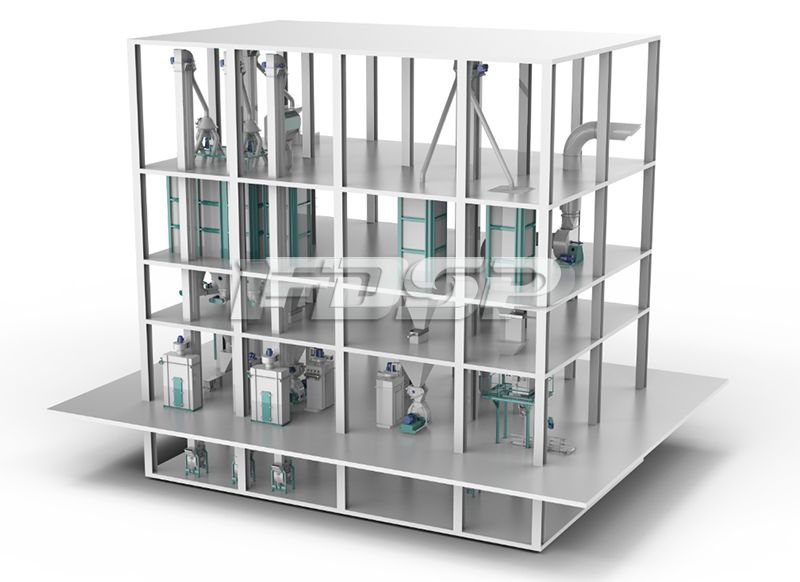

Raw materials which needs to be crushed and the powdered raw materials enter the production line through two independent blanking ports. Two sets of independent dust removal systems are adopted to avoid cross pollution caused by centralized dust removal. Granular raw materials enter the bin to be crushed for crushing, and powdery raw materials directly enter the batching bin for batching.

(2) Crushing section

Adopting a tear circle hammer mill machine, SFSP668x1000 (160kW), two bins which waiting for crushing can store two different raw materials. When changing varieties, the no-load time of the crusher can be reduced and the crushing efficiency can be improved.

(3) Batching section

Due to the small variety of fermented feed raw materials, the project designs 6 batching silos and a set of 2 tons/batch batching scales. The batching accuracy can reach static 0.1% and dynamic 0.3%.

(4) Mixed fermentation section

The mixed materials are lifted into the mixer for mixing. The upper part of the mixer adopts an independent micro addition port and is equipped with a dust removal device. At the same time, the liquid addition system can quantitatively add bacterial liquid and water to the mixer for mixing with other materials. The mixed materials enter the fermentation tank, fermentation pool or fermentation trolley for fermentation (the specific fermentation container can be configured according to customer requirements).

(5) Drying and cooling section

The fermented materials have high moisture content and need special drying equipment for drying. The dryer needs to be dried at low temperature to avoid high temperature failure of bacteria. The dried materials are cooled by a set of SKLB8 pendulum cooler, fed evenly by impeller, 4-72no8c, 30kW cooling fan.

(6) Secondary crushing section

After fermentation and drying, the materials are crushed again to meet the fineness requirements of customers.

(7) Packaging section

A set of auger packing system, feeding large and small augers with two speed motor, automatic weighing, automatic zero clearing, automatic alarm, automatic accumulation and printing records, weighing accuracy ± 0.2%; The bag sewing conveyor adopts Hebei Qinggong bag sewing machine head, which has the functions of automatic oiling, internal cutting and automatic cutting. In addition, it can be independently equipped with a folding machine or a heat sealing machine according to the requirements of customers for packaging bags.

(8) Auxiliary section

The packing system is equipped with an independent dust removal system, and the air volume can be adjusted by manually adjusting the valve; Two sets of liquid adding systems are equipped with air compression system to provide air source for various pneumatic components.

According to the needs of different customers, the scheme can optimize the configuration:

1、The number of silos can also be adjusted according to the customer's formula, the characteristics of raw materials and other factors to achieve the highest utilization rate and effectively control the production cost;

2、The project adopts the automatic batching process. If the output is small, also can use the manual batching process;

3、If there is no high requirement for the fineness of finished products after drying and cooling, the grinding section after cooling can also be removed.