3-6T/H Extruding Aqua Feed Mill Plant

Producing extruding feeds by extrusion technology has become a trend of aquatic feed processing technology. The unique function of extruder machine is to change the weight of feed, to make floating, slow-sinking and sinking extruded fish feed. The floating fish feed not only can improve feed efficiency, but the important thing is that the farmer can see the situation of fish eating, which can avoid overfed and reduce feed waste.

Jiangsu Liangyou Zhengda Co., Ltd., specializing in the production of feed machinery and engineering, can provide customers with complete sets of equipment solutions for livestock feed (pig, etc.), poultry feed (chicken, duck, goose,etc.), ruminant feed (cattle, sheep, etc.), common aquatic feed (four major Chinese carps, etc.), special aquatic feed (shrimp, crab, etc.), extruded aquatic feed (floating and sink fish feed, shrimp feed, etc.), premix feed (including all kinds of additives, etc.), and pet food(cat food, dog food, etc.). to meet the different needs of customers.

Now take the 3-6tph extruded aqua feed production line as a case, according to the process flow and each section to do the following introduction and description.

Raw Materials:

The main raw materials of floating fish feed are protein, it consist of grain, bread meal, rice bran, bran, blood meal, oil, premix feed, etc.

Introduction of Main Process:

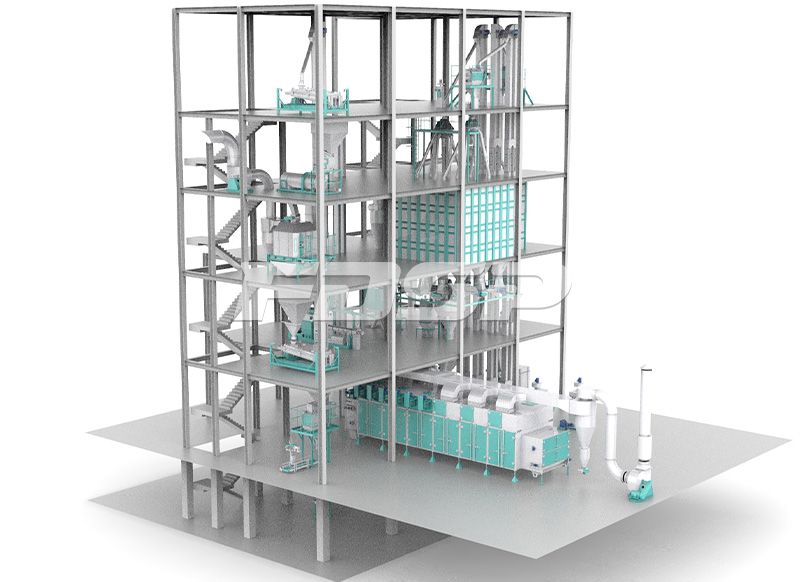

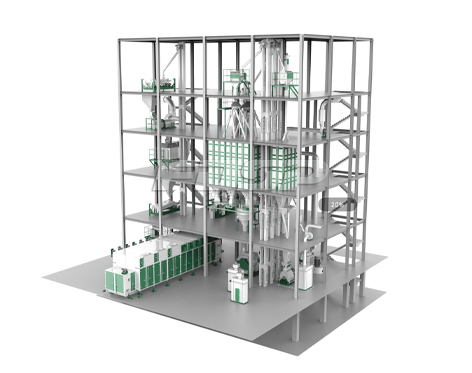

The features of extruding fish feeds are that the crush fineness is small (about 60-100 mesh), the curing degree is high, with high oil content (The refueling way is the combination of mixer, extruder and coating three ways), the diameter size of finish pellets is large (about 0.6-20mm). This extruding fish feed mill plant’s capacity is designed to be 3-tph, adopting one grinding process, first dosing & mixing process, one pulverizing system, second mixing process, one extruding process, one coating & bagging process. The total power of this line is about 450kw, the working land size is about 30*24*30m, and matching 2ton boiler. The whole line has compact design, reasonable structure and meets the requirement of environmental protection. It can be customized according to customer’s requirements.

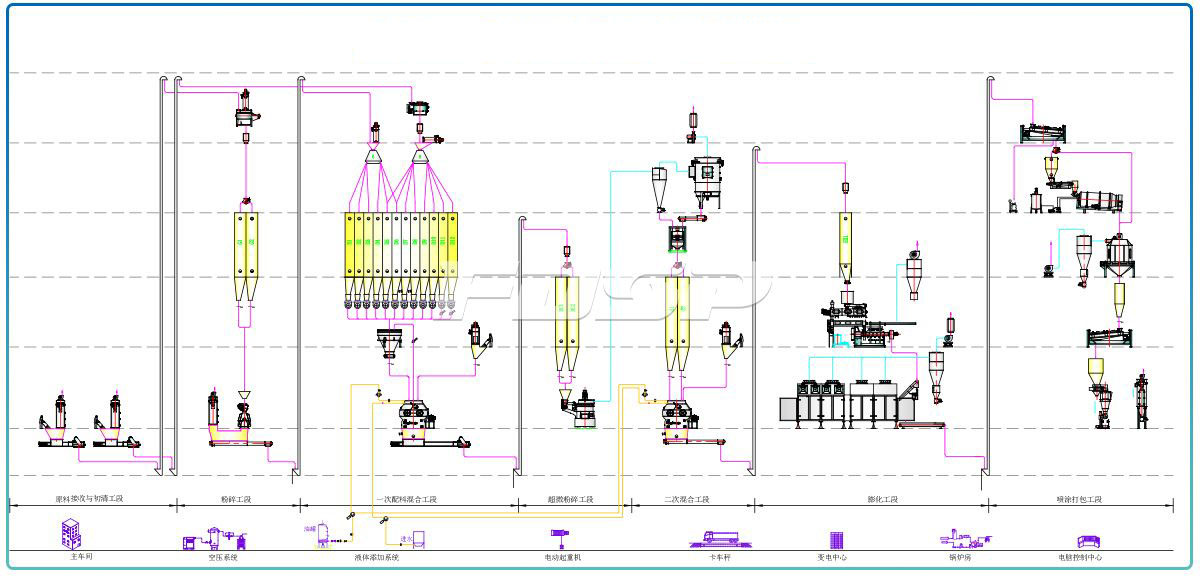

Flow Diagram of Process:

RM Receiving & Precleaning System—Grinding System—First Dosing & Mixing System—Pulverizing System—Second Mixing Sytem—Extruding System—Coating & Bagging System

Craft features and illustration of Each Process:

Raw materials receiving and cleaning section:

In this section, pellet feeding cleaning and powder feeding cleaning are separated independently and separate dust removal. Dust removal effect is good.

Cleaning equipment:granules sifter SCY80,capacity 20-30T/H;powder sifter SQLZ60X50X100, capacity 10-15T/H.

First coarse grinding section:

This section adopts one hammer mill, and with two pre-grinding bins. The crushed varieties can be changed alternately. Before entering the bins, the impurities are removed by magnetic separation device to ensure the safe operation of the hammer mill.

Grinding equipment : Hammer mill SFSP668×600, 55kw, designed to produce 5-7t /h

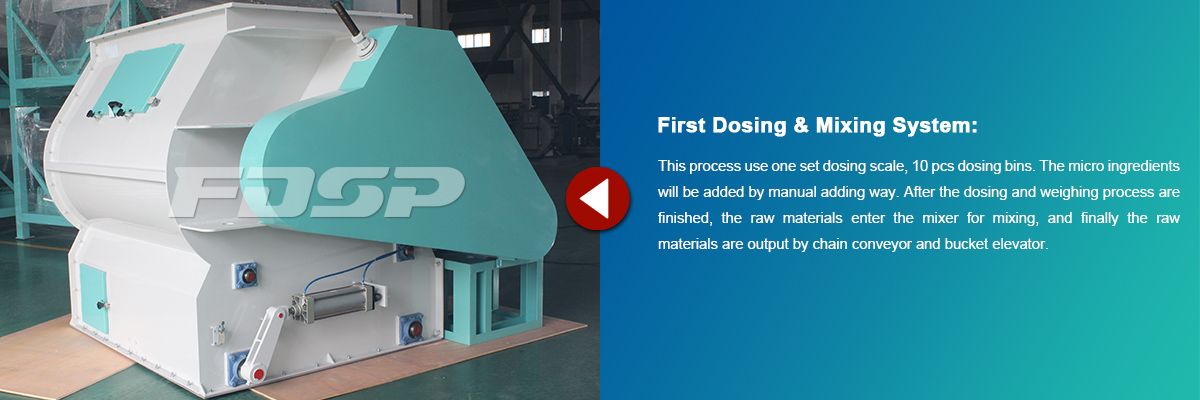

First Dosing & Mixing System:

This section adopts 12 batching bins, one set of batching system. It is controlled by the batching program independently developed by our company to realize accurate fast and slow feeding, fast batching and high precision.

Weighing equipment: Dosing scale PCS10, dosing precision: dynamic ≤3‰, static ≤1‰.

Mixing equipment: mixer SHSJ2, (18.5KW, 1000kg/ batch), designed to produce 8-10t /h/ set. Mixture uniformity CV ≤5%.

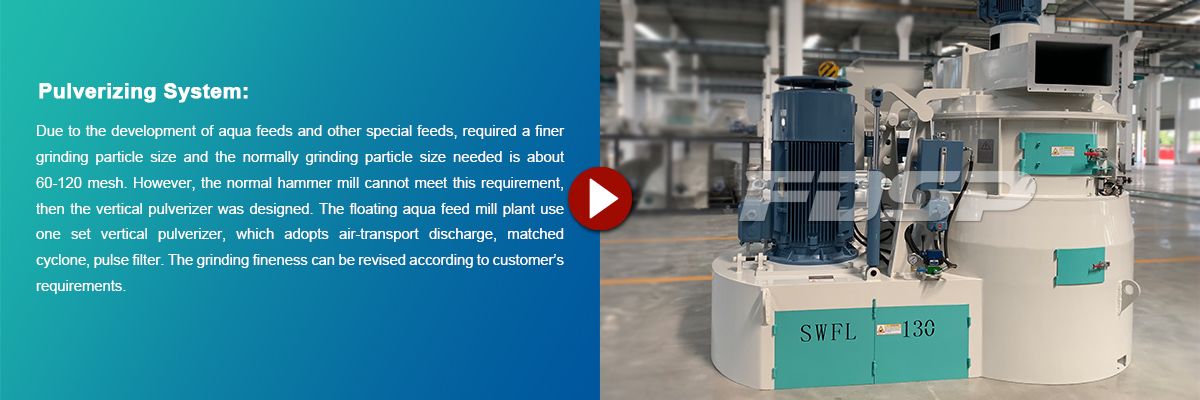

Micro grinding section:

Due to the extruder high requirement for the fineness of raw material, generally 60-120 mesh, this section adopts a pulverizer, equipped with two pre-grinding bins. They can take turns to store and discharge the material, which reduces the pulverizer idle time. It adopts the wind type discharging, is allocated with cyclone, pulse filter, and the grinding fineness can be adjusted.

Pulverizer equipment: SWFL130, 160+15+ 2.2kw; Design time: 3-6t /h.

Second mixing section:

This section adopts two secondary mixing bins, a mixing machine and a micro element adding port.

Mixing equipment: mixer SHSJ2, 18.5kw, 1000kg/P, designed to produce 8-10t /h. Mixture uniformity CV≤5%.

Extruding System:

This section adopts a single screw extruder, equipped with a pre-extruding bin above the extruder. The extruding bin is designed as a round bin, and equipped with a disk-type feeder to prevent material from forming and discharge smoothly.

Extruding equipment: SPHS165, 2.2+18.5+160+ 5.5kw, design output: 3-6T /H (discharging hole diameter 4.0mm), drying equipment: SHGW240×2-6, 0.55+1.5*2+7.5×8+ 0.55kw, design output: 4-6T/H

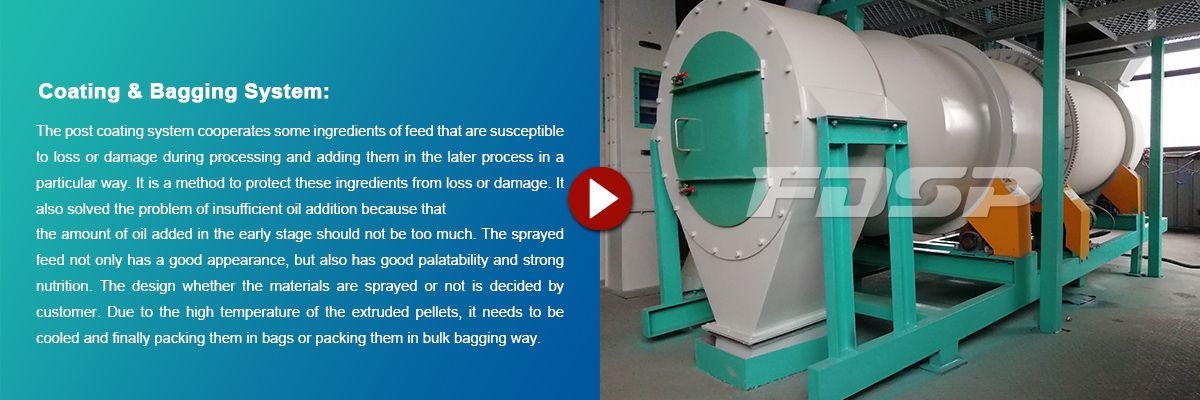

Coating & Bagging section:

This section adopts a set of roller grease coating equipment, equipped with pneumatic gravity diverter before entering the equipment. You can choose whether to spray finished pellets according to different formula requirements. The coating section solves the problem that the early phase of the material fat content should not be too much and then can not meet the fat content requirements. By coating, the feed appearance is good, palatability is strong, nutrition is strong. The materials after oil injection are screened and packed after cooling by cooler.

Coating machine: SYPG1000, 2.2kw, design output: 4-6T/H,

Swing cooler: SKLB4, 1.1+ 1.5kw, 4m3 volume, design output: 6-8T/H.

Packing equipment: Rapid single-bucket granule scale for extruding material, packing range: 20-25kg/bag, 4-6 bags/minute.

Auxiliary section:

The dust removal system: it is used in the bagging system which can improving the working environment for workers; Oil adding system and Water adding system: it can improve the feed palatability.

According to the needs of different customers, the scheme can be optimized:

1. The scheme adopts the single-point dust removal mode, that is, each rotary distributor (powder material) and pellet cleaner is equipped with a pulse dust filter, which has a good dust removal effect. Single point of dust removal is our company’s humanized design, which can provide a better working environment, but the cost increases. Customers can consider whether to use this configuration according to the actual needs;

2. The quantity of bins can also be adjusted according to the formula of customers, the characteristics of raw materials and other factors, so as to achieve the highest utilization rate and effectively control the production cost;

3. Assembly or welding can also be adopted for the installation of the bin. The assembly bin has a high cost, quick and convenient on-site installation, and the welding silo has a low cost. On-site welding by workers is with high labor intensity and long time. Users can make reasonable choices according to their own needs;

4. In this project, the secondary mixing adopts the process of non-automatic batching by batch, with less equipment input. Users can also adopt the process of automatic batching, with a large increase in equipment input, but efficiency increased.