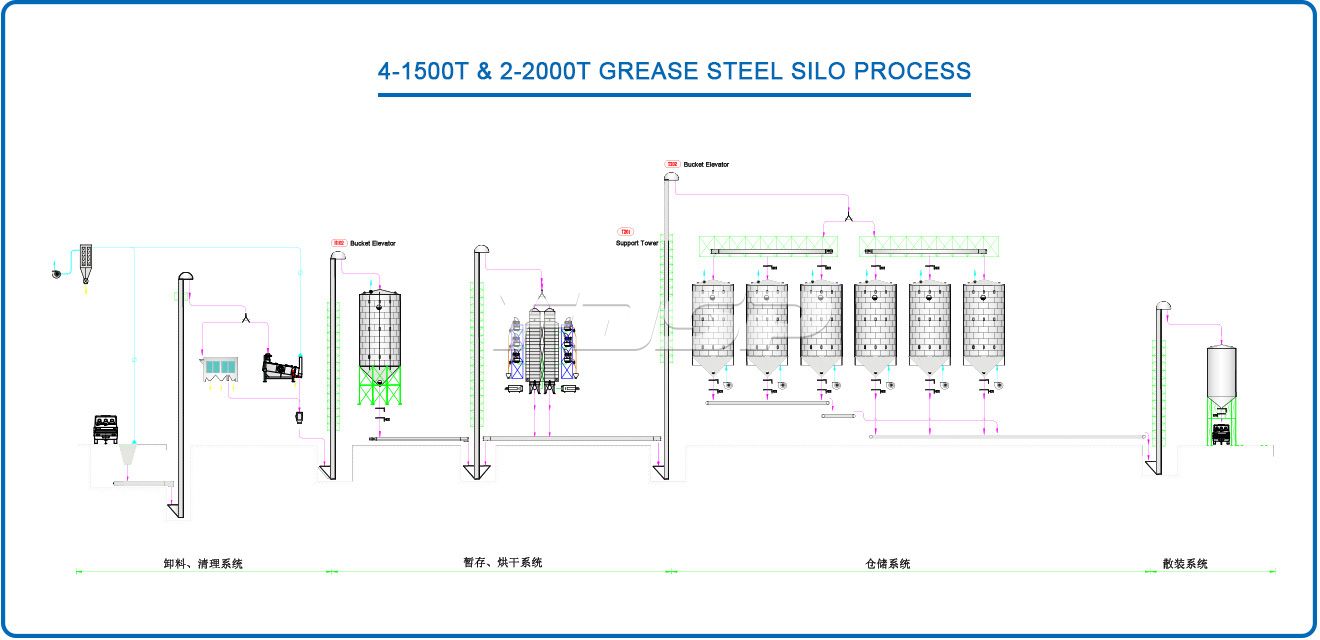

Project Description:

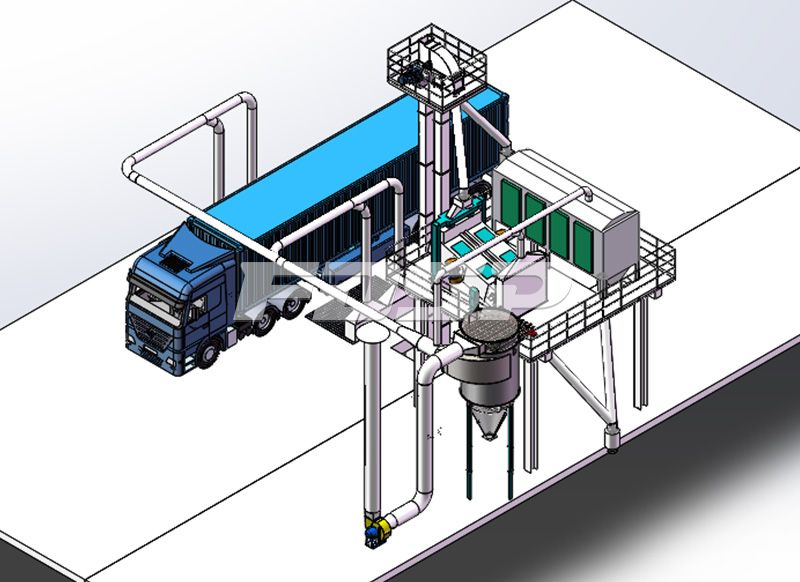

1) unloading process is double side loading, the grizzly can carry the truck, two sided of dumping hoper is equipped with de-dusting system to improve the working condition.

2) cleaning process is equipped with double drum cleaner and tubular magnet with large capacity 80TPH

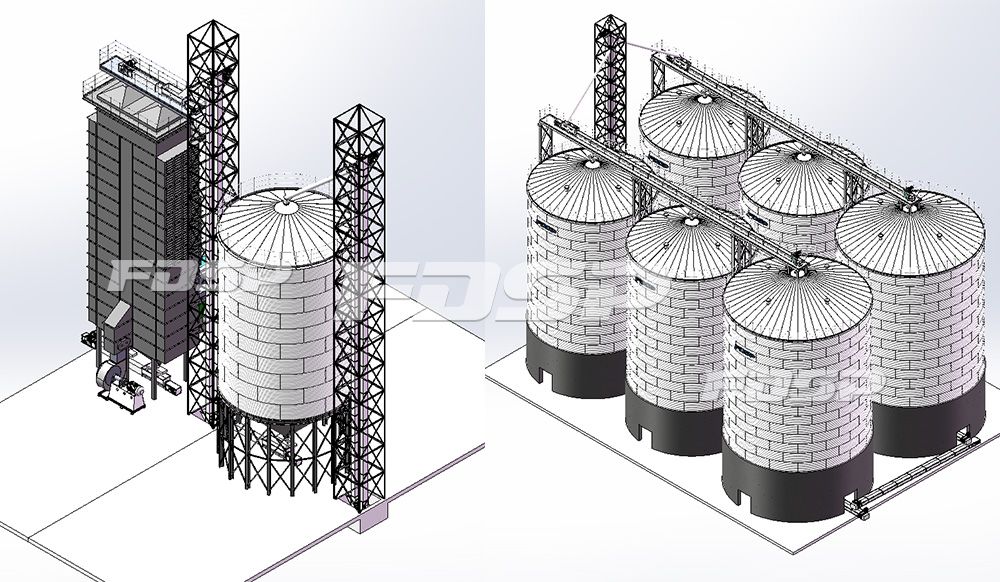

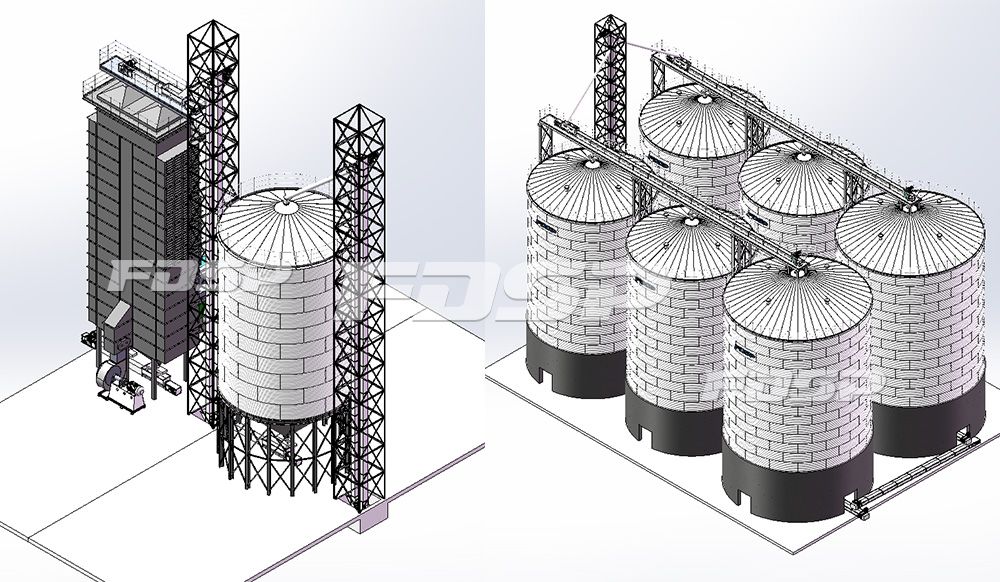

3) buffering and drying process: 1-500T bolt silo is for buffering, it will be a buffer for the speed difference between inlet and drying to reach the goal of quick loading, even drying.

4) storage process is 4-1500T&2-2000T bolt silo: the capacity for inlet is 40TPH, there is temperature measuring and ventilation system inside the silo which could control the grain condition.

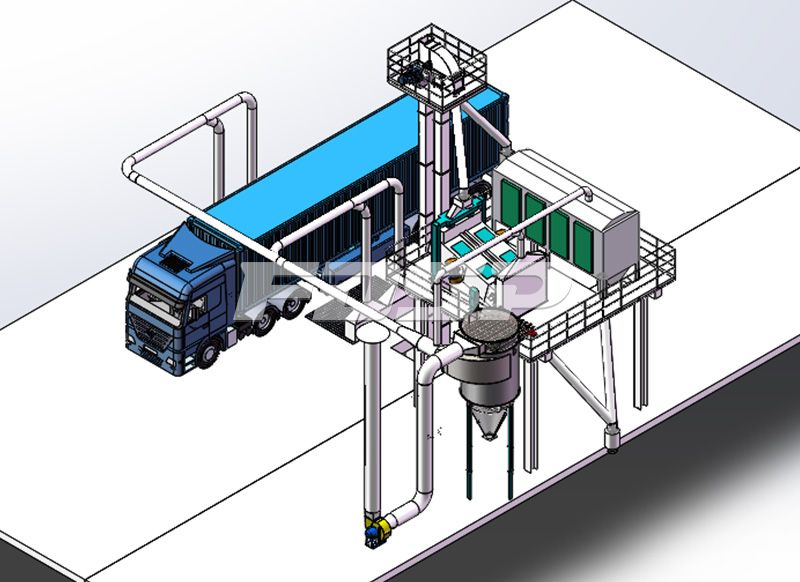

5) bulk process: equipped with 1-75T soybean bolt silo, truck could pass and discharge through the bottom.

Features of the engineering process design:

(1) equipped with double drum cleaner specially used for cleaning maize and soybean, and also vibration screener for rapeseeds;

(2) When design the silo, the ventilation screen is designed to be detachable and easy to replace, so as to keep the air duct unobstructed and the good ventilation effect, effectively control the grain situation in the silo;

(3) the silo base is designed as concrete cone hopper type, the material can be discharged as their own gravity which can save equipment and power.

Other instructions:

For different projects and different customer requirements, the process will be also different, the following could be options during the process design:

(1) cleaning system (this part can be removed if the raw materials are clean);

(2) ventilation and temperature measuring system (if the raw materials are relatively dry, and the storage time in the silo is less than 7 days in winter and less than 4 days in summer, this part can be removed);

(3) the cone hopper could also be concrete flat bottom, then the discharging could choose sweep auger based on customer's need.

(4) the silo changing system (if the raw material is dry and storage time in the silo exceeds 60 days in winter and 30 days in summer, the silo changing system shall be considered);

(5) customers can choose helix silo or bolt silo according to their own needs.