Introduction about bolt silo:

fabricated by good quality hot-dip galvanized steel sheet(mass of Zn coat could be: 275g/㎡、350g/㎡、450g/㎡), adopt full automatic corrugated plate production line. The diameter of bolt silo could varied from φ2.75m toφ27.5m, height of straight part could varied from 1.12m to 20.16m, the storage volume could varied from 11m³ to 13333m³.

Temperature measuring system, ventilation system, indicator level system, circulation fumigation system inside the silo could be optional according to customer's need.

Based on the carried material, the silo could be divided into: maize steel silo, soybean steel silo, wheat steel silo, barley steel silo, sorghum steel silo, soybean meal steel silo, sawdust steel silo, biomass pellet steel silo. Also we can customized flour steel silo, cement steel silo, building materials steel silo;

Based on the hopper type, the silo could be divided into: concrete flat bottom steel silo, concrete cone hopper steel silo, steel structure support steel silo(single silo capacity should less than 1500T) .

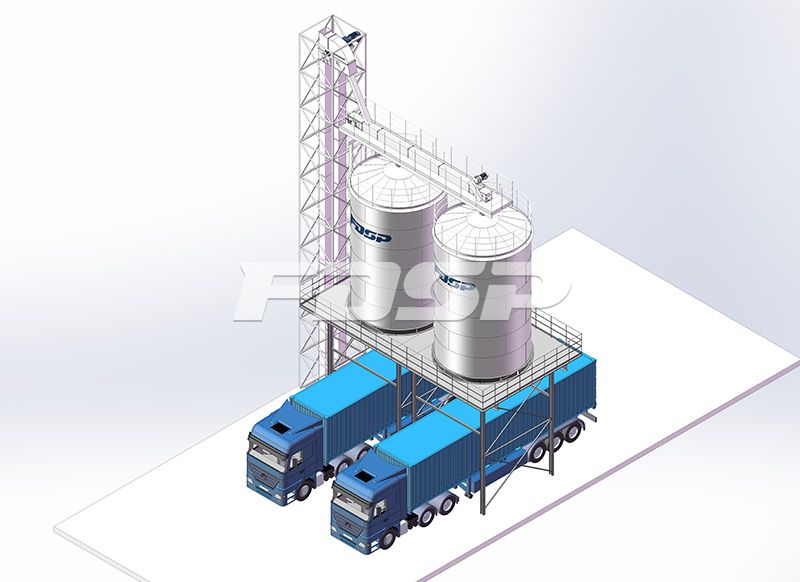

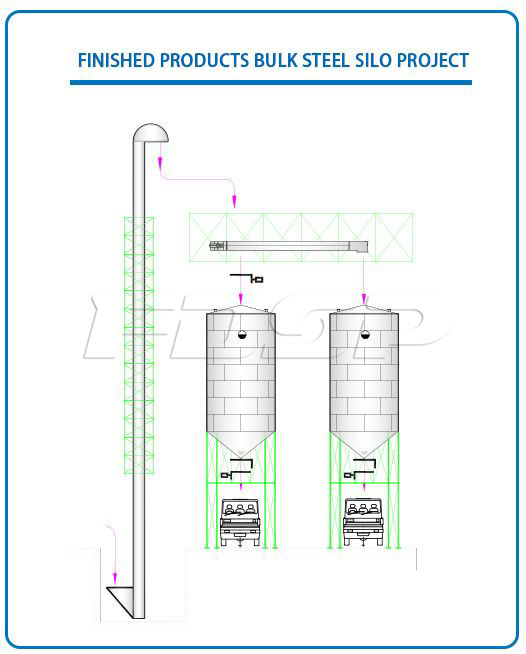

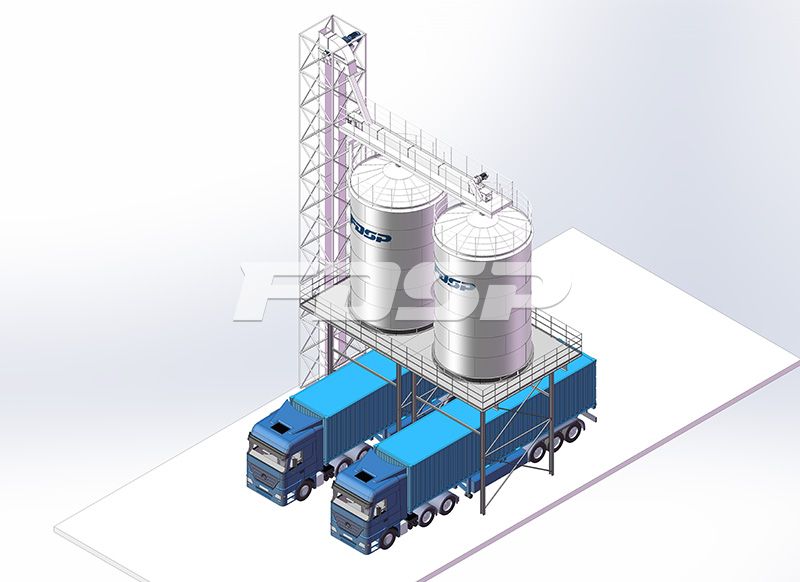

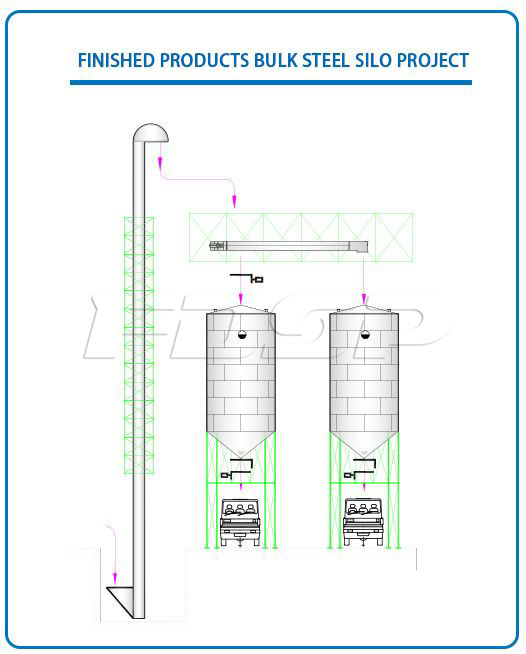

Project instruction:

This project is Finished products bulk steel silo project, the technological characteristics are as follows:

The main materials in silo are products from previous production line such as feed pellets(or mesh feed), biomass pellet, material in large silo .