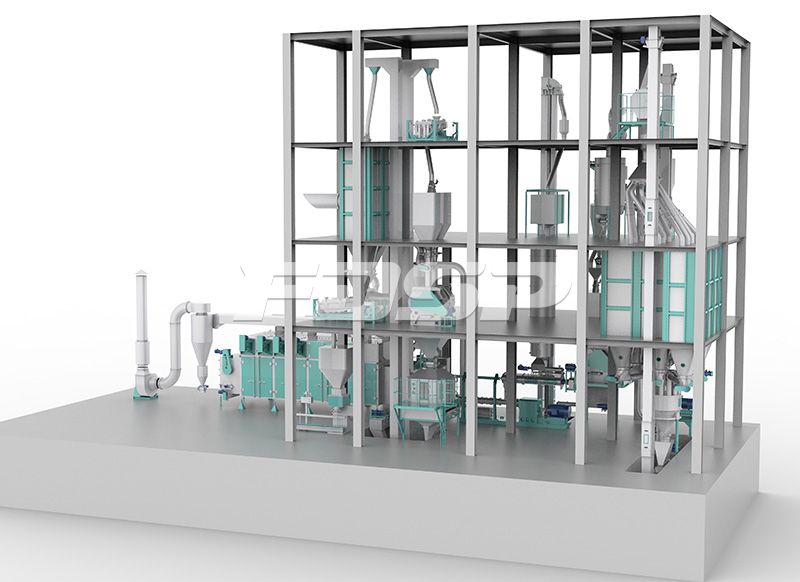

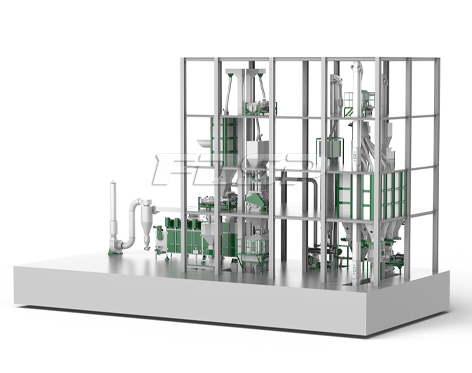

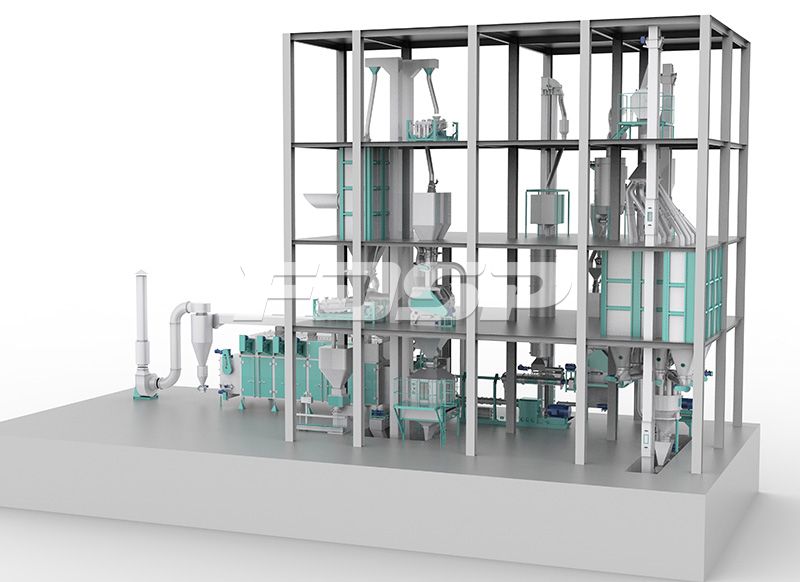

2-3T/H pet food production line

Definition of pet food: pet feed is also called pet food which is the food through industrial processing and production, eaten by pet directly, it consists of pet formula feed, pet additive premix feed and other pet feed.

Jiangsu Liangyou Zhengda Co., Ltd is specialized in manufacturing feed machinery and engineering, we can offer customer complete machine solutions for livestock feed(pig and others) , poultry feed(chicken, duck, goose and others), ruminant feed(cattle, sheep and others), normal aqua feed(four major Chinese carps), special aqua feed(shrimp, crab and others), extruding aqua feed(floating and sinking fish feed, shrimp and others), premix feed(including various additives), pet food(cat food, dog food and others), we can meet customers' kinds of needs.

Now we take the case of 2-3TPH pet food production line, make introduction based on process diagram and each process as follows:

Raw Materials:

The main raw materials of pet food are mainly protein and fat, it consist of wheat, soybean meal, rapeseed meal, rice bran, bran, blood meal, bone meal, meat meal, oil, antibiotics, vitamins and etc.

Introduction of Main Process:

The features of pet feeds are that the crush fineness is small (about 60-80 mesh), the curing degree is high, with high oil content (The refueling way is the combination of mixer, extruder and powder spray three ways), the diameter range of finish pellets is large (about 0.6-20mm). This pet feed mill plant’s capacity is designed to be 2-3tph, adopting batching first then grinding process which means one dosing process, one premixing & grinding process, second pulverizing process, second mixing process, extruding, drying, powder coating, liquid coating, cooling process and bagging process. The total power of this line is about 505kw, the working land size is about 19*12*19m, and matching 1.5ton boiler. The whole line has compact design, reasonable structure and meets the requirement of environmental protection. It can be customized according to customer’s requirements.

Flow Diagram of Process:

RM Receiving & Precleaning System—First batching System--first premixing and Grinding System——second Pulverizing System—Second Mixing System—Extruding System—Coating & Bagging System

Craft features and illustration of Each Process:

As the high oil and fat content for pet food raw material, the regular grinding before batching process will make it difficult for hammer mill to grinding single material with high fat, so usually we adopt batching before grinding process.

Raw materials receiving and cleaning section:In this section, pellet feeding cleaning and powder feeding cleaning are separated independently and separate dust removal. Dust removal effect is good.

Cleaning equipment:granules sifter SCY80,capacity 20-30T/H

First batching section: This section adopts 10batching bins, one set of batching system. It is controlled by the batching program independently developed by our company to realize accurate fast and slow feeding, fast batching and high precision.

Weighing equipment: Dosing scale PCS-05 dosing precision: dynamic ≤3‰, static ≤1‰.

first premixing and grinding section: this section adopts one ribbon mixer to achieve premixing and one hammer mill. efore entering the bins, the impuritiesare removed by magnetic separation device to ensure the safe operation of the hammer mill.

premixing equipment: Ribbon mixer SLHY1,(11KW,500kg/batch), designed output 3-5t/h. Mixture uniformity CV ≤7%

Grinding equipment : Hammer mill SFSP568-Ⅱ, 37kw, designed to produce 3-5t/h(¢2.0mm screen hole)

Pulverizing section: Due to the extruder high requirement for the fineness of raw material, generally 60-80 mesh, this section adopts a pulverizer, adopts the pneumatic type discharging, is allocated with cyclone, pulse filter, and the grinding fineness can be adjusted.

Pulverizer equipment: SFSP668*600, 55kw; Designed output: 2-4t /h.

Second mixing section: This section adopts two secondary mixing bins, one mixer and a micro element adding port.

Mixing equipment: mixer SHSJ1, 11kw, 500kg/P, designed to produce 3-5t /h. Mixture uniformity CV≤5%.

Extruding section: This section adopts a double screw extruder, equipped with a pre-extruding round bin above the extruder and equipped with a disk-type feeder to prevent material from arch and discharge smoothly.

Extruding equipment: double screw extruder SPHS98×2,1.5+5.5+11+110+4+1.5KW(with single conditioner and double shaft differential conditioner ), design output: -3T /H (mould hole diameter 4.0mm), drying equipment: SHGW24×2-6, 0.55+1.5*2+7.5×8+ 0.55kw, design output: 4-6T/H

Coating & Bagging section: This section adopts a set of composite powder and liquid coating equipment, equipped with two weight loss type bin before entering the equipment to meet the ratio control of formula. The coating section solves the problem that the early phase of the material fat content should not be too much and then can not meet the fat content requirements. By coating, the feed appearance is good, palatability is strong, and nutrition is strong. The materials will be screened and packed after cooling by swing cooler.

Coating machine: spraying mixer SHSJ1,(11KW,500kg/P)design output: 2-3T/H, Mixture uniformity CV≤5%.

Swing cooler: SKLB4, 1.1+ 1.5kw, 4m3 volume, design output: 3-4T/H.(extruding feed has small density, large volume)

Packing equipment: Rapid single-bucket granule scale for extruding material, packing range: 20-50kg/bag, 4-6 bags/minute.

Auxiliary section: The dust removal system: it is used in the bagging system which can improving the working environment for workers; Oil adding system and Water adding system: it can improve the feed palatability.

According to the needs of different customers, the scheme can be optimized:

1. This plan adopts batching before grinding process; raw material bins also can be batching which simplify the process, save the cost. the quantity of bins and buffer hopper and be adjusted based on customer's needs, for example: set two intake buffer hopper could reduce the waiting time when batching and improve the efficiency.

2. second pulverizing process could chose pulverizer machine with higher efficiency, smaller particle size according to customer's material condition, but it will increase the cost

3. The configuration of the extruder is a single conditioner + a dual-axis difference speed conditioner. The single conditioner is to add more meat paste and fat, but if customer do not have high requirement for fat content, they can remove the single conditioner to reduce cost

4 The finished product packaging equipment can be customized according to the customer's packaging specifications and requirements. Generally, the finished product packaging of pet feed can be divided into small packaging and large packaging which will use different packing equipment