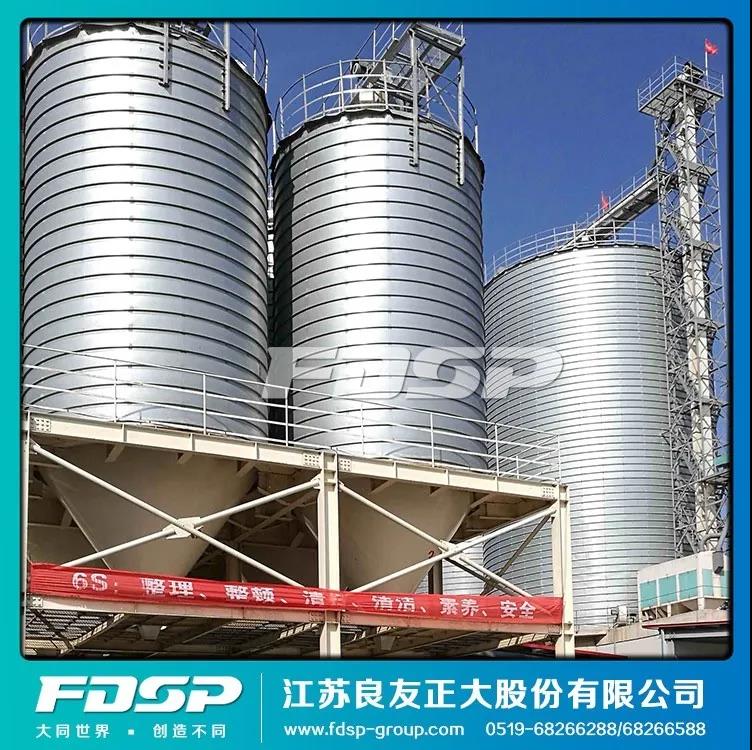

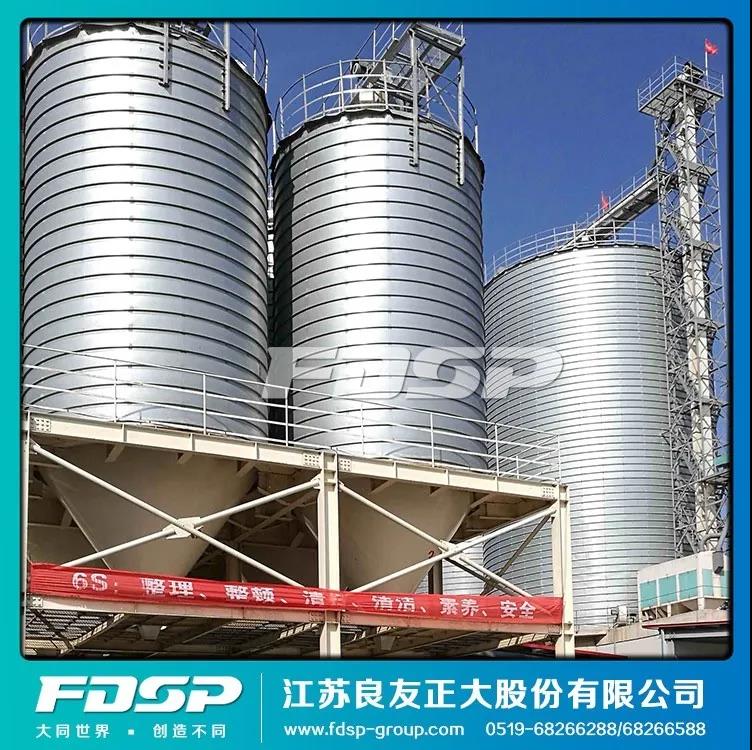

As a storage tool, the main function of steel silo is to store cement, coal ash, grain, feed, grease, etc. After more than 30 years of development, it has become popular all over the world, widely used in all aspects of storage and transportation, and has become a modern symbol of bulk and bulk storage in various industries. The advantages of steel silo have laid the foundation for its rapid development.

Compared with traditional warehouses, steel silo has obvious advantages, mainly including the following points

1. Low operating energy consumption. Because the steel silo adopts the design concept of gas fluidization, gas homogenization, gas flow and mass flow transportation integration, that is, the principle of one gas for multiple uses, a large amount of gas source can be saved. Considering that the cement storage period is longer and the capacity is increased, medium pressure air is used as the air source for unloading, and the low pressure air source of Roots blower is used for the central area and the delivery pipe.

2. Good effect of storing materials. The materials are basically input and vacuum sealed in the tight air isolation on the wall of the large steel silo. This sealing effect is much better than that of brick, stone, and concrete structures.

3. Low carbon and environmental protection. The top of the steel silo is a load-bearing dome, and the top of each silo is equipped with a pulse vibration dust collector, which mainly collects the dust generated when the material is put into the warehouse, so that the dust emission concentration can reach 30mg/m3 or less.

4. Flexible process layout. According to the actual situation of the site, it can be arranged in a line, triangle, double row or multiple rows and other layout forms. The direction of the discharge corridor can be determined according to the site situation. It is free and flexible to meet the various needs of customers. Since the upright pipe is used for discharging, the position of the outbound hoist can be freely selected.

5. Wide storage usage. It can store cement, clinker, slag powder, fly ash, etc., which not only reduces investment and eliminates environmental pollution, but also saves a lot of construction land.

6. Short construction period and long service life. According to the geological conditions and site environment, the construction period of steel silo is generally about 4 months. If it is construction of warehouse group, it can be cross-construction or simultaneous construction, which greatly shortens the construction period. If the anti-corrosion maintenance is carried out according to the specifications, only the anti-corrosion paint needs to be painted every few years, and a reliable service life of 30 years can be guaranteed without obvious corrosion on the outside, while saving maintenance and protection costs.

7. Low maintenance cost: There is almost no maintenance cost for the discharge equipment in the warehouse.

Liangyou has a wealth of construction experience and a formal construction team, and has integrated steel silo research, development, design, construction, adjustment and service for many years. Whether at home or abroad, we have a wealth of steel silo equipment and storage system engineering cases. Professional design, professional manufacturing, professional installation, allowing customers to truly experience the quality of Liangyou steel silo and one-stop comprehensive service is our constant pursuit.