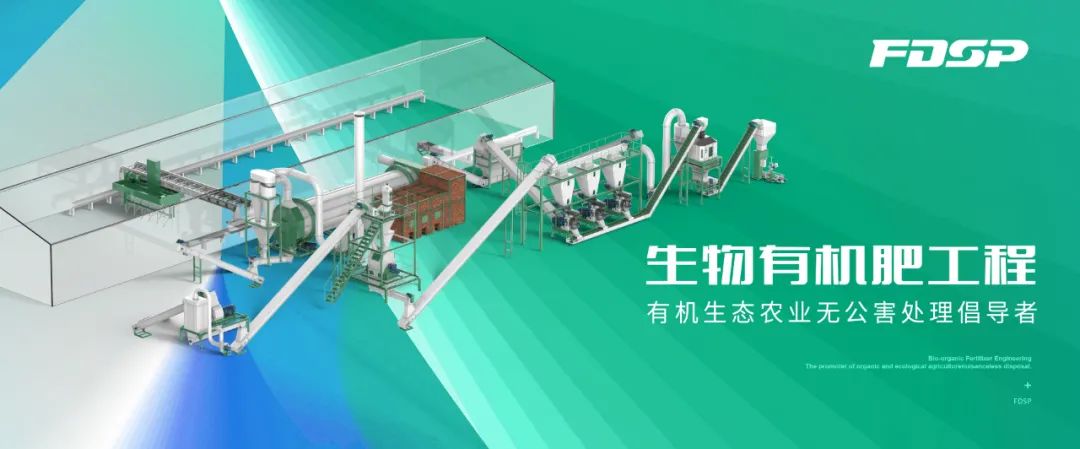

FDSP Quality Engineering Series|Bio-organic Fertilizer Engineering

2024-10-23

About

Jiangsu Liangyou Zhengda Co., LTD. (Abbreviation: FDSP) was founded in 2003, located in Liyang High-tech Industrial Park, Jiangsu Province, on the border of Jiangsu, Zhejiang and Anhui. As a national high-tech enterprise with high growth in the industry, we focus on the research, development, design and manufacturing of bio-organic fertilizer and fermentation fertilizer equipment and engineering. FDSP has made remarkable achievements in the field of granulation technology, forming raw materials such as pharmaceutical residues, straw meal, animal feces, domestic waste fermentation, minerals, etc. After stacking, fermentation, granulation and other bio-organic fertilizer particles, we are inclined to customize personalized solutions for global customers of fertilizer machinery and complete projects.

The FDSP company adheres to the enterprise spirit of "cooperation, creation, honesty and courage", adheres to the core value concept of "winning trust by sincerity and winning victory by quality", pursues the differentiated competition strategy of "creating the big differences in the world of universal harmony", takes customer demand as the core, relies on high-tech products, and takes lifelong service as a commitment. Continuously to create more and greater personalized value for customers at home and abroad, unswervingly to seek "mutual benefit and win-win, common development" with customers.

Bio-organic fertilizer engineering

It takes use of crop waste, organic solid waste, animal manure, and urban food, etc., and producing efficient "organic matter, pollution-free" biofertilisers, to improve the soil environment while transforming waste into treasure, and promote the circular development of healthy organic agriculture.

China has always attached great importance to sustainable agricultural development and ecological environmental protection, and in 2024, the use of bio-organic fertilizer is strongly advocated in the strengthening of black land protection and high-standard farmland construction. Compared with traditional organic fertilizers, bio-organic fertilizers have obvious advantages such as less dosage, protecting arable land, solving soil compaction, reducing weight and reducing drugs, improving quality and efficiency, and green organic planting. It adopts granulation technology, is granular, can be used with fertilizer, fertilization is convenient, accurate fertilization, and effectively improve the utilization rate. At the same time, the functional bacteria and organic matter contained can provide comprehensive nutrition for plants, and the fertility lasts for a long time, helping to improve the soil quality, promote the decomposition of microorganisms, improve the utilization rate of fertilizers, and reduce the amount of fertilizers used.

Bio-organic fertilizer not only reduces the cost, but also increases the benefit, is the best green fertilizer. The best way to achieve results is to use a large amount of bio-organic fertilizer, which is essential to protect farmland and achieve green and sustainable development of agriculture.

The process description

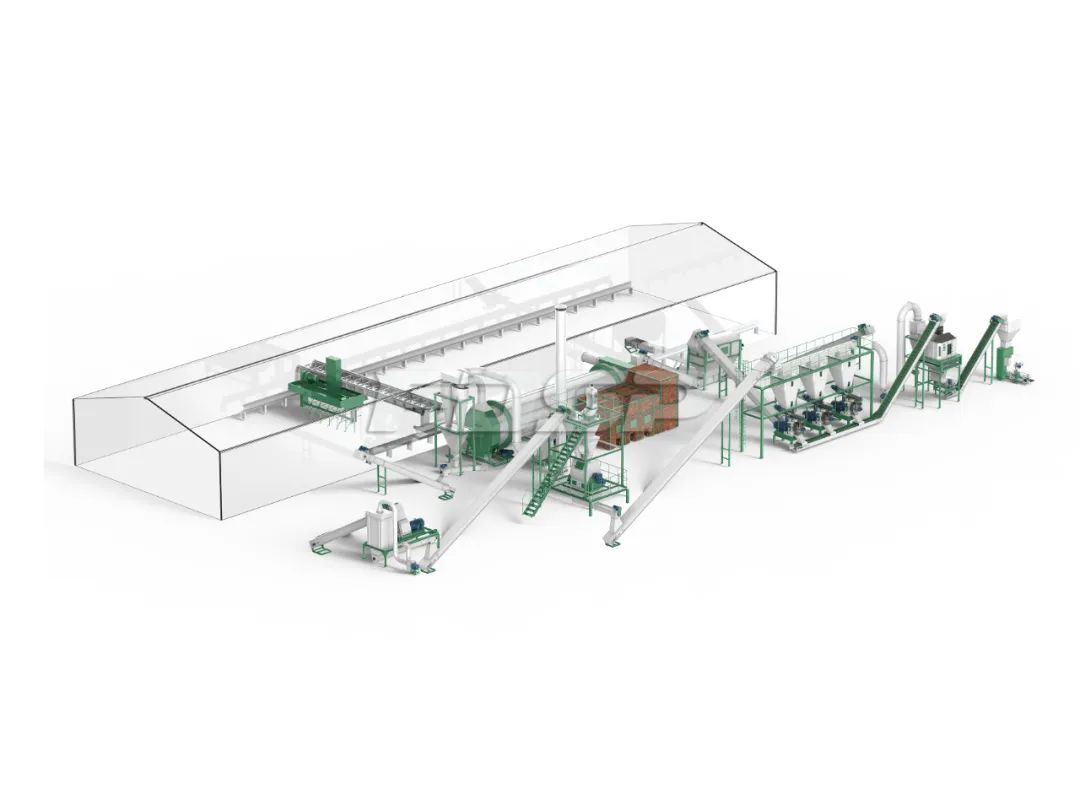

Bio-organic fertilizer pellet line

FDSP bio-organic fertilizer pellet production line is scientific planned and directionally designed. After fermentation, pretreatment section, crushing, mixing, pelleting, cooling screening, packaging and other processes, the finished organic fertilizer pellets are cylindrical, uniform and full, which improves market competitiveness for customers .

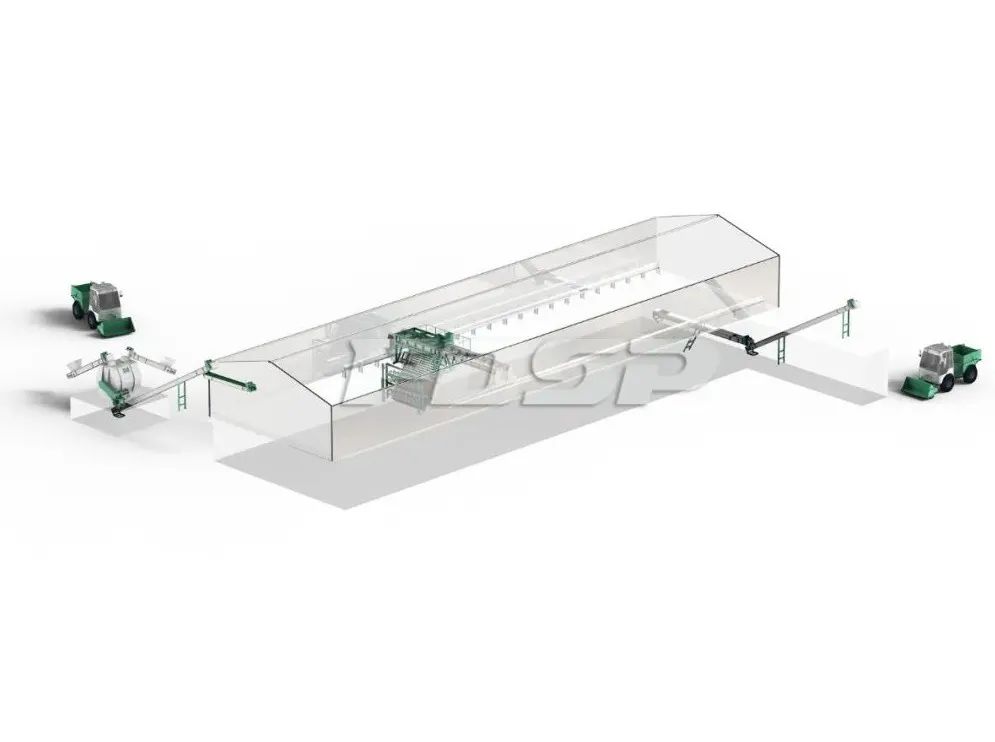

Fermentation process

According to the requirements of different process plants, we scientifically configure single machine or large-span equipment to ensure deep stacking and uniform fermentation of materials. Hydraulic drive lifting mechanism and automatic integrated electronic control system are adopted, which is advanced and flexible, easy to operate.

Pretreatment process

The fermented organic fertilizer raw materials were crushed, screened and dried.

Grinding process adopts synchronous speed of high strength wear-resistant carbide chain plate, greatly improves the service life. The broken material is uniform, not easy to stick to the wall, and easy to clean.

The unique design of drying structure can improve the utilization of heat energy and reduce energy consumption at the same time, and the moisture of raw materials can be effectively reduced to 20% after drying, and the drying effect is excellent.

Grinding process:

The grinding process adopts high strength wear-resistant carbide chain plate with synchronous speed, which greatly improves the service life. Grinding equipment adopts advanced rotor design, can quickly replace the hammer and accurate positioning, saving time and effort. Special treatment of parts are not easily worn and improved life.

Mixing process

Material mixing is efficient, uniform and with no residue. Stainless steel can be selected. Scientifically designed seal and blade arrangement are low energy consumed and easy maintained.

Pelleting process

Fertilizer special pellet mill is selected. According to the characteristics of fertilizer granulation, it is researched and developed. And then it is optimized and upgraded, which greatly improving the yield and molding rate. After Equipped with imported bearings and oil seals, it runs more smoothly.

Cooling and bagging process

It can monitor the temperature of the cooled material in real time, optimize the designed cooling air network, and ensure that the predetermined cooling effect is achieved. An efficient and reliable screening system enables the finished product to meet the needs of customers and the market.

Bagging process: A new generation of intelligent weighing packaging and palletizing system, with ton bags and small bags to be chosen from, which can achieve automatic weighing, automatic zero elimination, and automatic alarm, etc. and saving manpower and material resources.

Electric control system

High degree of automation, with computer full screen control or analog screen central control system, real-time monitoring, so that you can know the operation of factory equipment at any time.

Under the current situation of agricultural development in China, bio-organic fertilizer is ushering in broad prospects for development. With people's increasing attention to food safety and ecological environment, bio-organic fertilizer is more and more favored. As an advocate of pollution-free treatment of organic ecological agriculture. FDSP bio-organic fertilizer equipment can be based on different requirements of customers, different raw materials, different sites, according to local conditions to provide customers with one-stop services from the design of production lines, field visits, equipment installation, commissioning training, maintenance and other services. This can help customers to seize the opportunity in the field of bio-organic fertilizer production and adapt to the needs of the rapid development of the industry.

FDSP bio-organic fertilizer project cases

Bio-organic fertilizer pellet project in Qingdao, Shandong province(4×FZLH420)

Guizhou Moutai distillers' grains organic fertilizer granulation line(FZLH320 single line)

South Korea pig manure organic fertilizer pellet line(6×FZLH420)

Bio-organic fertilizer pellet production line in Laiyang, Shandong province(5×FZLH420)

Biological organic pellet production line in Yantai, Shandong province(5×FZLH420)

Biological organic pellet production line in Jining, Shandong province(6×FZLH420)

South Korea compound organic fertilizer pellet production line(6×FZLH420)