Features:

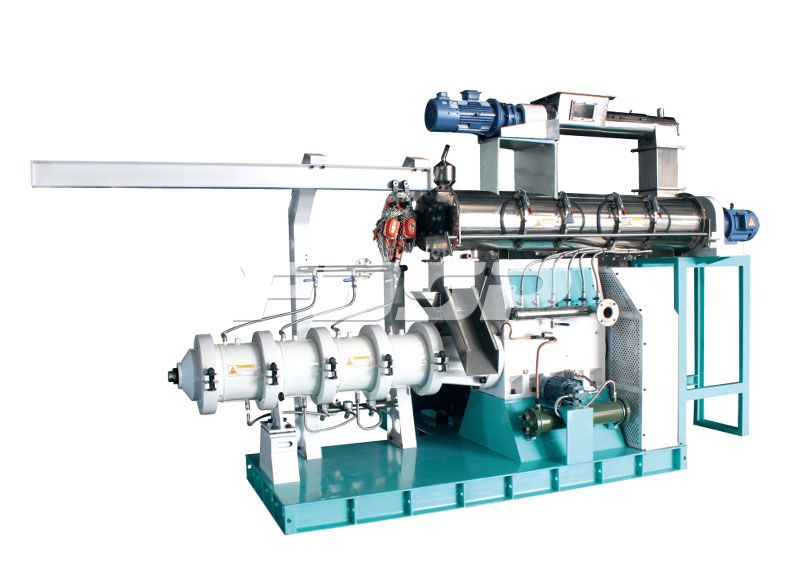

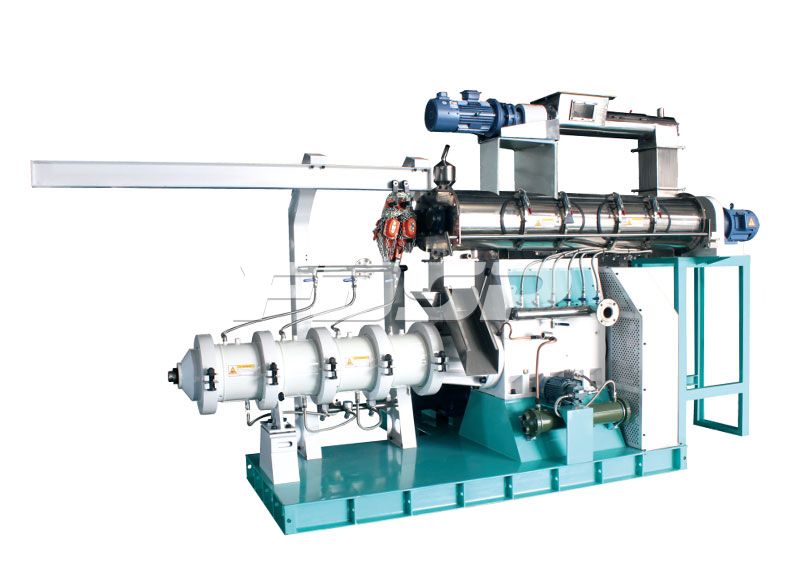

■ Widely used in the extruding of feed ingredients such as soybeans, corn, soybean meal and the production of slice suckling pig feed;

■ Equipped with different types of conditioners to adapt to the extruding process of many different products;

■ This machine is equipped with a special frequency conversion speed feeder, which fully guarantees the smooth and pure material entering the conditioner. The connection of the feeder and the conditioner can be changed according to the overall layout of the workshop production line, which makes the process smoother.

■ Unique transmission box structure design, no need for external cooling system to ensure stable and reliable transmission;

■ Wearing parts are made of special alloy steel materials to extend service life and reduce customer cost;

■ Real multi-purpose equipment, customers only need to replace a small number of parts, can simultaneously produce different characteristics of raw materials such as puffed soybeans, puffed corn and flakes, and reduce customer costs;

■ It can sterilize, detoxify, mature, improve quality and improve digestion and absorption rate, while avoiding cross-contamination of the entire process;

■ It adopts three-bearing arrangement design and circulating thin oil lubrication to ensure the stability of equipment operation and the service life of bearings.

■ Productivity is increased by 15% to 20% compared to similar models.

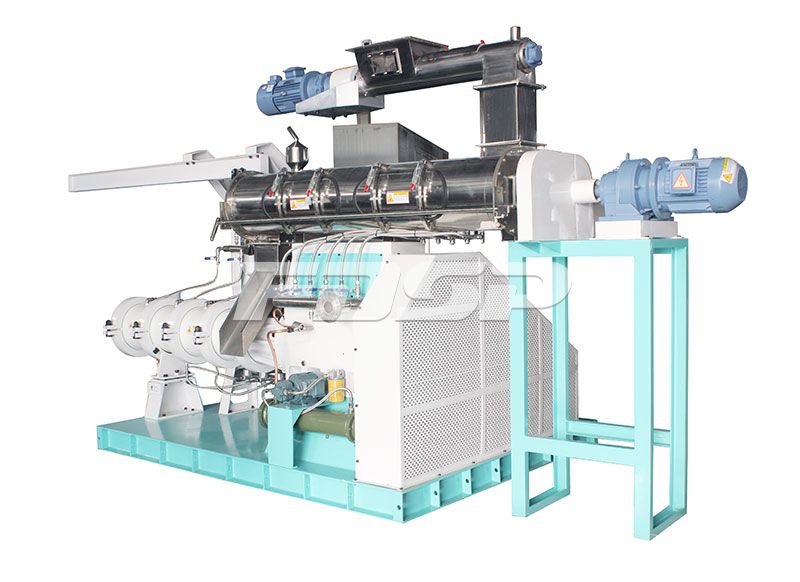

■ High efficiency conditioner

Stainless steel lengthened jacket structure, frequency control;

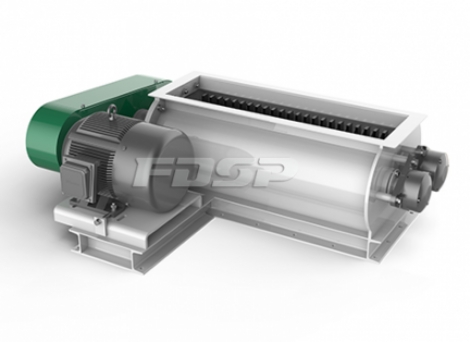

■ Frequency control feeder

Accurate feeding, stable flow, anti-bridge;

■ Optional combined main shaft

It can be adapted to puffing and processing of different materials, especially suitable for puffed soybeans, puffed corn, puffed livestock and poultry materials; and widely used in rice bran preservation, cotton detoxification treatment;

■ High production efficiency

Compared with similar models, productivity is increased by 15% to 20%.

■ Wide range of applications

Adapt to a variety of production processes. The spiral is a sleeve type single head and double head exchangeable; the steam conditioner is a double shaft differential speed structure, ensuring that the material can be fully preconditioned. The discharging method has various structural alternatives according to different production requirements, and can be adapted to the puffing processing of a various kinds of different feed products.

■ Precise feeding, anti-bridge

This machine is equipped with a special frequency conversion speed feeder, which fully guarantees the smooth and pure material entering the conditioner; the connection of the feeder and the conditioner can be changed according to the overall layout of the workshop production line, so that the process flow is smoother.

■ High production efficiency

The feed mill can be used for raw material processing, such as detoxification treatment of puffed whole-fat soybeans, puffed soybean meal, puffed corn and cottonseed meal (or rapeseed meal) (different processing objects, different configuration forms); or as a super conditioner before granulation to form a "expansion-granulation" section together with the granulator to produce high quality livestock and poultry feed or aquatic feed.