Reducing costs and increasing efficiency has always been one of the effective measures for feed companies to gain competitive advantages, especially in a relatively fierce market environment, to effectively save production costs and improve their own benefits to achieve stable and sustainable development. It is particularly important to choose a professional feed plant design and contractor, because from the plan design to the installation, it will affect the future cost reduction and efficiency improvement of the entire production line.

For investors, the first consideration in the early stage is how to reduce the initial investment, which includes not only land construction costs and equipment procurement costs, but also long-term equipment maintenance costs in the future. For the contractor, it is necessary to ensure the quality of the equipment and meet the needs of the customers, so that the customers can put them into production and use in a timely manner to obtain profits.

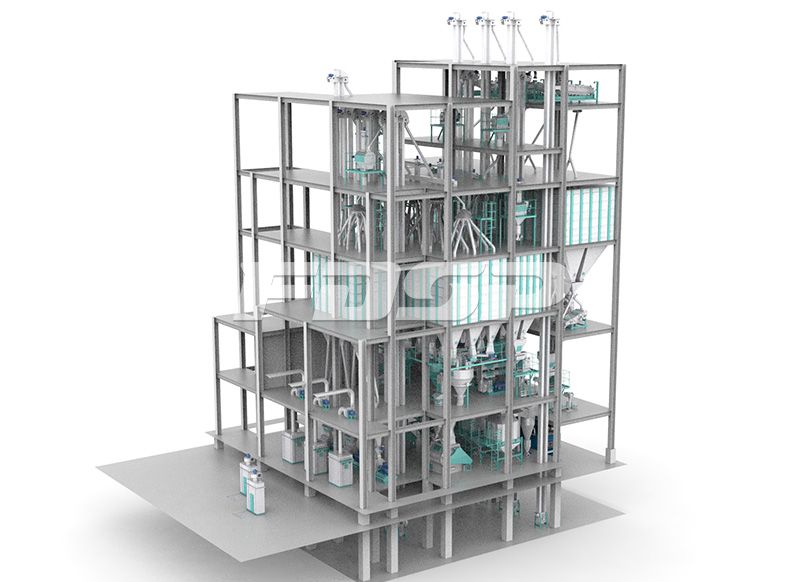

3D layout of FDSP feed production line

The “cost reduction and efficiency increase” in the early stage of feed factory construction needs to be considered:

1. Investors should do a good job of market research before building a feed factory, determine the feed category, avoid blind investment, and choose more promising feed categories based on local market conditions.

2. Reasonably determine the building structure of the production workshop. As feed production requires high plant environment, concrete structure has always been the main mode of choice for feed mills.

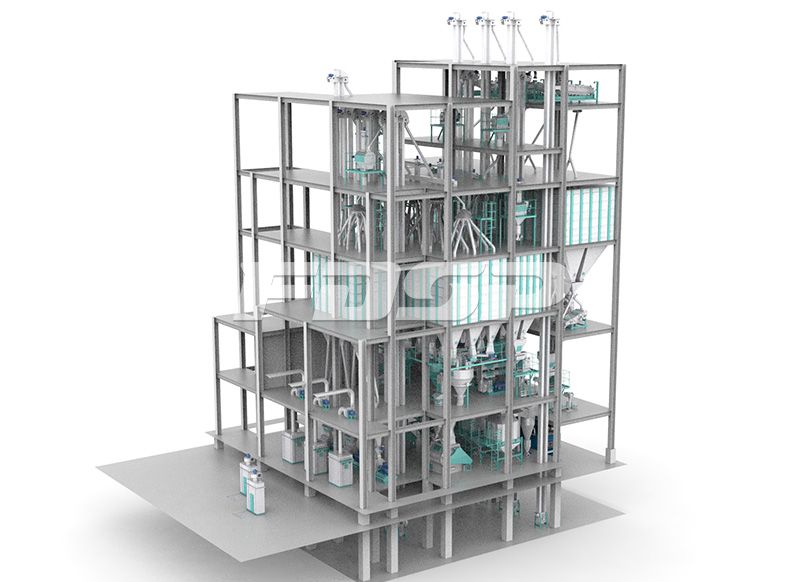

FDSP feed engineering case

3. Choose professional and reliable partners to customize production processes and complete sets of equipment that meet their own conditions.

The design of the production process flow directly affects the follow-up equipment purchases of the feed manufacturer and the long-term production benefits. The process flow needs to be scientifically designed and reasonably planned. Secondly, the selection of production equipment is also a key factor related to the quality of finished feed products and the level of production costs. The selection process should be based on "high efficiency and low consumption" and "improving man-machine efficiency" as the construction principle to avoid mismatch between equipment and production requirements.

4. In the equipment installation process, pay special attention to the correct installation, protect the equipment, and reduce collision and damage. If there is running, spilling, dripping, or leaking during debugging, it should be treated in time, which will reduce subsequent maintenance costs and achieve long-term cost reductions. effect.