When building a new aquatic feed processing plant or reforming the old feed production line, the type of extruder should be considered firstly, and a suitable extruder should be selected according to the feed production capacity. Especially in the old plant transformation, should also consider the original hammer mill, dryer and cooler’s production capacity is enough. When choosing, we should consider a few questions emphatically.

1. Extruding effect of the extruder

For aquatic feed, the good extruding effect is that the particle forming rate is above 99%, the particle powder rate is less than 1%, the particle floating rate (sinking rate) is 100%, the particle size is uniform, the color is consistent, with good water resistance; The floating aquatic feed keeps 10h in the water, and the sinking aquatic feed keeps 3h unbroken in the water.

2. Investment price of extruder

The equipment investment cost of twin screw extruder is 1.5 ~ 1.7 times than that of single screw extruder with the same production capacity. The cost of wearing parts is about 1.5 times than that of a single screw extruder. The power consumption is also about 1.5 times than that of a single screw extruder.

3. Service life of extruder

Different manufacturers of extruder due to the different structure characteristics and the use of materials, the service life is not the same. Therefore, in the selection of extruder, we should pay special attention to the wear resistance of some quick-wear parts, as well as its structural design is reasonable, whether can achieve the purpose of reducing screw wear. In addition, it is necessary to consider whether the extruder can really achieve the purpose of energy saving and consumption reduction. For the powder type raw materials without micro grinding, the wear of the quick wear parts will be more serious, especially for the twin screw extruder. For this situation, it is more reasonable to choose a single screw extruder.

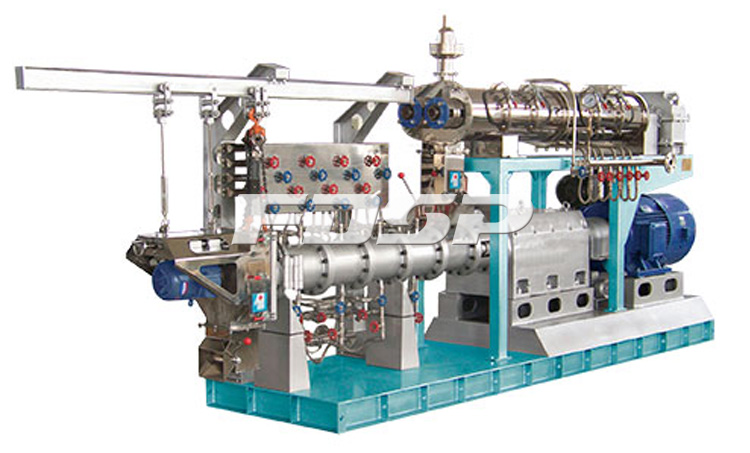

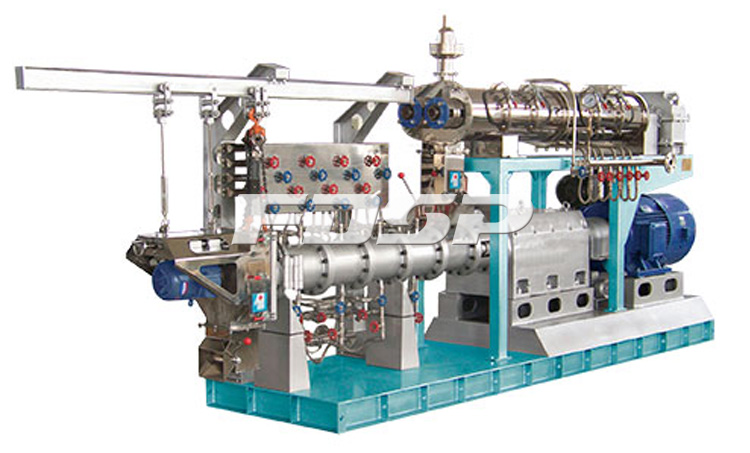

Liangyou stock is a professional feed machinery processing equipment and the whole plant engineering comprehensive problem solver, the quality of the extruder is trustworthy, stable and efficient, welcome your consultation!