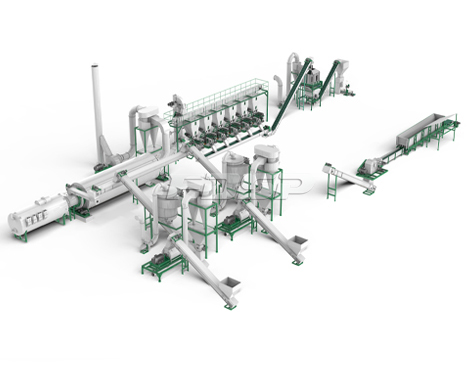

5-7tph wood logs pelleting line

Using logs as raw materials, formed by solidifying and extruding into high-density pellet fuel through pretreatment and processing. It can save energy and reduce emissions, will make good economic and social benefits. It can be widely used in biomass power plants, biomass steam boilers, household fireplaces, drying stove and biomass gasifier, etc, is an efficient and clean renewable energy source.

Jiangsu Liangyou Zhengda Co., Ltd. specializes in the production of complete biomass pellet fuel forming equipment, can provide customers with logs, wood chips, shavings and other raw materials of biomass pellet production line; Biomass granulation production line with building template, woodworking scrap and other raw materials; Complete biomass pelleting production line with corn straw, wheat straw and straw grass as raw materials; Complete biomass pelleting production line with fruit shell, fruit residue and palm as raw materials; Complete biomass pelleting production line with crop waste, sludge, coal and other raw materials, tailor-made complete equipment solutions for customers, to meet the different needs of customers.

Now take the production line project of 5-7tph wood logs pelleting line as a case, according to the technological process and each section to do the following introduction and explanation.

Raw Material:

There are mainly logs of pines, firs, acacia trees, beech trees, eucalyptus trees and other trees.

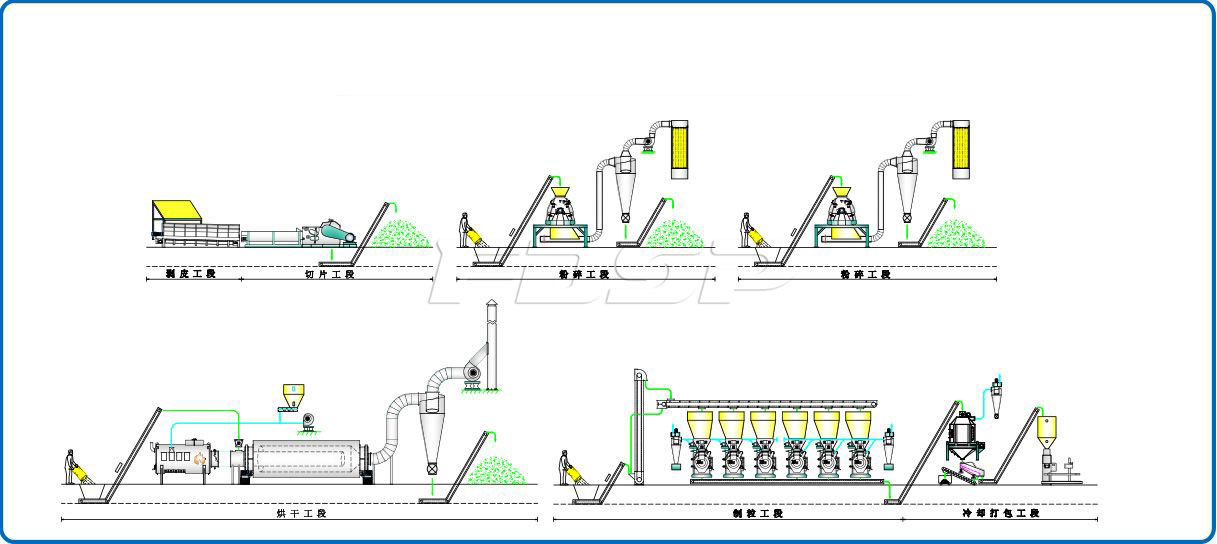

Craft procedure drawing:

Flow process of log pelleting complete project

Debarking Process---Chipping Process--Grinding Process--Drying Process--Pelleting Process--Cooling&Bagging Process

Introduction to flow diagram:

After debarking the branches and trunks of logs, the logs are cut into small chips by the chipper. The size of the chips is 20-30mm and the thickness is about 3mm, then be finegrinded into sawdust of 3-4mm by the hammer mill; next the raw material with 40% moisture is dried to about 15% through a three-layers drum dryer; finally is pelleted, the diameter of finished pellets is 6-10mm for choosing. After pelleting and cooling, it is packed into 20-50kg/ bag by small bag packing scale for convenient transportation and sale. The capacity of log pellet complete project is 6 tons of biomass pellets, the total power of whole line equipment is about 1250 kw, and the plant covers an area of 3000 ㎡, including raw material storage and finished product storage. The whole line’s design is compact, the structure is reasonable, meets the requirements of environmental protection, and can be directed designed according to customers’ requirements.

Introduction to Process:

Debarking Process

Raw material debarking can improve heat value of finished pellets, reduce ash residue after combustion of finished pellets and reduce emissions.

Debarking Machine: LYMB-1200, length is12m, power is 30kw, disigned capacity is 10tph.

Chipping Process

The chipping process of the log pellet complete project is to process the wood logs into wood chips, the size is 20-30mm, the thickness is about 5-10mm, and then enter the processing of the following sections.

Chipping Machine: Chipper LYGX218D, power of main motor is 132kw, feeding roller is 4kw, oil pump is 0.55kw, designed capacity is 38m³.

Grinding Process

This process is without dust discharge. After grinding by hammer mill, the sawdust is pneumatic transported out of the fan by negative pressure suction.The hammer mill is of tear circle structure with high grinding efficiency.The rotor can be operated in a positive and negative way to increase the service life of the hammer blade.The motor adopts the direct transmission of motor.

Grinding Machine(2sets): MFSP68*120, power is 160kw, capacity is 6-8t /H (moisture of raw material is 40% ).

Drying Process

Three - layer drum dryer, after drying wood chip moisture in about 13-18%.

Drying equipment: LYHG60, drum diameter 3.45m, length 11.6m, power 22kw, design with 6T/H output(moisture of raw material is 40% )

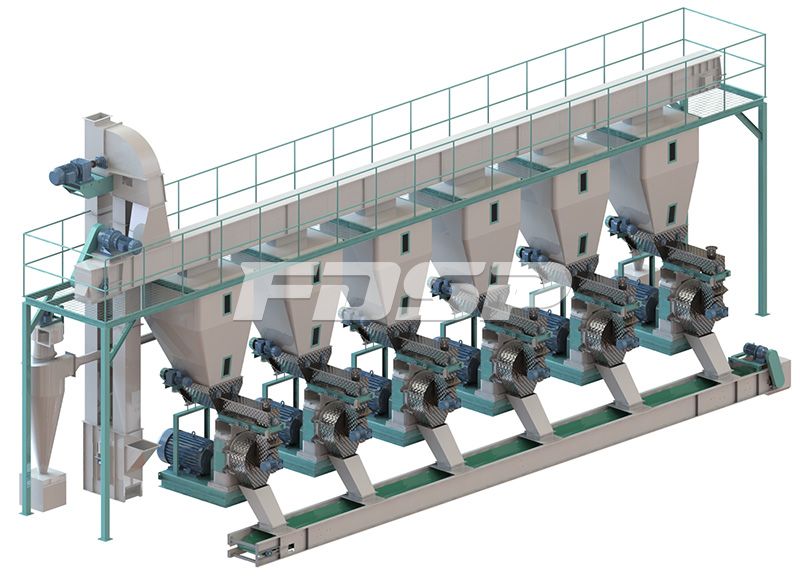

Pelleting Process

The diameter of biomass pellets is 6-10mm, and the biomass pellets have the characteristics of high calorific value, no pollution and low ash content, which can be widely used in biomass power plants, biomass steam boilers, household fireplaces, drying stove and biomass gasifier,etc.

Pelleting Machine(6sets): MZLH420, power of main motor is 90kw, power of forced feeder is 0.75kw, the designed capacity is 1 ton per unit.

Cooling & Bagging Process

The cooling process of the log pellet complete project use cooler to reduce the pellets temperature and decrease pellets moisture, low energy consumption, easy operation, high level of automation, after cooling through the cooler, the pellets temperature generally is not higher than room temperature 5℃, the moisture is about 8-10%, the density of pellets is 650-750 kg/m³.

Packing scale: according to the local sales demand of the customer, choose the suitable packing scale to facilitate the customer to sell products. There are usually two specifications: small bag and ton bag. The packing specification of small bag packaging scale is 20-50kg/ bag, and the ton bag scale is 500-1000kg/ bag.

Cooling machine: MKLB4, the volume of the cooling chamber is 4m³, and the designed capacity is 5-7 tons per hour.

Packing machine: MDBLY-K, the packing specification is 20-50kg/ bag, and the packing speed is 3-5 bags/minute.

According to the needs of different customers, the scheme can be optimized:

1. If necessary, buffer bins can be added between each section to replace the storage yard. The advantage is that it can improve the automation degree of production line and reduce dust pollution in the workshop; The disadvantage is that it will increase the construction cost of the production line, and because the bulk density of materials after crushing is very light, it is easy to bridge in the bins and material does not drop.

2. The packaging equipment can be adjusted according to customers' requirements for finished product packaging. It can also be stored in bulk or stored into silos.