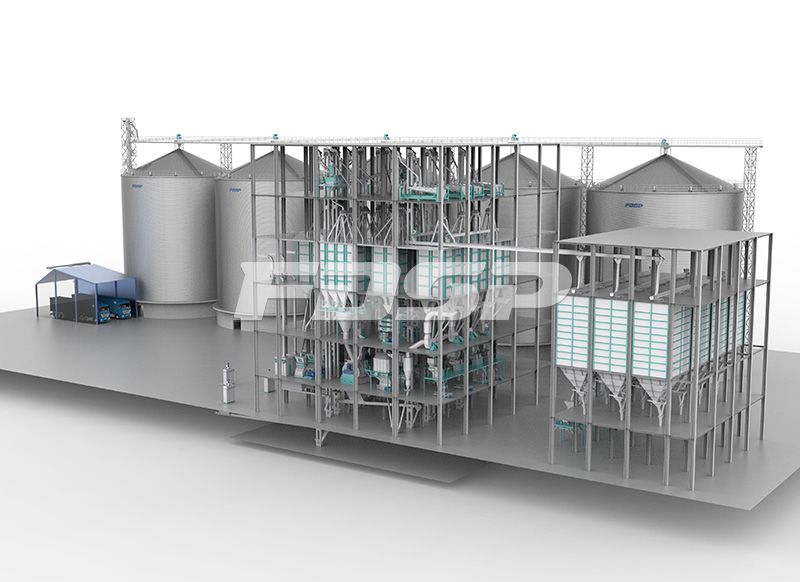

150tph corn deep processing line

1.silo storage section

The raw material corn used in this production line are all imported, each supplement is with large amount and long period. Large amount of corn need to be unloaded into silo after short distance transportation from port unloading to factory. Here we use 5 silos with 8000T each to store the corn, and the unloading system uses 2 unloading intake, the output can be up to 300 tons per hour. The grain unloading adopts indoor closed unloading, and the top of the unloading shed is equipped with centralized dust removal system to prevent the dust produced in the unloading process from floating out and polluting the environment. Steel silos are flat bottom assembled silos, each silo is equipped with independent temperature measurement and ventilation system, all automatic control, to prevent corn mildewed and other accidents during storage.

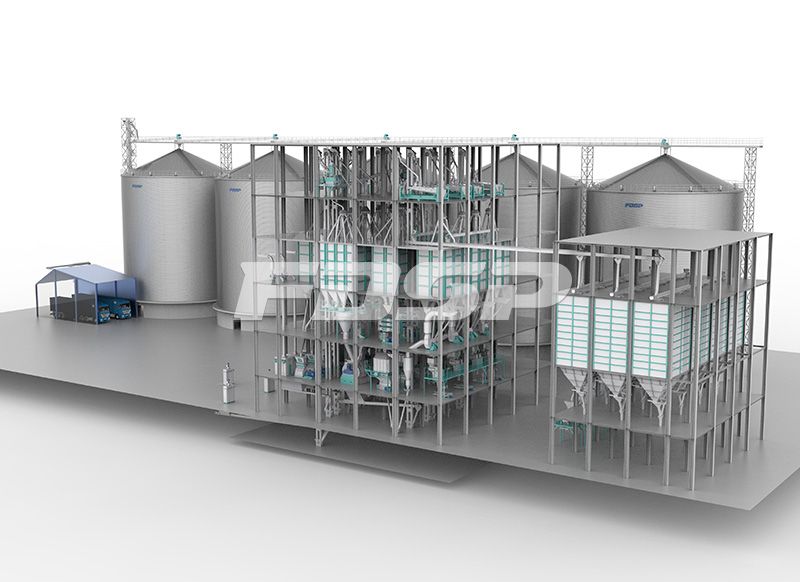

2.Raw material grinding section

Open the automatic gate for crushing bin, the material will be grinded in the hammer mill, the inspectors should carry out particle size inspection at this time, crushing fineness requirements 100% through 20 mesh screen, more than 95% through 40 mesh screen. The crushed material is conveyed to the bucket elevator by the screw conveyor. The noise of hammer mill is controlled according to the national standard: the allowable noise value is 85dB when the worker operation time is 8H, the allowable noise value is 93dB when the worker operation time is 4h, the maximum noise value is not more than 115 dB. Dust concentration not exceeding 10G/M 3. After ventilation and dust removal, the dust concentration of exhaust air is not more than 150MG/m3.

3.Batching and mixing process

The bucket elevator sends the material to the mixing bin, when the slide gate of the mixing bin opened, and the material enters the double shaft paddle mixer, qualified premix and phospholipid oil can be fed by intake now to make mixing. The dynamic batching accuracy of batching system is not more than 3‰ , while the static batching accuracy is not more than 1‰ . The mixing time of the mixer is 60-180 seconds. Inspector should check the mixing uniformity at this time. The CV of the mixing uniformity should not be more than 5% . The uniformly mixed material is sent to bucket elevator by the chain conveyor.

4.Pelletizing section (auxiliary feed line, reserved)

The bucket elevator sends material to the pelleting bin, opens the gate, the material enters the ring die pellet mill to be pressed into the pellet; the requirement for granulation: the inlet air pressure is about 0.4 mpa, the material moisture content is controlled on 16-17% , the granulation temperature is 80-90 °C and the pulverization rate is less than 10% .

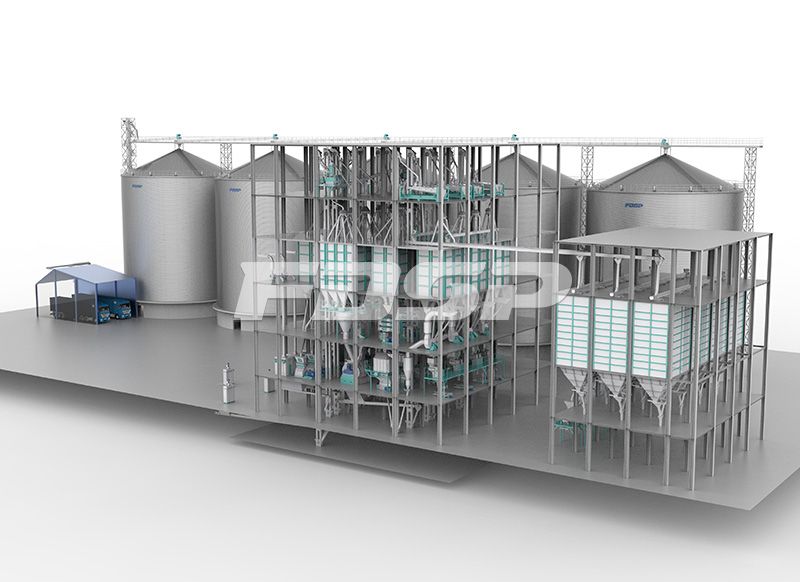

5.Cooling section(reserved)

The pellets will be cooled in cooler, the required water loss rate should be more than 80% and the moisture content of the finished product should be less than 12%

6.Crumbling and screening section(reserved)

After cooling, if the pellets need to be broken, it will go to crumbler for breaking, and then it can be screened in rotary screener, and the screened material will go to packing bins.

7. finished product weighing and packing /bulk section

Adjust the automatic quantitative packing scale, weighing and packing the finished product according to the requirements, control the packing weight of each package in 40 ± 0.2 kg. Quality assurance department could make the finished product sampling and inspection at this time, the final products will be stores after qualified.

The material is transported to the bulk bin by the control switch, and loaded and packed through the bulk truck.

8. Other ancillary systems for corn deep processing line

1. Conveying equipment

There are two kinds of conveying equipment: vertical conveying and horizontal conveying. Vertical conveyor with bucket elevator, horizontal conveyor with chain conveyor, screw conveyor and screw feeder.

The whole production workshop is equipped with 15 units bucket elevator, 10 units chain conveyor, 5 units screw conveyor, 32 units screw feeder, 4 units impeller feeder. 15 units bucket elevators are used to lift the raw material into the workshop, lift the crushed material, lift the mixed material and lift the finished pellets. 2 units chain conveyor used to feeding transportation, 2 units chain conveyor are equipped under the mixer and other chain conveyors are used for conveying bulk final products. Above the 4 batching scales arranged by 32 screw feeders, In which 14 units above small scale and 18 units above the large scales. Four impeller feeders.

2. Workshop production dust removal system

The dust removal system of the production workshop adopts the traditional system including a dust cover, a cyclone separator, a centrifugal fan and corresponding pipes. One set for Finished product packing, with four suction points; each 1 set for cooler suction points, with total four sets. Intake is equipped with single dust collection air net system.

3.Control system

The control system of the production process is carried out according to the production design specification of the feed factory. The batching scale and mixer are controlled by automatic centralized control. Hammer mill, granulator, packaging machine, dust removal system are on-site controlled by hierarchical control system.

4.Liquid(oil) adding system

When oil is added to the tank, adjust the heater to heat the oil to 60-80 degrees (depending on the viscosity of the oil), the system can add oil at this time.

9. Measures to prevent cross-contamination during the production of different products in corn deep-processing production line

1)Production department personnel should coordinate with each other, Make reasonable arrangements for different types or different formula feed production order to prevent cross-contamination, quality control should strengthen supervision and inspection to prevent the occurrence of problems.

2)After one kind of product is produced, the entire production line (from feeding to packaging) or production system (including the dust removal system, batching system, mixing system, buffer bin, conveyor, bucket elevator, bins) should be thoroughly cleaned, to prevent the cross-contamination of subsequent product in the production process .

3)The raw materials should be cleaned up in time once received, and the conveying equipment should be idled for more than 2 minutes to ensure that all raw materials in the process of transportation do not cross pollution;

4)After each class, each kind of material crushing finished, the hammer mill and hopper should be cleaned in time;

5)Inspect conveying equipment, bucket elevator, mixer, granulator and other equipment Regularly to prevent material accumulation, plugging, leakage, in order to prevent cross-contamination of raw materials or finished products in the equipment;

6)Make detailed record for raw material stored in different bins, the bins should be cleaned when change the raw material to prevent cross-contamination.