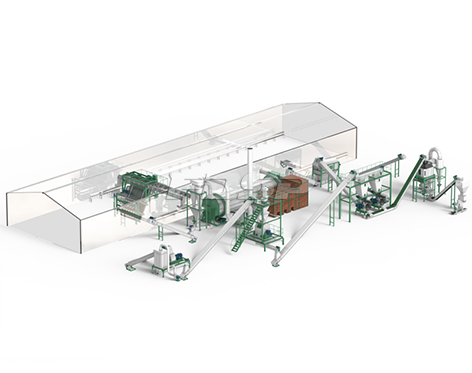

Jiangsu Liangyou Zhengda Co., Ltd. is specialized in producing complete equipment for granulation of bio-organic fertilizer, which can provide customers with complete production lines of bio-organic fertilizer granulation with animal manure (mainly chicken manure, pig manure, cow manure, sheep manure, etc.) as raw materials. Complete production line for granulation of bio-organic fertilizer based on urban kitchen food; The complete production line of bio-organic fertilizer granulation based on urban household garbage; can customize the complete equipment solutions of bio-organic fertilizer to meet the different needs of customers.

Now take the 6-8 tph chicken manure organic fertilizer granulation production line as a case, according to the process and each section to do the following introduction and description.

Raw material

Main is chicken manure, mixed with straw, sawdust or domestic kitchen waste, etc.

Flow process brief introduction

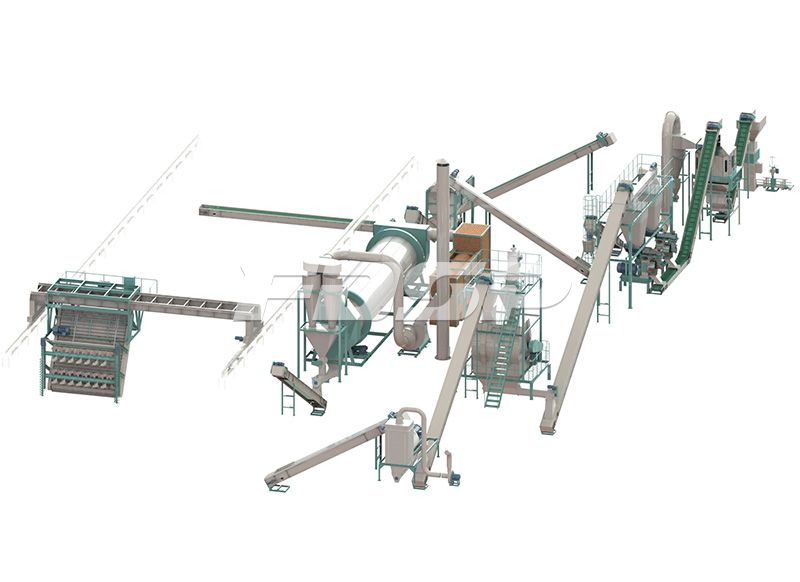

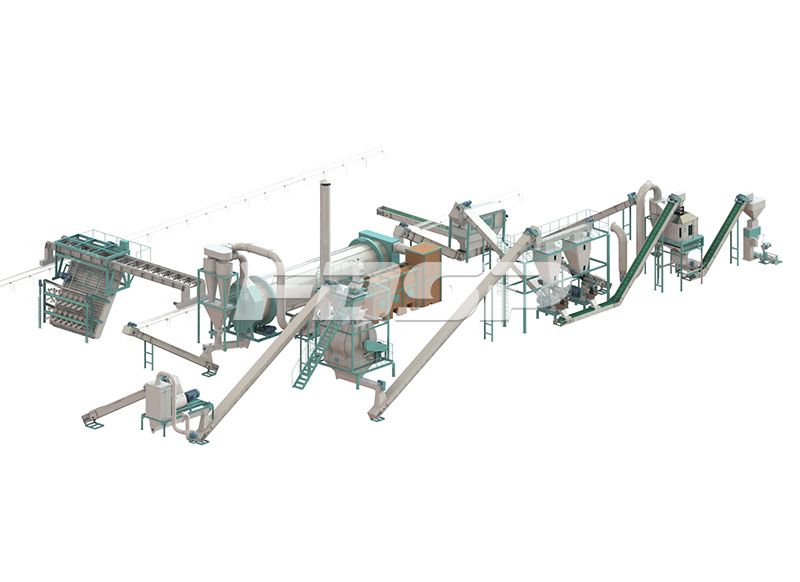

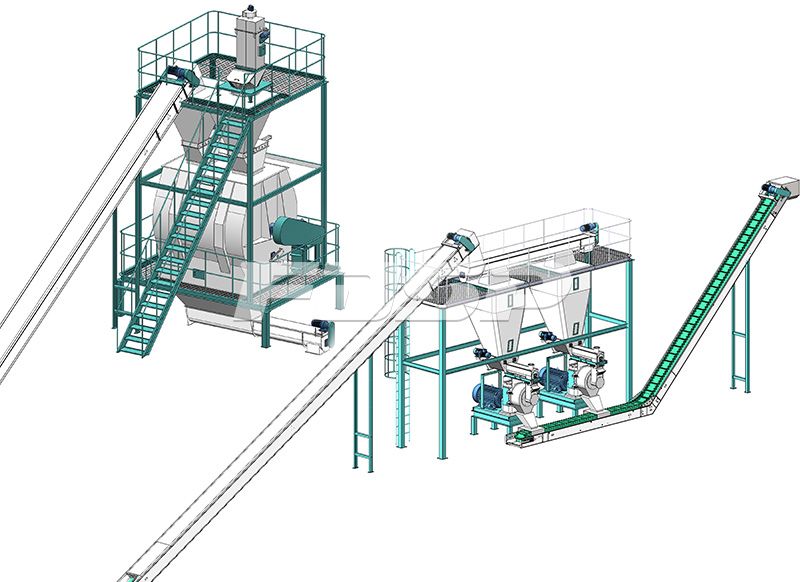

Two Line FZLH508 chicken manure biological organic fertilizer production line is by using of chicken manure to mix with some halm, straw, sawdust, or kitchen waste and other organic compounds on composting, fermentation, drying after pre-treatment, again into the processing workshop, through crushing, mixing, granulation, cooling, packaging section after processing, biological organic fertilizer, when the whole line to produce 6-8 tons of organic fertilizer granules, equipment total power is about 720 kw, the workshop covers an area of 3200 ㎡, contain raw material warehouse and finished product warehouse; The design of the whole line is compact, reasonable, meets the requirements of environmental protection, and can be directed according to customer requirements.

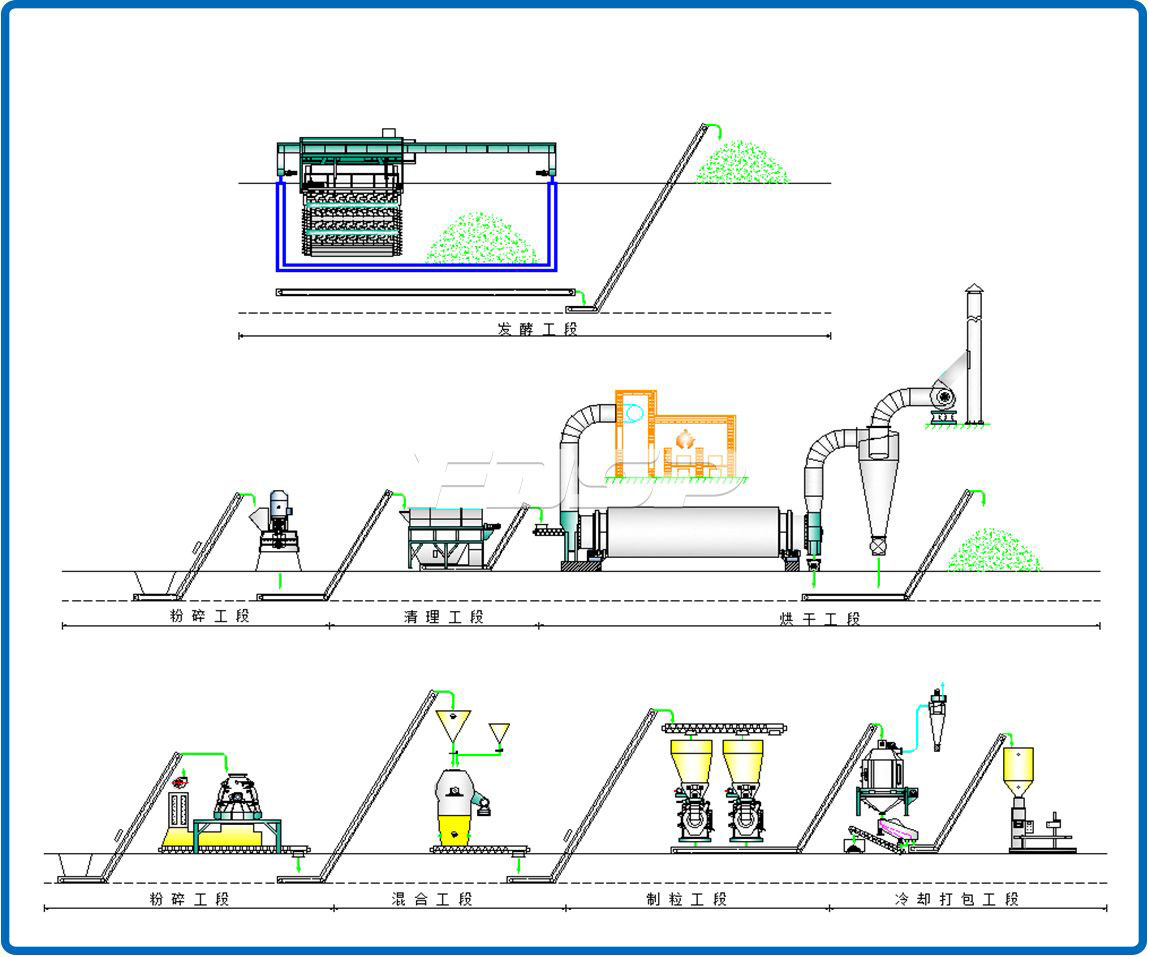

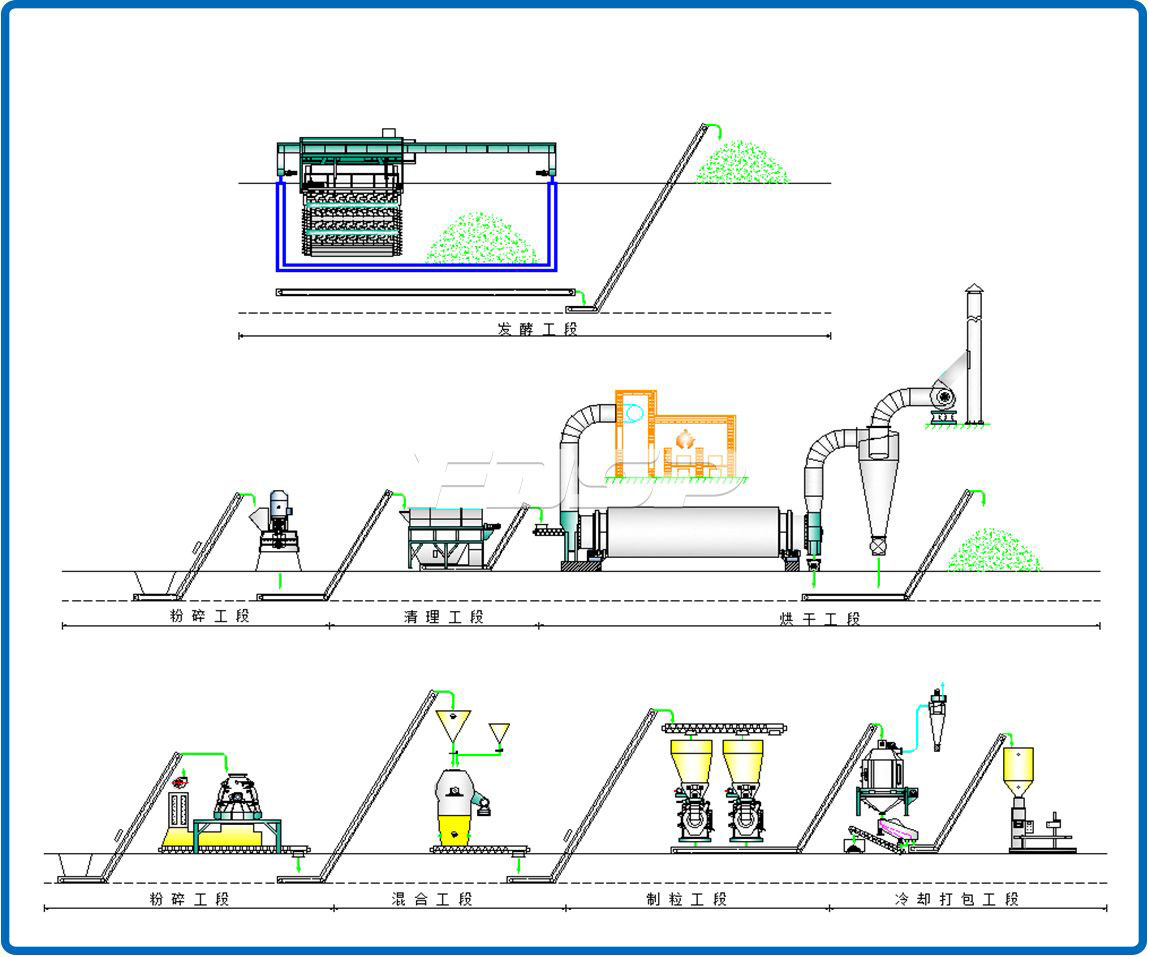

Flow process diagram

Fermentation and compost process→pre-treatment process→grinding process→mixing process→pelleting and bagging process

Craft features and sections introduction:

Fermentation and compost process:

Mix the ingredients in a pile 3 to 4 meters wide, 0.8 meters to 1.2 meters high, length not less than 3 meters. Pay attention to the appropriate fermentation process of oxygen and turns heaps.

Compost equipment: LYLP-6, power 35.5kw, output 600 m3/h.

Pre-treatment process:

The raw materials after fermentation are crushed by the special chain grinder for organic fertilizer. Then use the roller cleaner to clean the impurities in the raw materials, including large pieces of wood, stones, agglomerated materials, etc.; Then use the roller dryer to dry the raw material, drying the raw material moisture to about 20%.

Drying equipment: LYHG2.0*20, roller diameter 2m, length 20m, power 22kw. Designed output:5-7tph

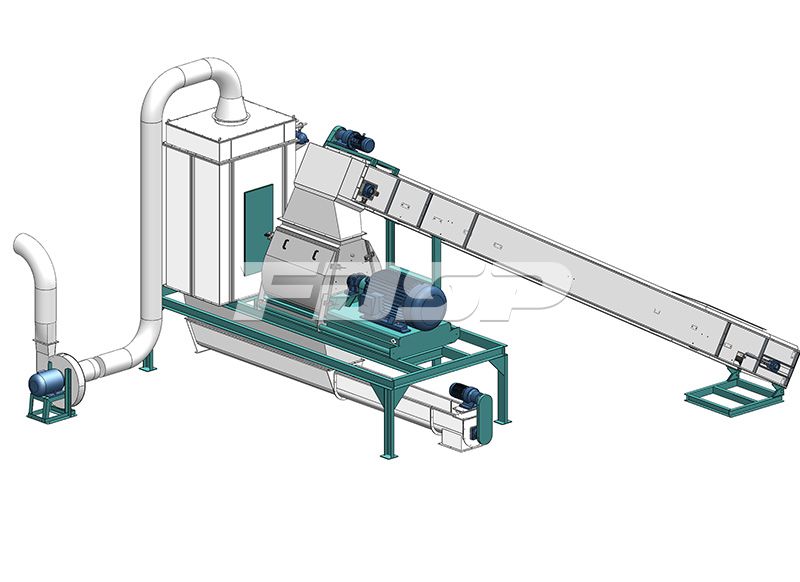

Grinding process:

The materials are conveyed to the hammer mill through the conveying equipment, which is equipped with iron removing device before the hammer mill.

Grinding equipment: FFSP66*100, power 132kw, designed output 6-8tph.

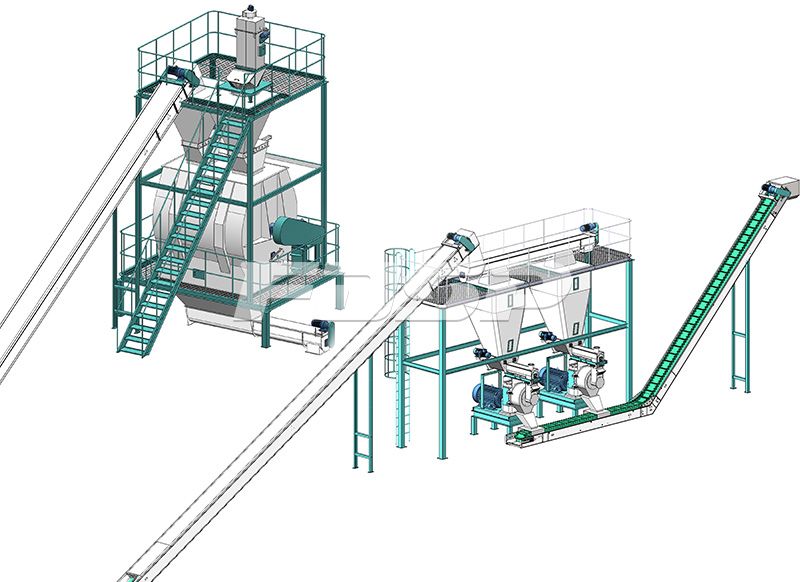

Mixing process:

Through the micro-element adding hopper, the fungus seeds and raw materials can be added to the mixing machine for mixing, after evenly mixed, enters the next section.

Mixing equipment: SDHJ2, power: 22kw, design output: 2m3/batch

Pelleting process: Fertilizer special used ring die granulator, suitable linear speed is more suitable for organic fertilizer granulator, and the adoption of high precision gear drive granulator, high transmission efficiency, ring die with quick unloading type of hoop.

Pelleting equipment: FZLH508, power: 132kw, Design output 3-4tph, quantity: 2 sets.

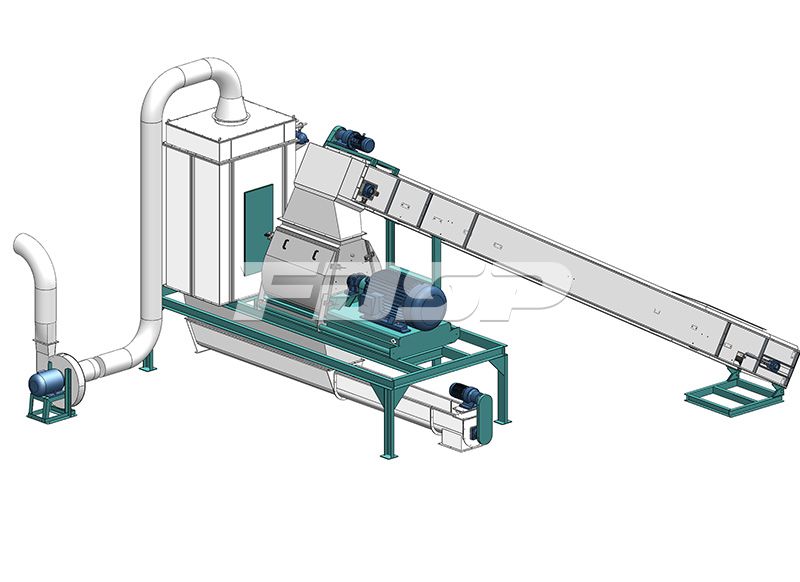

Cooling and packaging section: the tilting type cooler is selected to effectively prevent particle breakage. The cooler is equipped with vibrating grading sieve to screen out some unformed powder. According to the local sales needs of the customer, the packaging scale can be selected to facilitate the customer to sell products. The packaging specification of the packaging scale is: 20-50kg/ package.

Cooling equipment: FKLB4, cooling chamber capacity 4m3, designed to produce 6-8tph.

Packing equipment: FDBLY-PD belt scale, packing range: 20-50kg/ bag, 6-8 bags/minute.

The main functions of chicken manure biological organic fertilizer are:

1. Produce a variety of enzymes to inhibit multiple soil-borne diseases such as stubble disease, root-knot nematode disease, blight, bacterial wilt and blight.

2. The high-efficiency and beneficial microbial flora is continuously active, which can activate nitrogen in the air, decompose and release insoluble phosphorus and potassium nutrients.Replenish soil organic matter and slowly release nutrient elements for crop growth.

3. Improve the soil physics, keep the soil soft and easy to cultivate, promote soil aggregate structure, increase soil pores and promote root group growth.Increase soil water and fertilizer retention capacity, reduce leaching loss.

4, Green environmental protection, improve the efficiency of fertilizer. This product ferments the organic fertilizer to have no toxic side effect, to the crop and the soil environment safety, with the inorganic chemical fertilizer mixture also enhances the use efficiency of the chemical fertilizer, saves the cost.

5. Strong roots, strong seedlings, disease prevention and resistance. A large number of beneficial microorganisms secrete hormones, polysaccharides and other metabolites to the outside world, inhibit the breeding of soil pathogens, promote the development of crop roots, growth, reduce the spread of various diseases.